Full-liquid-phase fluid uniform distribution device of high-pressure wound-tube type heat exchanger

A coiled tube heat exchanger, high pressure technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of uneven distribution of fluid, and achieve the goal of improving heat transfer performance and heat transfer performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

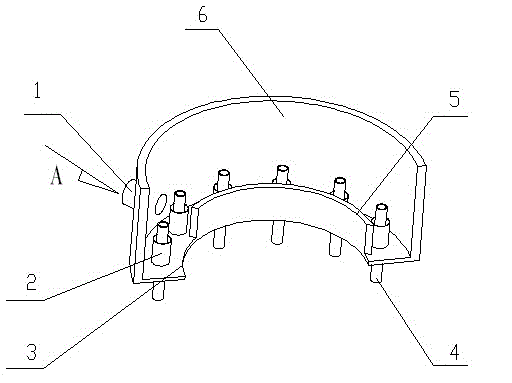

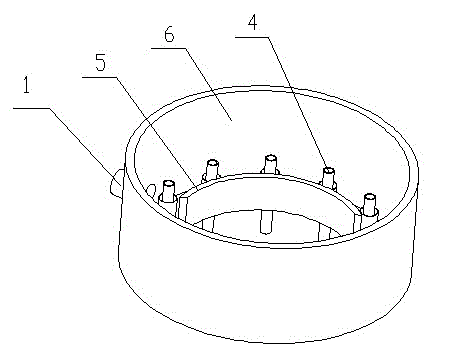

[0011] The all-liquid phase fluid uniform distribution device of the high-pressure wound tube heat exchanger includes a shell 6 and a central tube 5. The receiving plate is welded between the shell and the central tube. The shell above the receiving plate is provided with a connecting pipe 1. There are at least two vertically arranged heat exchange tubes 4 between the central tube and the shell. A shell side is formed between the shell and the heat exchange tubes. The liquid receiving plate is welded with a cofferdam tube sleeved on the heat exchange tubes. 2. The upper end of the cofferdam pipe is horizontal, and each cofferdam pipe is on a horizontal surface. The fluid enters the shell side after passing through the connecting pipe 1, passing through the annular gap bearing surface formed by the cofferdam tube and the outer wall of the heat exchange tube. The point A of the connection pipe 1 is the liquid inlet. The liquid is evenly distributed on the liquid receiving plate. ...

Embodiment 2

[0013] The all-liquid phase fluid uniform distribution device of the high-pressure wound tube heat exchanger includes a shell 6 and a central tube 5. The receiving plate is welded between the shell and the central tube. The shell above the receiving plate is provided with a connecting pipe 1. There are at least two vertically arranged heat exchange tubes 4 between the central tube and the shell. A shell side is formed between the shell and the heat exchange tubes. The liquid receiving plate is welded with a cofferdam tube sleeved on the heat exchange tubes. 2. The upper end of the cofferdam pipe is horizontal, and each cofferdam pipe is on a horizontal surface. The fluid enters the shell side after passing through the connecting pipe 1, passing through the annular gap bearing surface formed by the cofferdam tube and the outer wall of the heat exchange tube. The point A of the connection pipe 1 is the liquid inlet. The liquid is evenly distributed on the liquid receiving plate. ...

Embodiment 3

[0015] The all-liquid phase fluid uniform distribution device of the high-pressure wound tube heat exchanger includes a shell 6 and a central tube 5. The receiving plate is welded between the shell and the central tube. The shell above the receiving plate is provided with a connecting pipe 1. There are at least two vertically arranged heat exchange tubes 4 between the central tube and the shell. A shell side is formed between the shell and the heat exchange tubes. The liquid receiving plate is welded with a cofferdam tube sleeved on the heat exchange tubes. 2. The upper end of the cofferdam pipe is horizontal, and each cofferdam pipe is on a horizontal surface. The fluid enters the shell side after passing through the connecting pipe 1, passing through the annular gap bearing surface formed by the cofferdam tube and the outer wall of the heat exchange tube. The point A of the connection pipe 1 is the liquid inlet. The liquid is evenly distributed on the liquid receiving plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com