Remote wired remote control explosion-proof crawler loader

A wired remote control, slag scraper technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of large dust, loose ore falling, poor air quality, etc. To achieve the effect of wide viewing angle, smooth and soft operation without shock, and stable monitoring image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

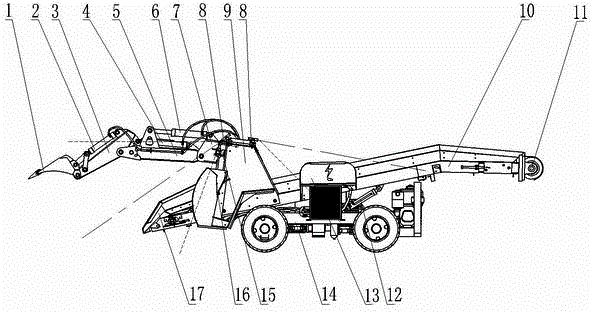

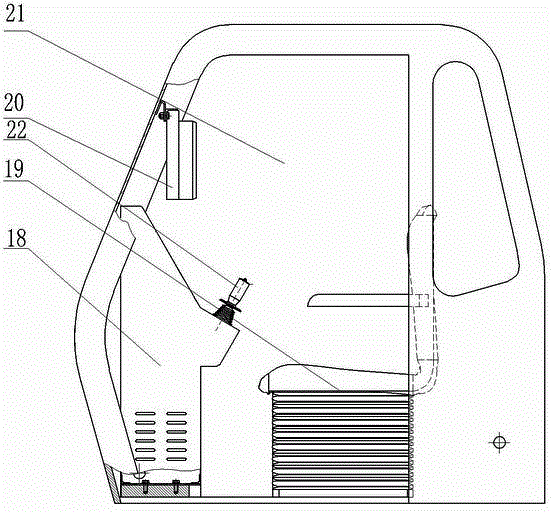

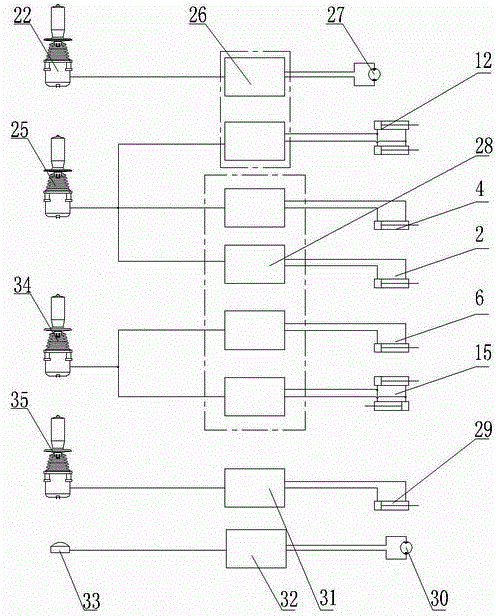

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention includes a control room 21, an electronic control cabinet 18, an electro-hydraulic proportional control system, a monitoring and display system, a hydraulic system and a mechanical system. The control room 21 is placed on the ground, and the control room 21 is connected to the slag removal machine through a shielded cable of more than 500 meters, which can provide a comfortable operating environment for the driver's operation. The electronic control cabinet 18 is installed in the control room 21. , 15-inch sub-monitor 20, driver's seat 19.

[0024] The electronic control cabinet 18 includes a single-axis electronic proportional control handle 1 35, a single-axis electronic proportional control handle 2 22, a cross electronic proportional control handle 1 25, a cross electronic proportional control handle 2 34, the back-end equipment of the monitoring display system and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com