Substation type precision compensation for robot system with additional external shaft

A robot system and precision compensation technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high precision requirements for manufacturing, assembly and installation, increase the cost of robot systems, and the uncertainty of system accuracy. Measuring the workload, the calculation process is simple and fast, and the effect of improving work adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

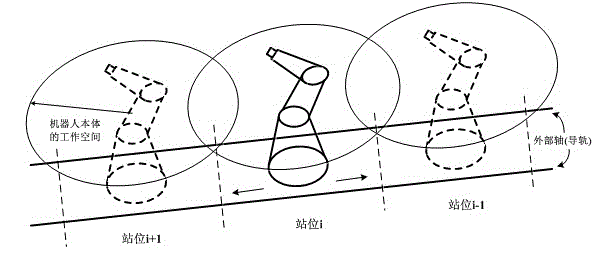

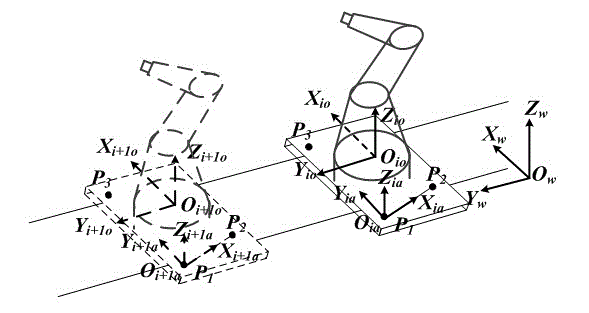

[0027] Such as figure 1 , 2 As shown, the steps of the sub-station accuracy compensation method for the robot system with additional external axes in the present invention are as follows:

[0028] Step 1: Establish a world coordinate system, and on this basis divide the guide rail into N substations.

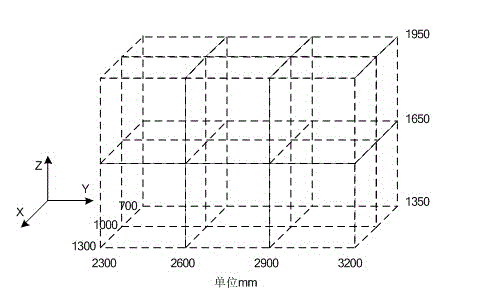

[0029] The method of using the laser tracker to establish the world coordinate system is: select 3 fixed points in the robot processing system space, measure the positions of the 3 points with the laser tracker, and set one point as the origin (named P w0 ), the other point is a point on the X axis (named P w1 ), the other point is a point on the XY plane (named P w2 ). by is the X-axis of the world coordinate system, with is the temporary Y-axis, according to the right-hand rule, cross-multiply the temporary Y-axis with the X-axis to get the Z-axis of the world coordinate system, and then use the Z-axis of the world coordinate system to cross-multiply the X-axis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com