Continuous infrared drying machine for fruits and vegetables

An infrared dryer, fruit and vegetable technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of difficult movement, heavy barrel weight, and reduced drying efficiency of infrared dryers, and achieve convenient maintenance , the effect of labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific examples.

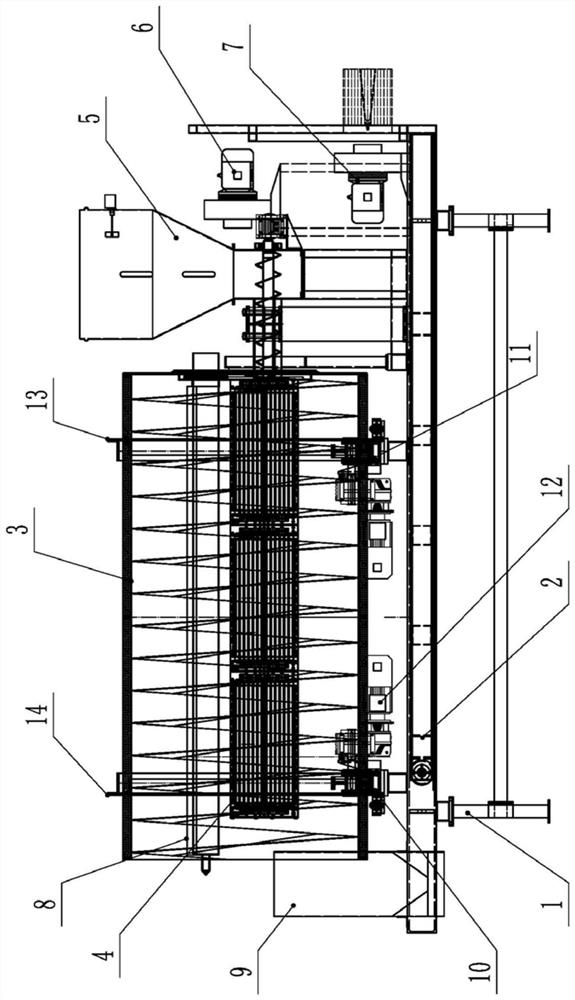

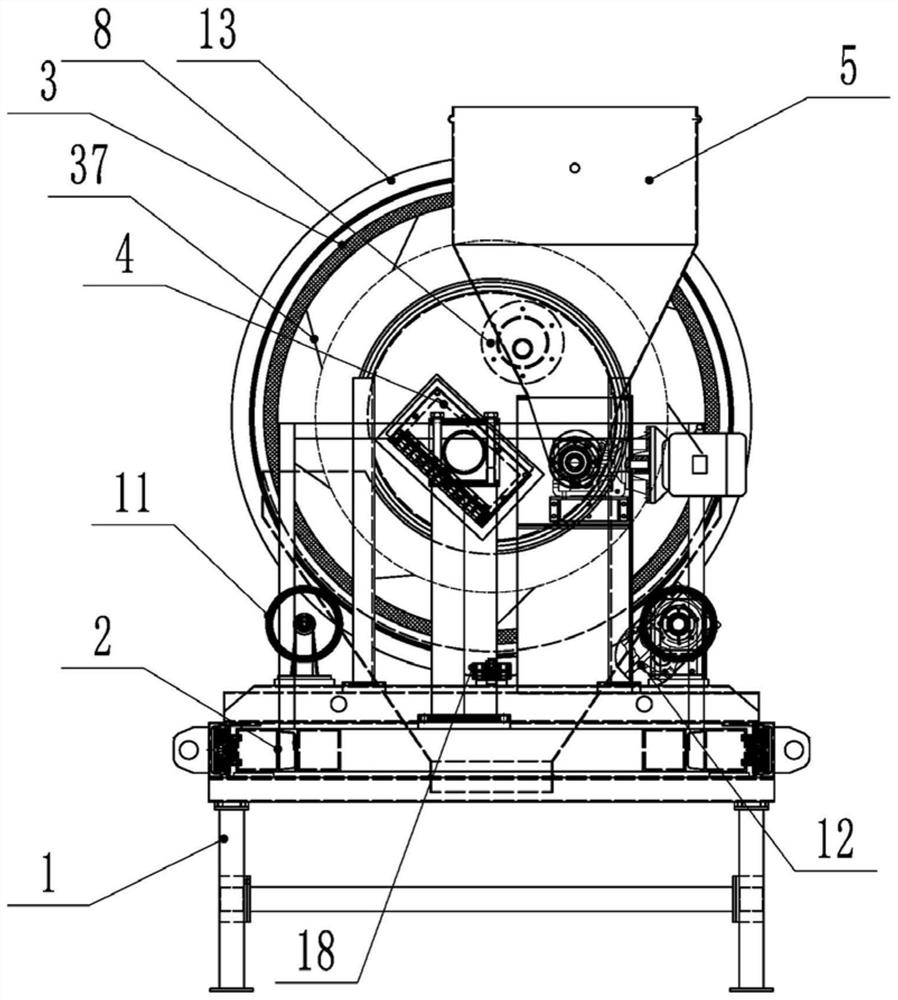

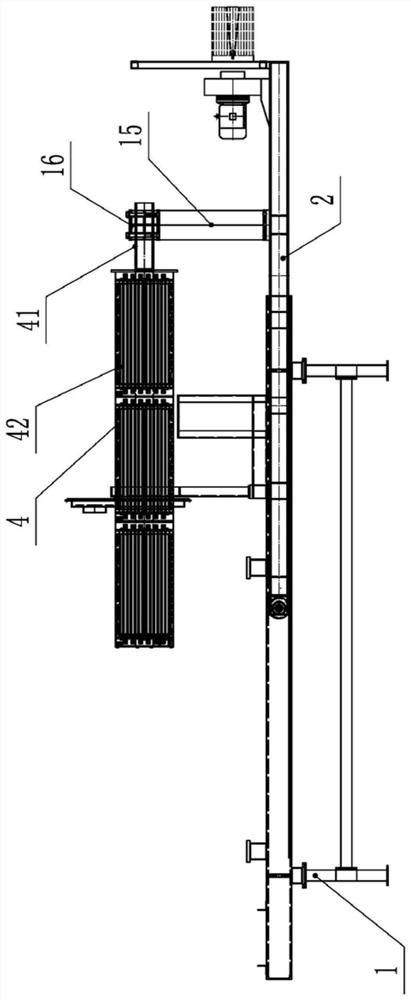

[0030] Such as Figure 1 to Figure 12 As shown, a continuous fruit and vegetable infrared dryer includes a fixed machine base 1, on which a barrel 3 is rotatably mounted, and an upstream end of the barrel 3 is provided with a feeding port, and the fixed machine base 1 is equipped with a feeding device 5, which includes a feeding hopper and a screw feeder, which facilitates the feeding of fruits and vegetables. Of course, the feeding device 5 can also be automatically fed in the form of a chute. , the downstream end of the barrel 3 is provided with a discharge port, the fixed base 1 is provided with a discharge hopper 9 connected with the discharge port, the barrel 3 is provided with a spiral stirring blade 37, the material The cartridge 3 is driven by a rotary power unit.

[0031] In this example, if figure 1 , 2 , 4, 5, 6, and 7, a pair of upstream support rollers 11 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com