Pulling-resistant bidirectional sliding friction bearing

A technology of sliding friction and bearing plate, which is applied in construction, bridge construction, bridges, etc., can solve the problems of limited horizontal displacement amplitude, no self-adaptability, poor durability, etc., and achieve large vertical bearing capacity, vibration reduction and isolation Clear mechanism and simple support structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

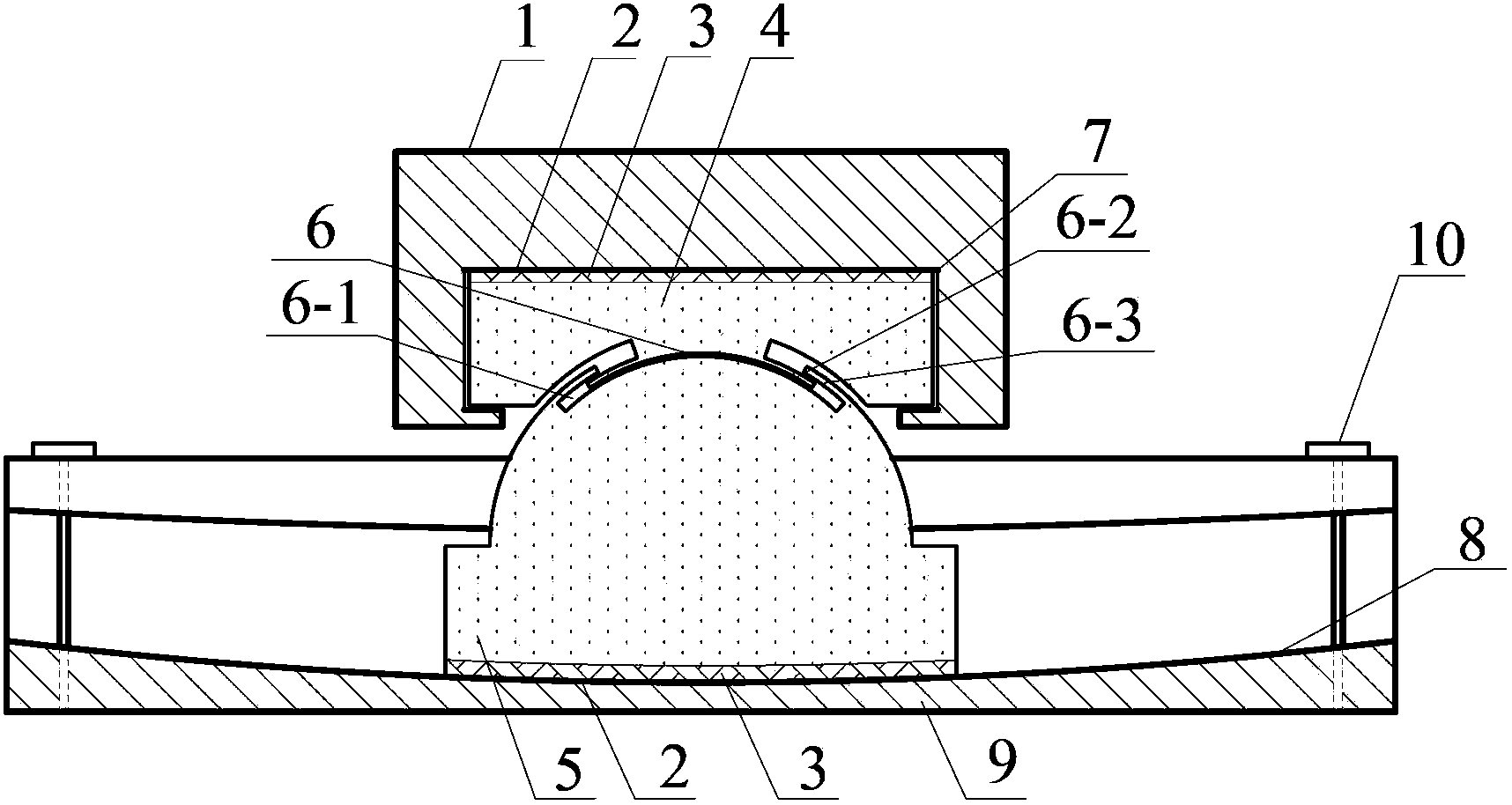

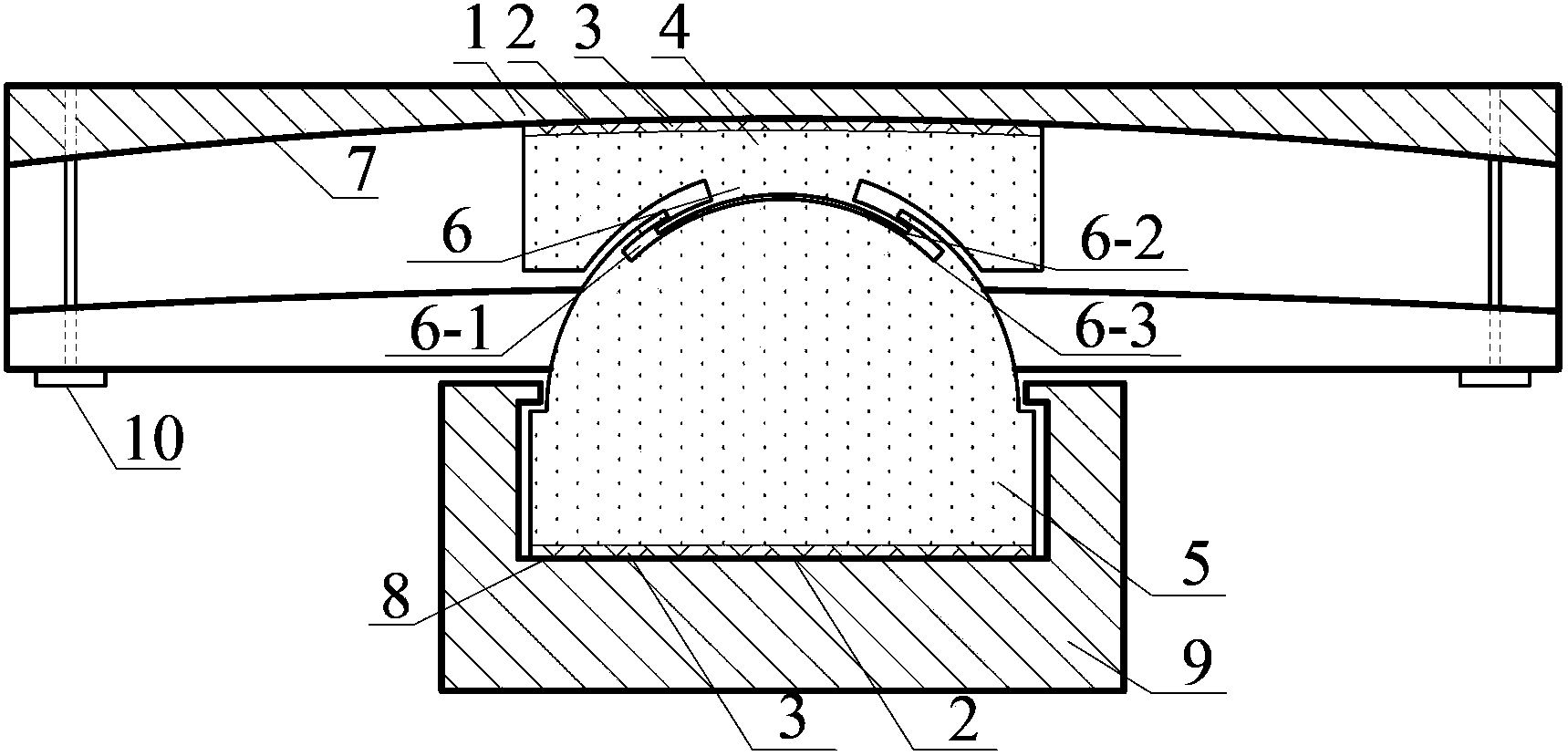

