Motor control apparatus

A technology of motor control and feedback control, applied in motor control, AC motor control, electrical program control, etc., can solve problems such as inability to perform open-loop control operations and inability to set reference positions for open-loop control operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

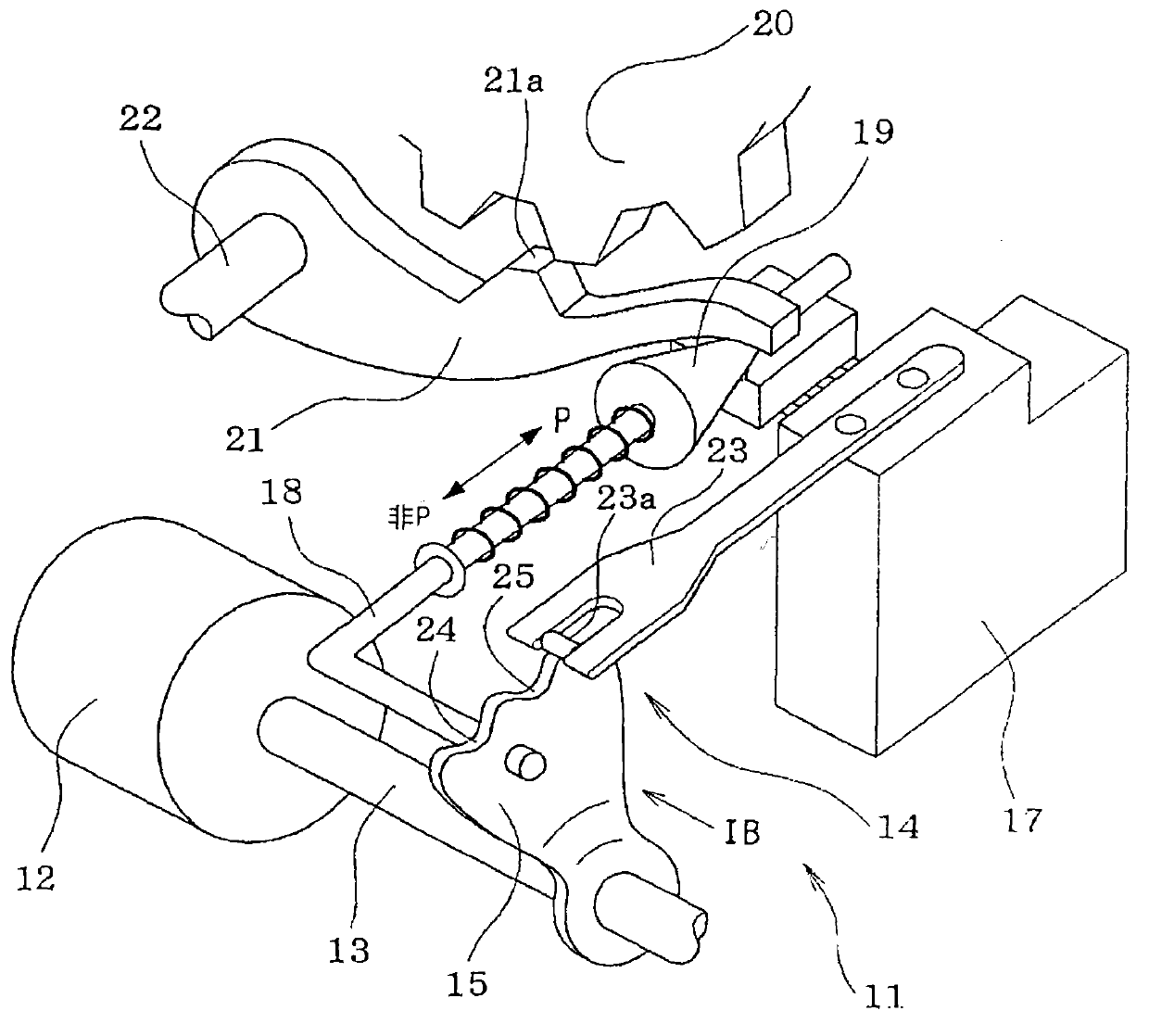

[0024] A gear shift device of an automatic transmission according to an embodiment of the present disclosure will be described.

