Photoelectric detector array-based glass shape detection system

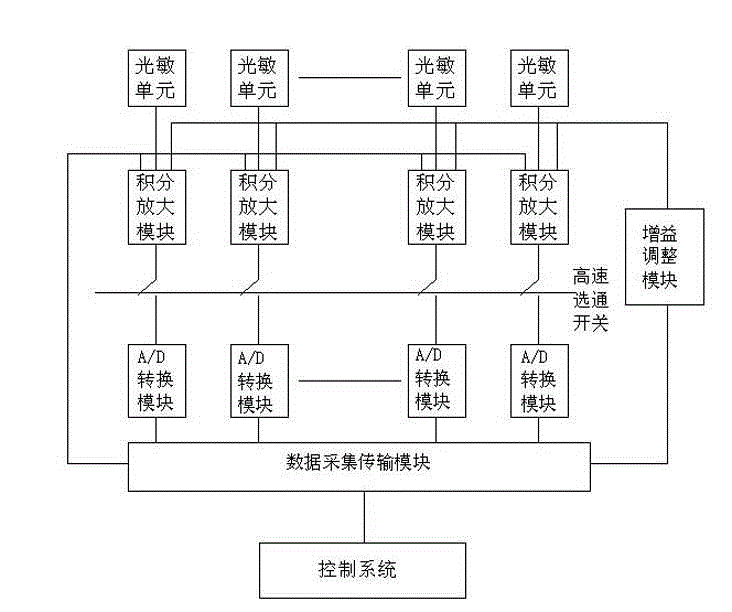

A photodetector and shape detection technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of data errors, inaccurate data, and easy to be affected by ambient light, and achieve high accuracy and high response frequency. , the effect of wide linear output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

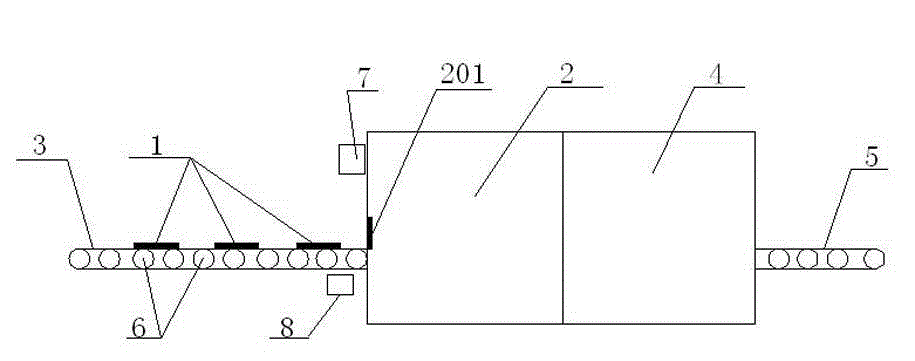

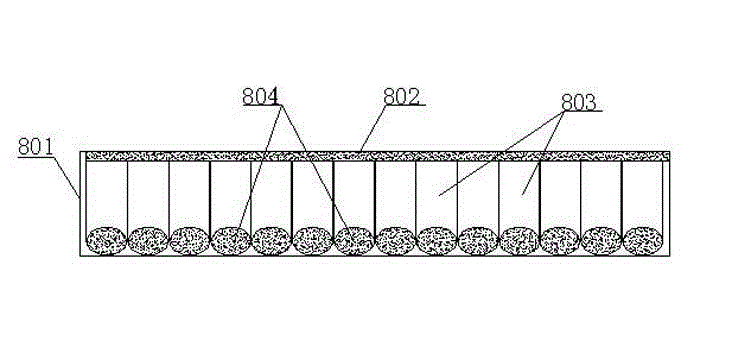

[0019] As shown in the figure, the glass shape detection device based on the photodetector array includes a heating furnace 2 for tempering glass, a loading table 3 arranged on both sides of the heating furnace 2, a tempering cooling section 4 and a loading table 5 1. The control system and light source 7 used to control the working process of the tempering furnace. A furnace door 201 is arranged on one side of the entrance of the heating furnace 2. A roller conveying mechanism 6 is respectively arranged on the loading table 3 and the unloading table 5. The roller conveying The mechanism 6 is provided with a plurality of roller tables, and the rotation of the roller tables drives the detected glass to move on the loading table 3 and the unloading table 5, and the output light of the light source 7 is irradiated on the detected glass. There is also a detector 8 for receiving light intensity distribution information under the bottom. The detector 8 includes a housing 801, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com