Electronic type CNG (Compressed Natural Gas) gas charging station sequence control panel

A sequential control and gas filling station technology, applied in the field of CNG gas filling stations, can solve problems such as the inability to realize the priority supply of gas filling vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

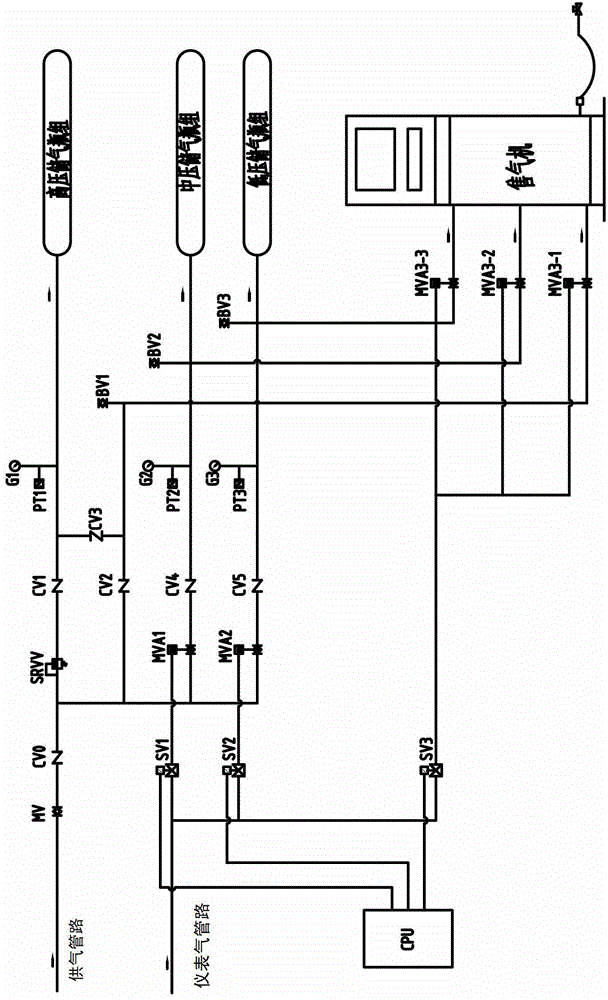

[0012] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, an electronic CNG filling station sequence control panel includes a gas supply pipeline, an instrument gas pipeline and a control unit. The high-pressure gas supply pipeline of the gas vending machine, the intake pipeline of the medium-pressure gas storage cylinder group, the medium-pressure gas supply pipeline of the gas vending machine, the intake pipeline of the low-pressure gas storage cylinder group, and the low-pressure gas supply pipeline of the gas vending machine; the main intake pipeline passes through in sequence The connected ball valve MV and one-way valve CV0 are respectively connected to the intake pipeline of the high-pressure gas storage cylinder group, the intake pipeline of the medium-pressure gas storage cylinder group, and the intake pipeline of the low-pressure gas storage cylinder group; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com