A double-wing type deep-water cage suitable for single-point mooring

A technology of single-point mooring and deep-water cages, which is applied in application, climate change adaptation, fish farming, etc., can solve problems that restrict the development of deep-water cages, and achieve enhanced frontal stability, wave resistance, and high rigidity , the effect of enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

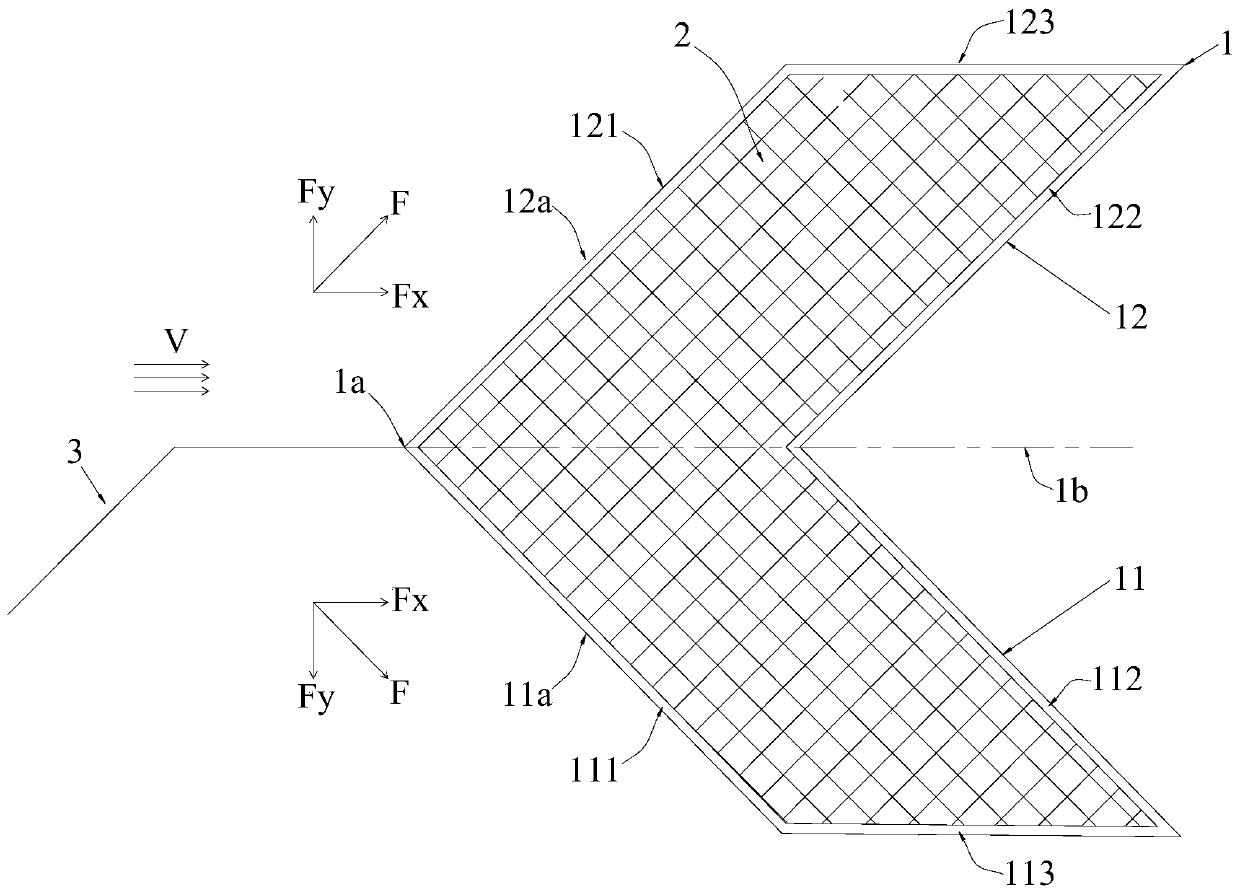

[0045] like figure 2 As shown, the first embodiment of the present invention is based on the above-mentioned inventive concepts, and adopts the following specific schemes for the frame system 1:

[0046] Frame system 1 is also provided with front frame edge 14 and rear frame edge 15; left wing frame part 11 is made up of left wing front side frame edge 111, left wing rear side frame edge 112 and left wing outer frame edge 113, and left wing front side frame edge 111 is The front edge 11a of the left wing frame member 11, the left outer side frame edge 113 is connected between the outer end of the left wing front side frame edge 111 and the outer end of the left wing rear side frame edge 112, and the left wing front side frame edge 111, the left wing rear side frame The side 112 and the left-wing outer frame edge 113 are arranged in a parallelogram, that is, the left-wing front side frame edge 111 is parallel to the left-wing rear side frame edge 112; frame edge 123, the righ...