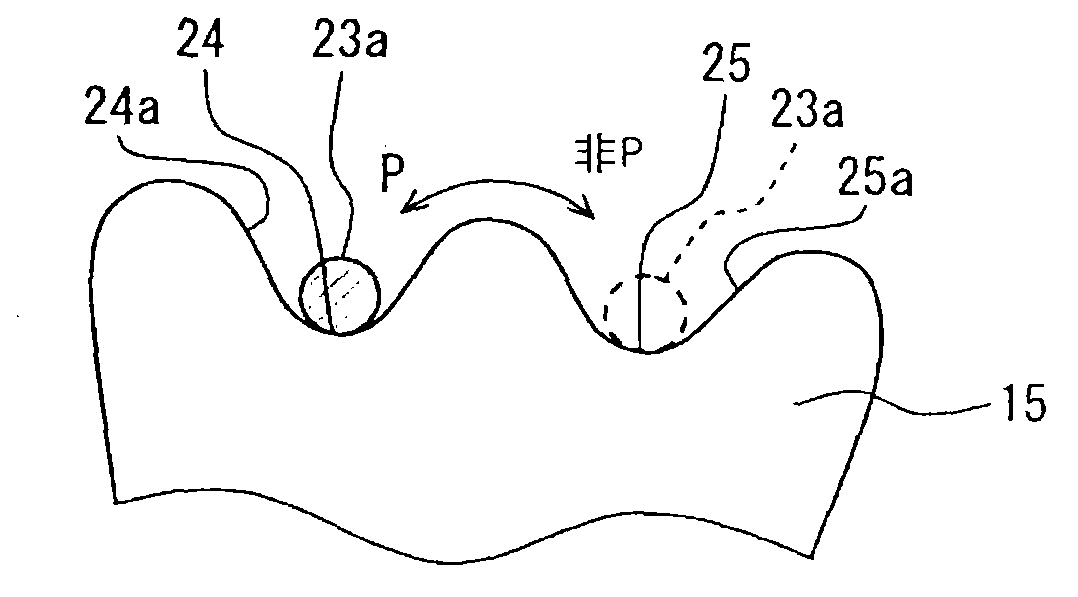

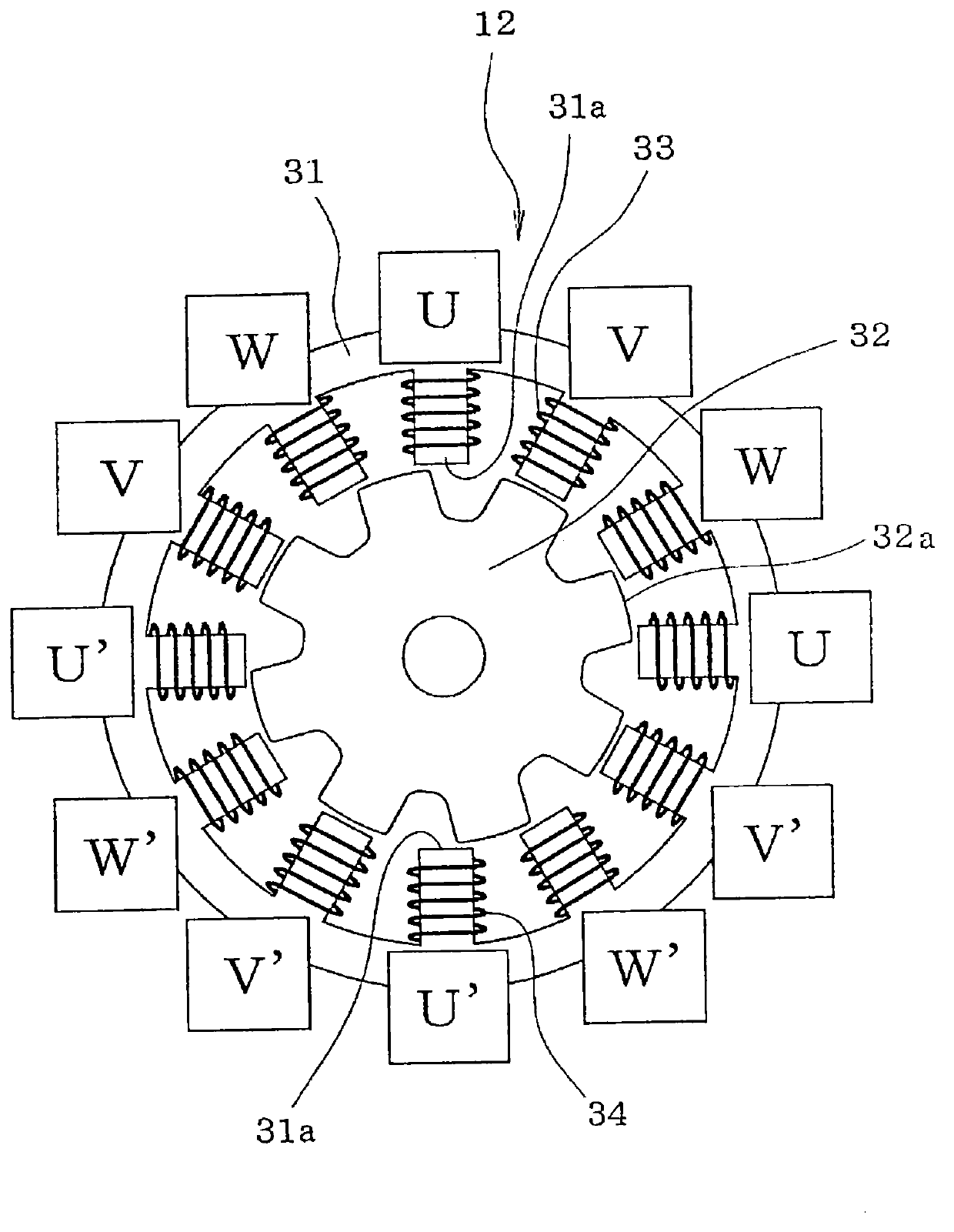

[0025] First, refer to Figure 1A and 1B The structure of the gear shift mechanism 11 is schematically described. The motor 12 serving as the drive source of the range switching mechanism 11 may be, for example, a switched reluctance (SR) motor. The motor 12 includes a speed reduction mechanism 26 that reduces the rotational speed of the rotor 32 of the motor 12 (see Figure 4 ). A brake 15 is fixed to the output shaft 13 of the motor 12 .

[0026] A parking lever 18 configured in an L shape is fixed to the stopper 15 . A cone 19 provided at a distal end portion of the parking lever 18 is in contact with the lock 21 . The locker 21 rotates upward or downward around the shaft 22 according to the operating position of the cone 19 to lock or unlock the parking gear 20 . The parking gear 20 is supplied to an output shaft of an automatic transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com