Method for preparing SD-3 demulsifier

A demulsifier, SD-2 technology, applied in the field of preparation of SD-3 demulsifier, can solve the problems of inability to adapt to demulsifier dehydration treatment, environmental pollution, poor biodegradability of demulsifier, etc., and reduce the cost of demulsification and dehydration. , the effect of reducing environmental pollution and saving heating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

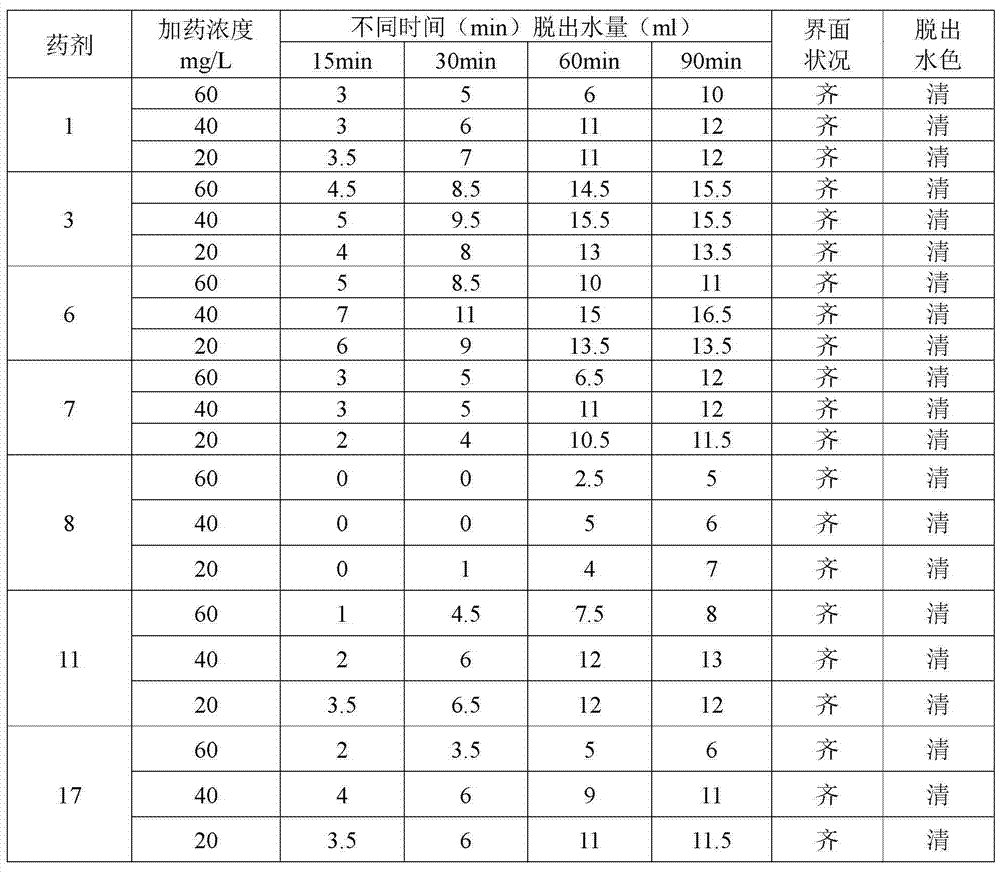

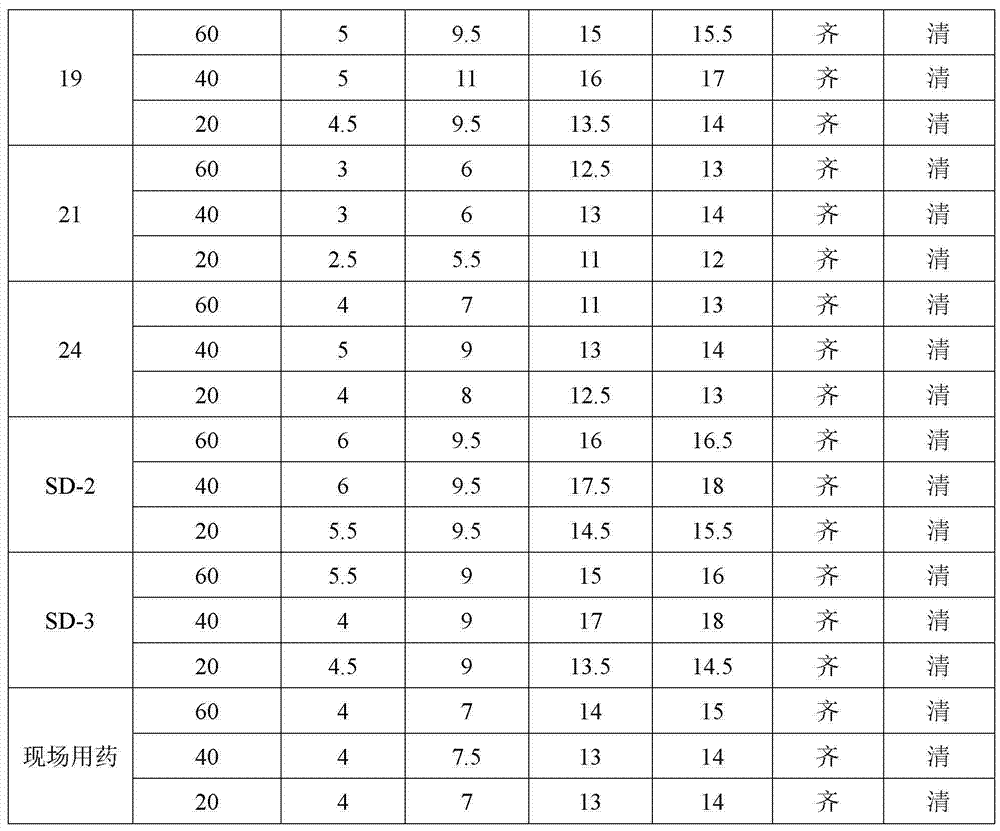

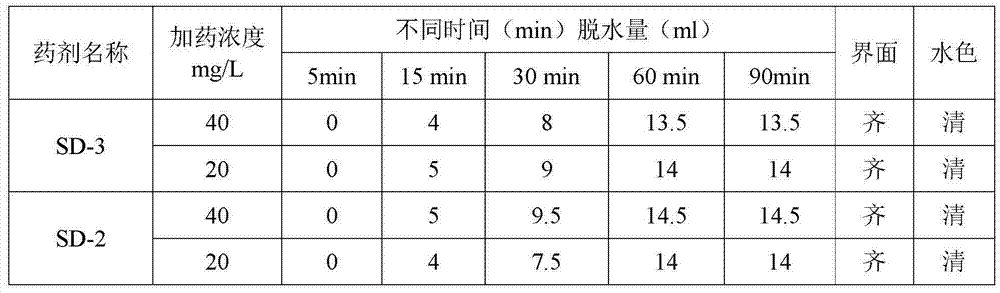

Examples

Embodiment 1

[0021] Will C 4-9 Organic phenol and diethylenetriamine are mixed in a molar ratio of 1:2, heated and controlled at 30°C, stirred for 30 minutes, and the molar ratio is C 4-9 Organic phenol: formaldehyde is added dropwise with formaldehyde in the ratio of 1:2. After the dropwise addition, the temperature is raised to 150-170°C, and the temperature is controlled to react for 3 hours. The product is a new type of thermoplastic resin initiator.

[0022] Add the catalyst sodium hydroxide to the thermoplastic resin, stir while heating, heat to 90°C, turn on the vacuum pump for 30 minutes, control the temperature at 115-135°C, add propylene oxide and ethylene oxide continuously respectively, and the feeding is completed Finally, react at a temperature of 115-135°C and a pressure of 0.1-0.3Mpa for 30 minutes, lower the temperature to 90°C, and turn on the vacuum pump for 30 minutes to obtain polyether.

[0023] The amount added is 1:50:25 according to the weight ratio of thermoplast...

Embodiment 2

