Checking platform of breather valve

A technology of breathing valve and calibration platform, which is applied in the testing of measuring devices, instruments, and mechanical components, etc., to achieve the effects of stable testing performance, easy operation and maintenance, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

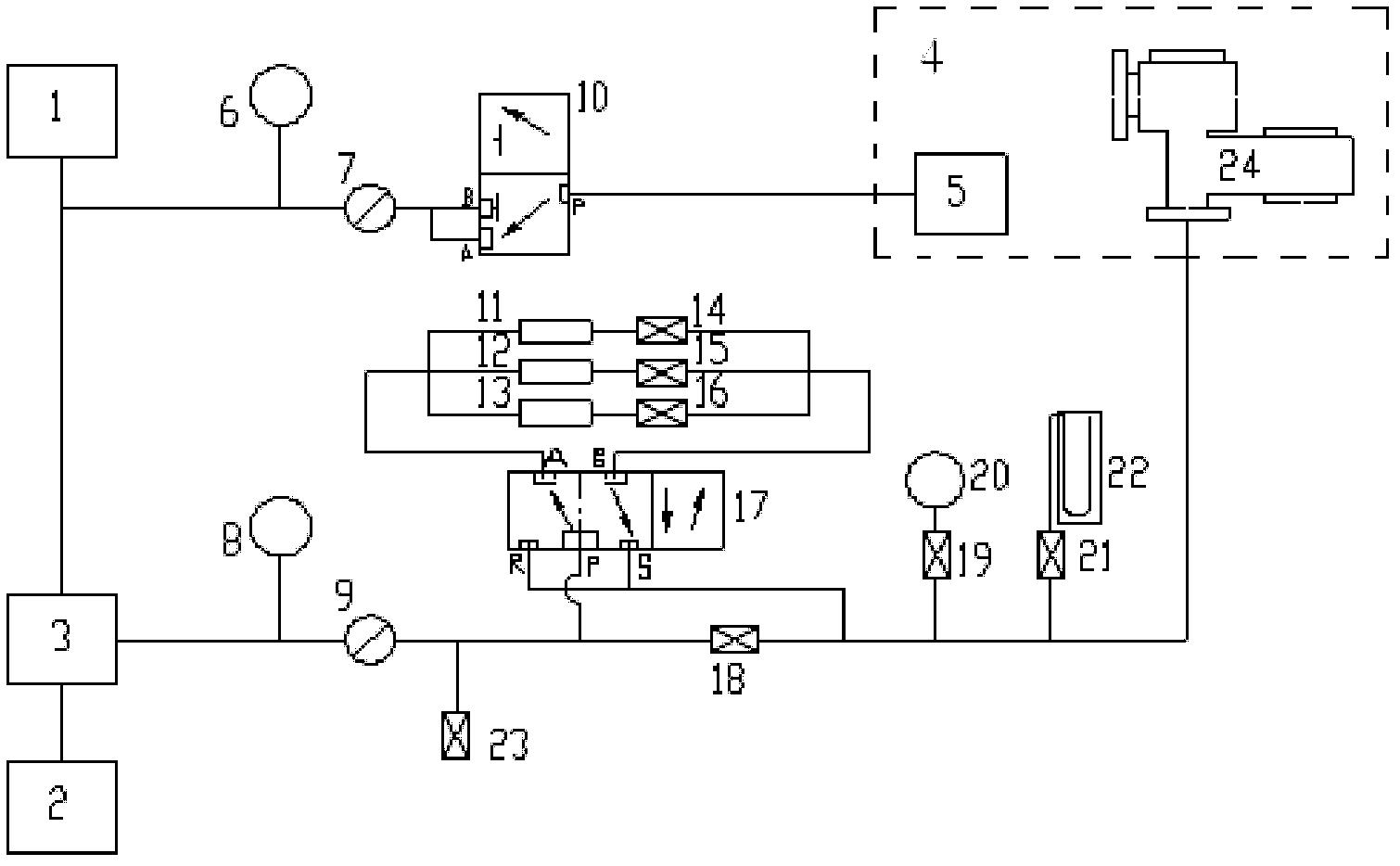

[0025] Such as figure 1 As shown, the breathing valve calibration platform of the present invention includes a calibration console and a card loading platform 4;

