Air resistance-reduced ship with front propelling plant and skeg course control system

A course control and skeg technology, applied in propulsion components, ship propulsion, rudder steering with propulsion components, etc., can solve problems such as steering offset thrust, poor turning performance, and difficulty in course control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below based on the drawings.

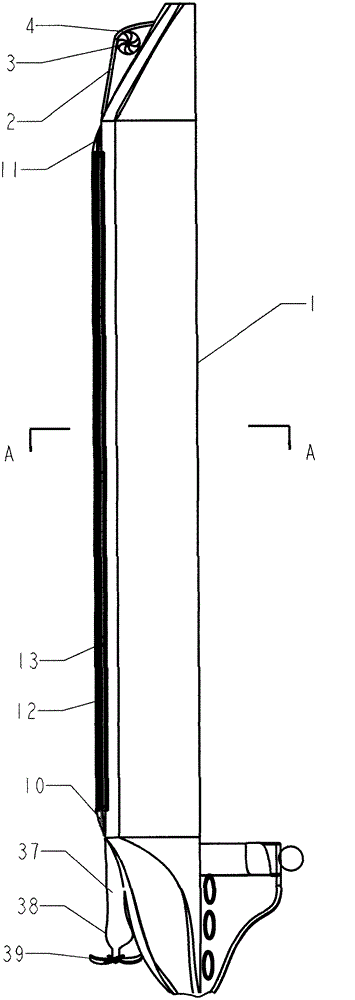

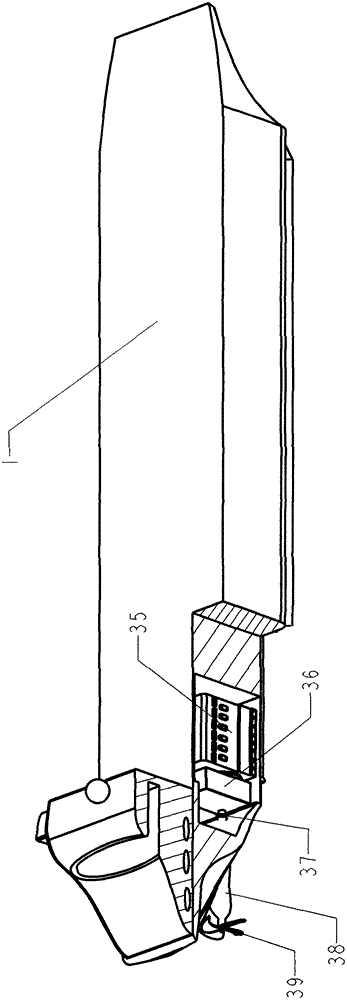

[0038] Such as figure 1 and Figure 5 As shown, the motor 3 installed in the skeg 2 drives the propeller 4 to rotate, and the crew operates the steering handle 5 of the cab or two wings, and adjusts the speed of the motor 3 through the control cabinet 6 and the electric or hydraulic system 7 .

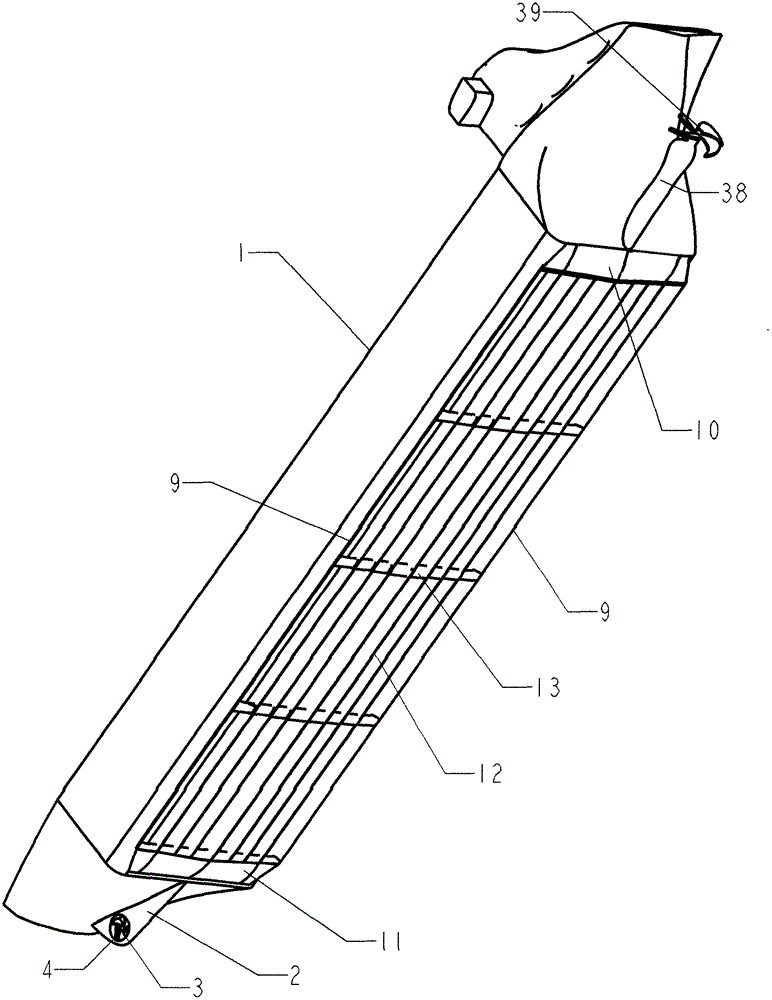

[0039] Such as figure 1 , figure 2 and Figure 4 As shown, part of the bottom of the ship is used as the nest bottom 8, and the adjacent keel 9, the bow streamlined protrusion 10 and the stern streamlined protrusion 11 form a closed periphery, which forms a nest structure with the nest bottom 8. The opening of the nest structure is downwards. The interior of the nest is separated into multiple closed areas by a plurality of longitudinal sealing plates 12, and the longitudinal sealing plates 12 of different heights are arranged from the middle to both sides. The longitudinal closed area i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com