Union melt welding machine-dedicated device for longitudinal seams of cylindrical membrane walls

A technology of submerged arc automatic welding machine and cylindrical membrane wall, applied in arc welding equipment, welding equipment, manufacturing tools and other directions, can solve the problems of unstable walking and unsatisfactory welding effect, and achieve good welding effect and trolley walking. Stable and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

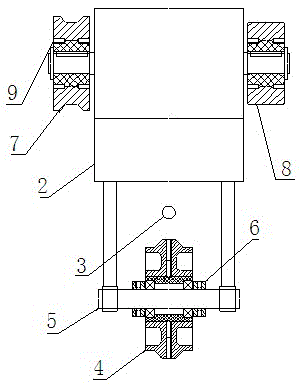

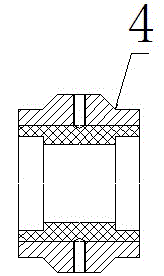

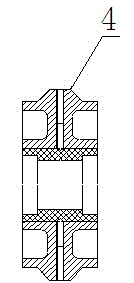

[0023] Such as figure 1 , 2 , 5, and 7, a special device for submerged arc automatic welding of the outer longitudinal seam welding of a cylindrical membrane wall, including a cylindrical membrane wall 1 and a cylindrical membrane installed on the outer longitudinal seam welding tool of the cylindrical membrane wall Type wall external longitudinal seam welding submerged arc automatic welding walking trolley, the walking trolley includes car body 2, guide wheel shaft 5 installed on the front fork of the car body, convex guide wheel 4 installed on the guide wheel shaft and limited by stop ring 6 , the driving shaft installed on the car body, the concave driving guide wheel 7 and the driving wheel 8 installed on the driving shaft through the key and the welding wire guide wire nozzle 3 installed on the vehicle body, the welding wire guide wire nozzle and the convex surface guide The wheels are located in the same pipe groove, and the center lines of the two in the traveling dire...

Embodiment 2

[0027] Such as image 3 , 4 , Shown in 6 and 7, a special device for submerged arc automatic welding of the internal longitudinal seam welding of a cylindrical membrane type wall. The difference from the first embodiment is that the device performs longitudinal seam welding inside the cylindrical membrane type wall, and the cylindrical membrane type wall The type wall is arranged on the inner longitudinal seam welding tool of the cylindrical membrane type wall, and the size of the convex part of the convex guide wheel is the same as that of two adjacent cylindrical membrane type walls to be welded on the inner longitudinal seam welding tool of the cylindrical membrane type wall. The size of the gap between them is equivalent, and the walking trolley matches the cylindrical membrane wall to be welded on the tooling.

[0028] The overall arc of the cylindrical membrane wall on the internal welding tooling of the cylindrical membrane wall is concave, and the overall arc of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com