X-ray meter control system for printed circuit board (PCB) production

A PCB board and control system technology, which is applied in the field of X-ray detector control system for PCB board production, can solve the problems of missed detection and false detection, and achieve the effects of not easy failure, good use effect and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

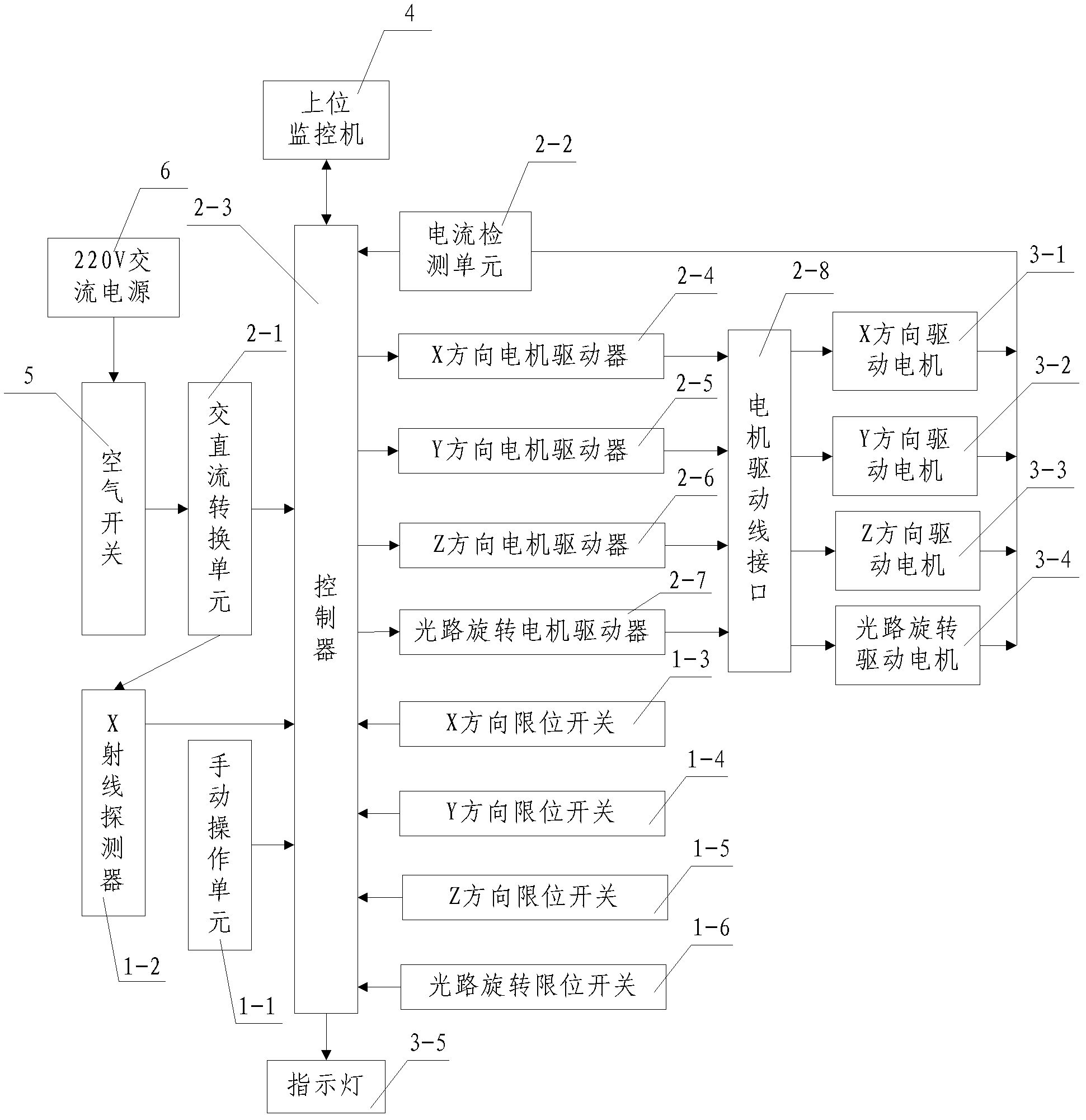

[0030] Such as figure 1 As shown, the present invention includes an upper monitoring machine 4, a lower computer control unit connected with the upper monitoring machine 4, and an input unit and an actuator unit connected with the lower computer control unit, and the lower computer control unit is integrated in a control box Inside; the actuator unit includes an X-direction drive motor 3-1 for driving the stage to move three-dimensionally, a Y-direction drive motor 3-2, a Z-direction drive motor 3-3, and an optical path rotation drive for driving the optical path to rotate Drive motor 3-4 and indicator light 3-5 for indicating the operating state of the stage; the input unit includes a manual operation unit 1-1, an X-ray detector for converting incident X-ray radiation beams into electrical signals Device 1-2 and X-direction limit switches for detecting the movement of the X-direction drive motor 3-1, Y-direction drive motor 3-2, Z-direction drive motor 3-3 and optical path ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com