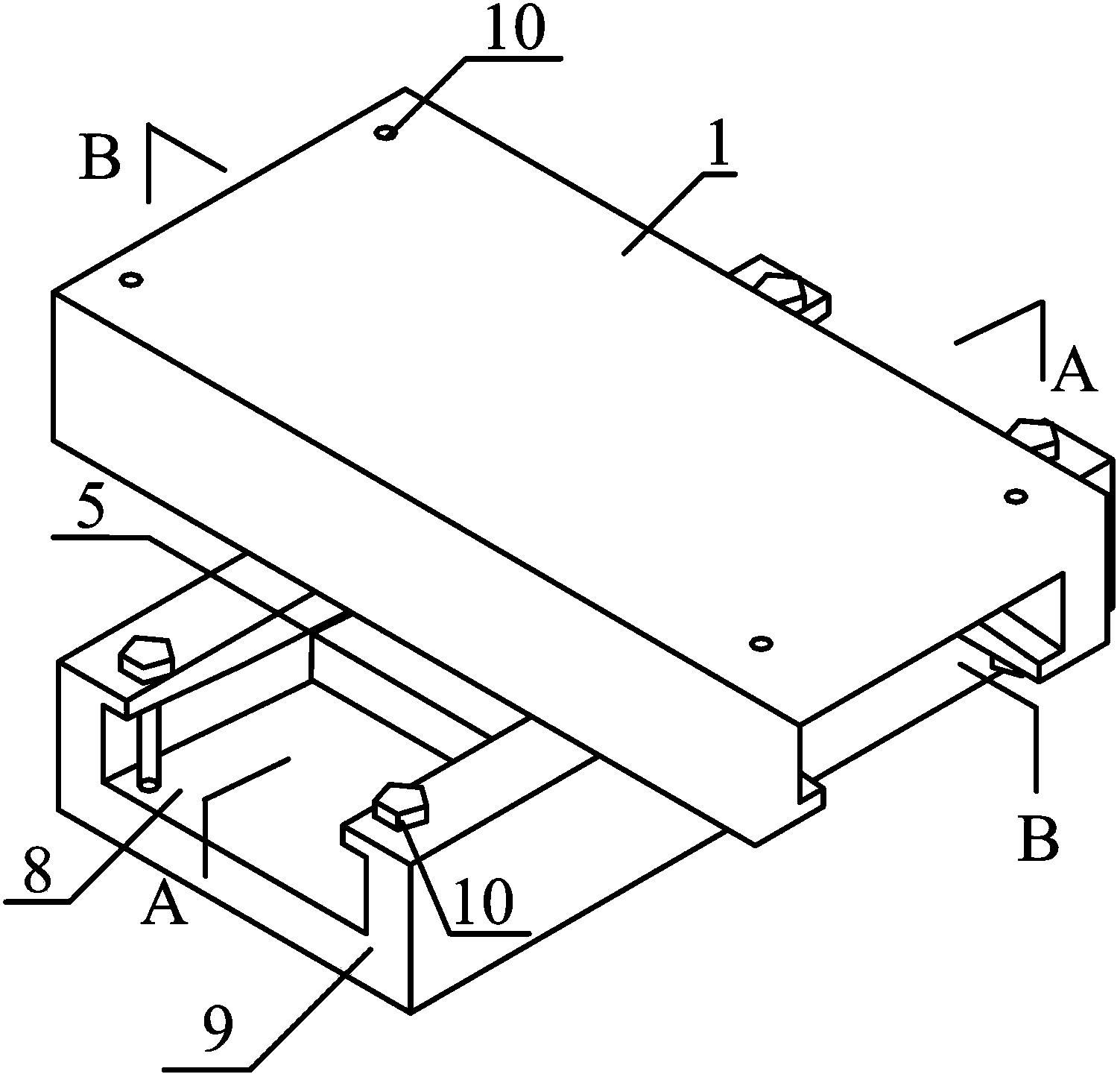

[0021] figure 1 It is a schematic diagram of the structure of the anti-pull bidirectional sliding friction bearing. Such as figure 1 As shown, the anti-pull bidirectional sliding friction support includes an upper seat plate 1, a concave spherical surface slider 4, a convex spherical surface lower slider 5, an anti-pull system 6, a lower support plate 9, and a limit anti-pull device 10. The upper support plate 1 and the lower support plate 9 have slideways. The upper support plate slide metal plate 2, the upper convex curved surface of the slider on the concave spherical surface is inlaid with the organic skateboard 3, the lower convex surface of the lower slide 5 on the convex spherical surface is inlaid with the organic slide plate 3, and the lower support plate slides the metal plate 2.

[0022] The organic skateboard 3 inlaid on the curved surface of the slider on the concave spherical surface and the curved metal plate 2 of the upper support plate have a relatively small coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com