Embodiment 2

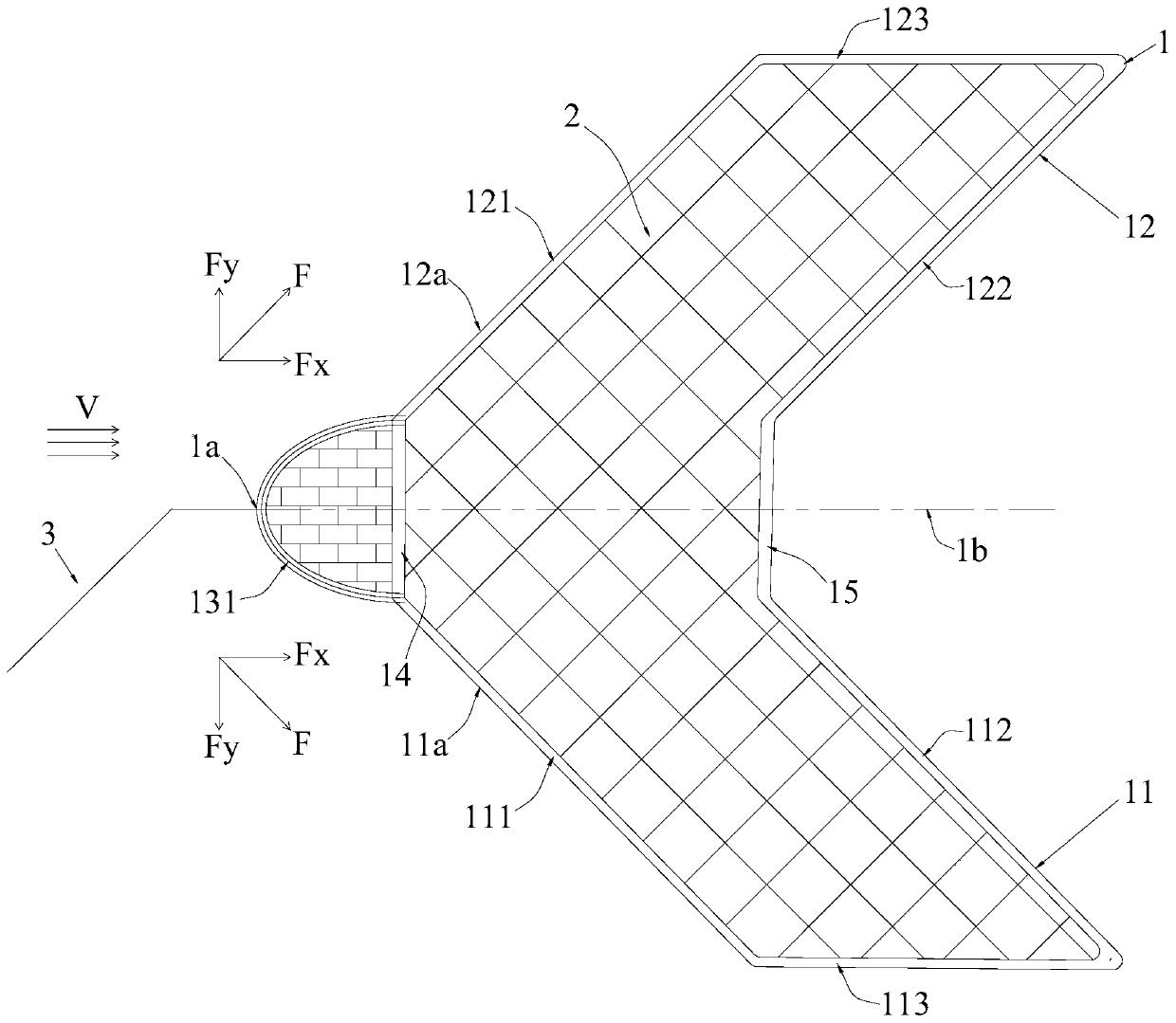

[0048] like image 3 and Figure 4 As shown, the second embodiment of the present invention is based on the above-mentioned inventive concepts, and adopts the following specific schemes for the frame system 1:

[0049]The frame system 1 is also provided with a main frame 13, which is a closed frame composed of an elliptical arc front frame 131, a left frame edge 132, a right frame edge 133 and a semicircular arc rear frame 134, wherein the ellipse The arc-shaped front frame 131 protrudes forward, the semi-circular arc-shaped rear frame 134 protrudes backward, and the left frame edge 132 is connected between the left end of the elliptical arc-shaped front frame 131 and the left end of the semi-circular arc-shaped rear frame 134 , the right frame edge 133 is connected between the right end of the elliptical arc-shaped front frame member 131 and the right end of the semicircular arc-shaped rear frame member 134; At the middle position of the right frame edge 133 . Thereby, by ...