[0027] Will C 4-9 Organic phenol and triethylenetetramine are mixed in a molar ratio of 1:3, heated and controlled at 30-40°C, stirred for 30 minutes, and the molar ratio is C 4-9 Formaldehyde is added dropwise at a ratio of 1:3 of organic phenol: formaldehyde. After the dropwise addition, the temperature is raised to 150-170°C, and the temperature is controlled to react for 3 hours. The product is a new type of thermoplastic resin initiator.

[0028] Add the catalyst potassium hydroxide to the thermoplastic resin, stir while heating, heat to 90°C, turn on the vacuum pump for vacuum treatment for 30 minutes, control the temperature at 115-135°C, add propylene oxide and ethylene oxide continuously respectively, and the feeding is completed Finally, react at a temperature of 115-135°C and a pressure of 0.1-0.3Mpa for 30 minutes, lower the temperature to 90°C, and turn on the vacuum pump for 30 minutes to obtain polyether.

[0029] The amount added is 1:100:100 according to the ...

Embodiment 3

[0033] Will C 4-9 Organic phenol and tetraethylenepentamine are mixed in a molar ratio of 1:4, heated and controlled at 30-40°C, stirred for 30 minutes, and the molar ratio is C 4-9 Organic phenol: formaldehyde is added dropwise with formaldehyde in the ratio of 1:4. After the dropwise addition, the temperature is raised to 150-170°C, and the temperature is controlled for 3 hours to react. The product is a new type of thermoplastic resin initiator.

[0034] Add the catalyst boron trifluoride to the thermoplastic resin, stir while heating, heat to 90°C, turn on the vacuum pump for vacuum treatment for 30 minutes, control the temperature at 115-135°C, add propylene oxide and ethylene oxide continuously, and feed After completion, react at a temperature of 115-135°C and a pressure of 0.1-0.3Mpa for 30 minutes, lower the temperature to 90°C, and turn on the vacuum pump for 30 minutes to obtain polyether.

[0035] The amount added is 1:200:200 according to the weight ratio of ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com