Ink cartridge for ink jet printer

A technology of inkjet printers and ink cartridges, which is applied in printing and other fields, can solve problems such as unfavorable inkjet printer production costs, affecting printing quality, ink deposition, etc., to improve ink deposition and fluidity instability, and improve stability and fluency , reduce the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

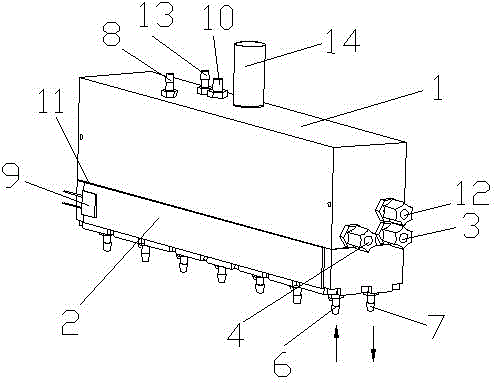

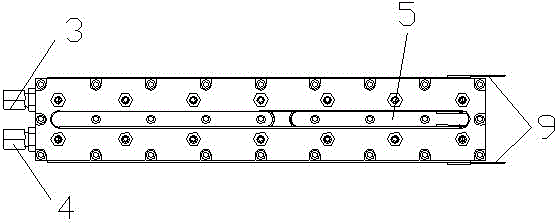

[0019] like figure 1 and figure 2 As shown, the inkjet printer ink cartridge includes an upper box 1 and a lower box 2, and the upper box 1 and the lower box 2 are closely connected; the upper box 2 includes a positive pressure chamber and a negative pressure chamber, and the positive and negative pressure chambers are not connected. The positive pressure chamber is provided with an ink inlet 3, the negative pressure chamber is provided with an ink outlet 4, and the lower box is provided with a groove 5 and no less than 5 pairs of nozzle inlets 6 and nozzle outlets 7 that are installed in conjunction with the nozzles. The groove 5 separates the nozzle inlet 6 from the nozzle outlet 7: the ink enters the nozzle from the positive pressur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap