Automatic unloading and online detecting method for crude tobacco bales

A detection method and technology of cigarette packs, applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problems of low efficiency, large weight error, poor sampling representativeness, etc., and achieve high efficiency, high degree of automation, and comprehensive detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be further described in detail below.

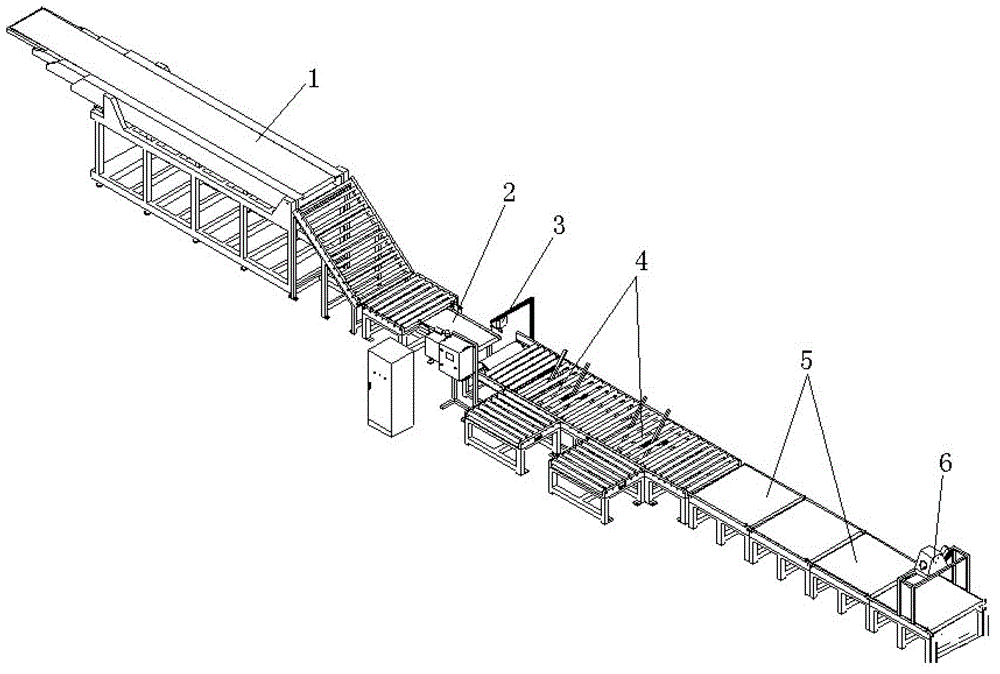

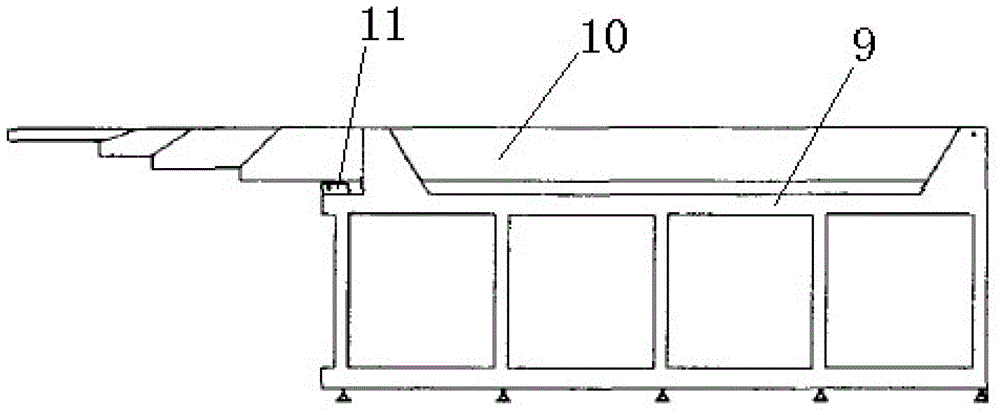

[0024] The automatic unloading and on-line detection method of the original cigarette pack of the present invention, its preferred specific implementation is as follows figure 1 Shown (packing machine and cigarette packet re-sorting device figure 1 Not shown in detail):

[0025] Include steps:

[0026] First, unload the cigarette packs through the telescopic unloading slide;

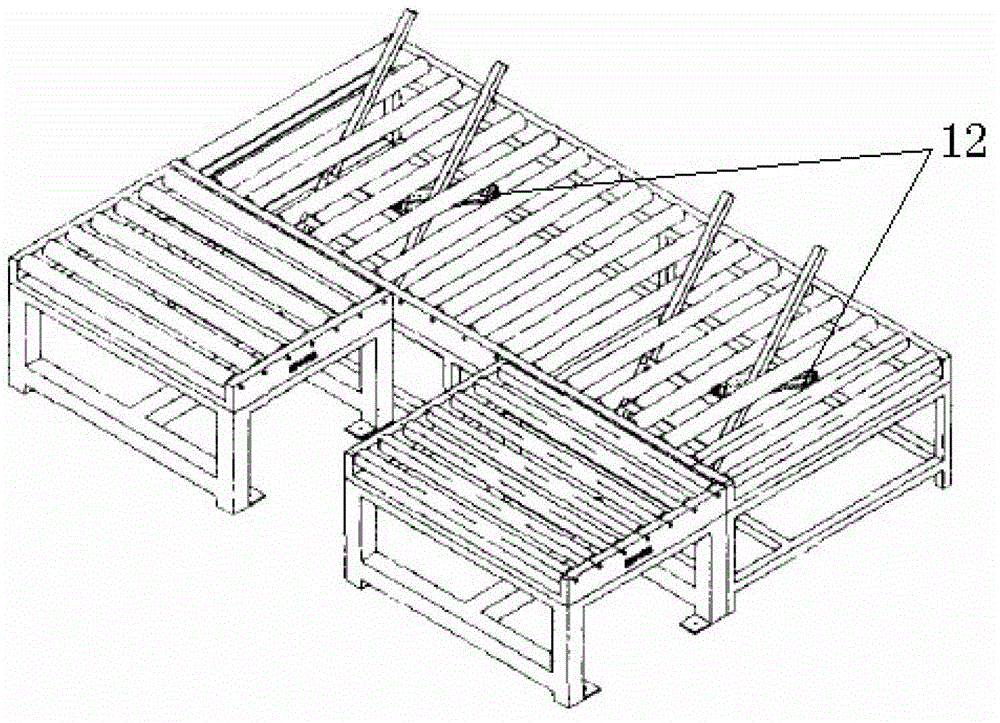

[0027] Then, carry out weight detection and moisture detection on the cigarette bales through the online belt scale and microwave moisture meter, and sort out the cigarette bales with qualified weight and moisture content through the cigarette bale sorting device;

[0028] Afterwards, unpack the cigarette bales with qualified weight and moisture content, test the chemical composition through the online near-infrared spectrometer, and then repack them. package classification;

[0029] Finally, the cigarette p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com