Walkable 40 type concrete batching plant

A mixing plant and concrete technology, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve problems such as troubles, and achieve the effects of avoiding spillage, fast production investment, and convenient and quick use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

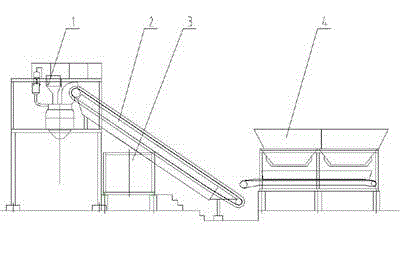

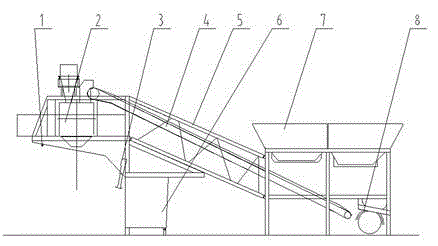

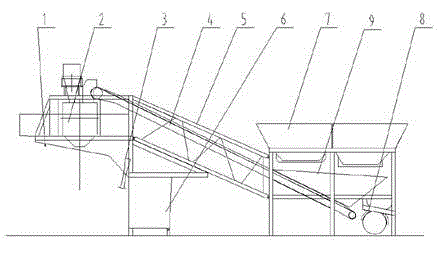

[0016] Embodiment 1, a kind of walkable 40 type concrete batching plant, refer to figure 2 , on the basis of the conventional mixing main building 2, belt conveyor 4, operating room 6 and batching system 7, the belt conveyor 4 extends to the bottom of the batching system 7 to integrate weighing and conveying functions, and the connecting body 5 connects the mixing main building 2 and the batching system 7. The batching system 7, the batching system 7 is provided with wheels 8, the telescopic outrigger 3 is fixed on the lower part of the mixing main building 2, and the traction pin 1 is fixed on the front part, and the whole structure is connected into a rigid whole, which constitutes a structure of the present invention .

Embodiment 2

[0017] Embodiment 2, a kind of walkable 40 type concrete batching plant, refer to image 3 , Figure 4 , on the basis of Embodiment 1, the operating room 6 rotating shaft is installed on the frame, the tail and both sides of the belt conveyor 4 below the batching system 7 are provided with baffles 9, and the powder metering bin of the batching system 7 is installed on the rotating shaft On the frame, others are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com