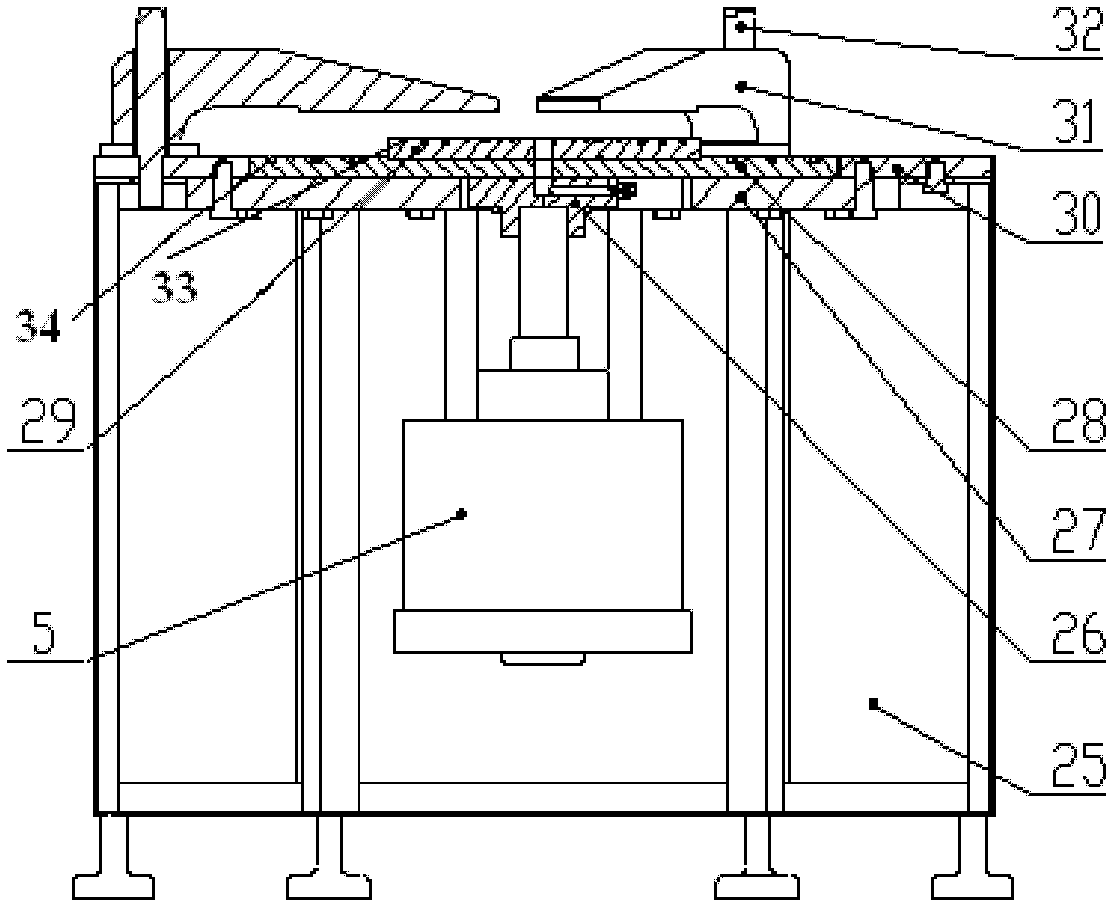

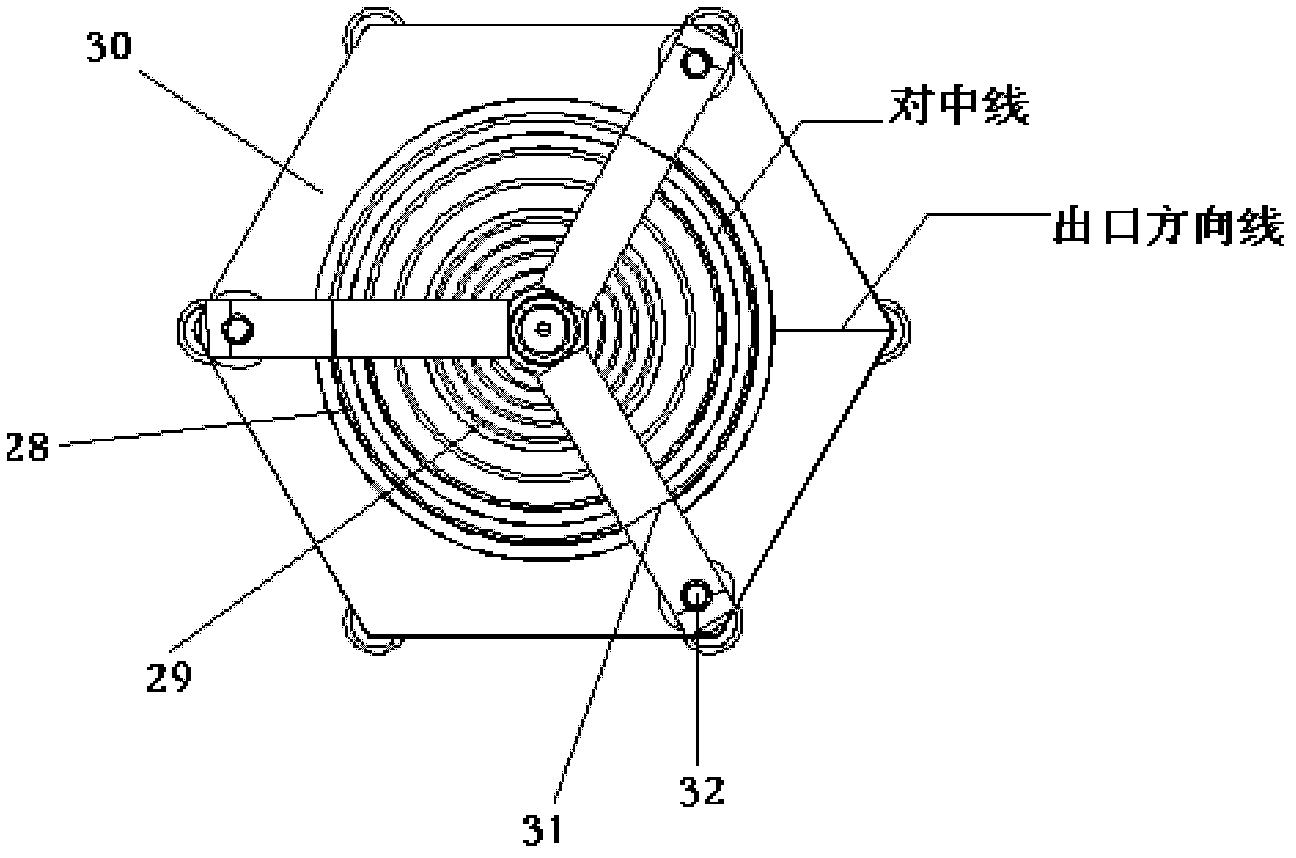

[0026] The breathing valve 24 to be checked is installed on the card loading platform 4; as figure 2 with image 3 As shown, the card loading platform 4 includes a hexagonal cabinet 25, a tray 26, a cylinder connecting plate 27, a large sealing plate 28, a small sealing plate 29, a table top 30, claws 31, claw rods 32, sealing ring group A33, sealing Ring group B34 and cylinder 5; the upper end of the hexagonal cabinet 25 is provided with a table 30, the outer edge of the table 30 matches the outer edge of the hexagonal cabinet, and the center of the table 30 has a circular through hole; the lower side of the table 30 Be connected with cylinder connecting plate 27 by bolt, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com