Embodiment 3

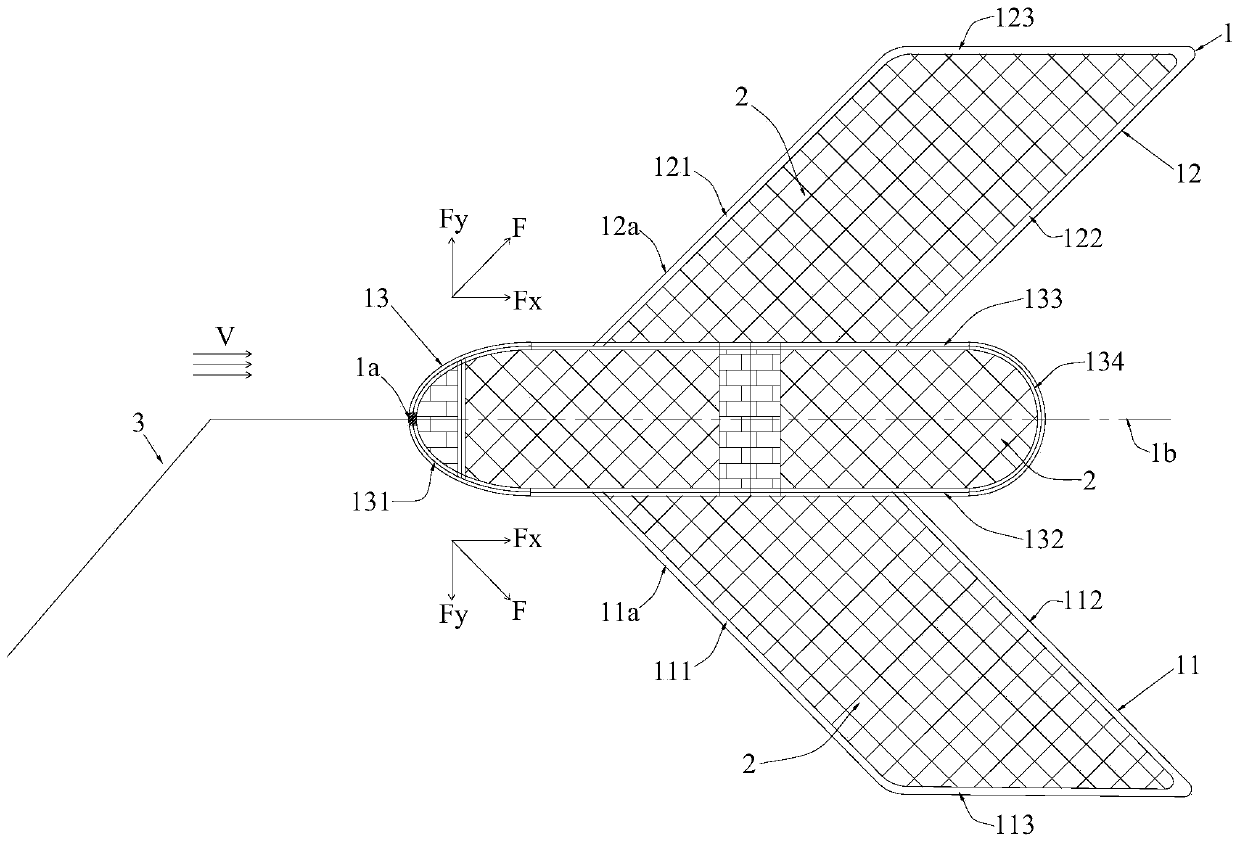

[0053] like Figure 5 As shown, the third embodiment of the present invention is based on the above-mentioned inventive concepts, and adopts the following specific schemes for the frame system 1:

[0054] The frame system 1 of the third embodiment is basically the same as that of the second embodiment, and their difference is that in the third embodiment, according to the direction from the front end to the rear end of the frame system 1, the left frame side 132 and the right frame side 133 are all from the frame The outer side of the system 1 extends obliquely toward the inner side; thus, the water resistance experienced by the frame system 1 along the direction of the axis of symmetry 1 b can be further reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com