High temperature and high pressure drainage dynamic evaluation system for coal bed and gas reservoir double-layer commingled production

A high-temperature, high-pressure, double-layer combined mining technology, applied to measuring devices, instruments, etc., can solve problems such as mismatch between mine practice and theory, low utilization rate, low recovery rate, etc., and optimize the system of combined drainage and gas recovery , fast data recording and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0038] The 3# coal seam and 15# coal seam marked in this paper are the actual stratigraphic division names of the Qinshui Basin in my country.

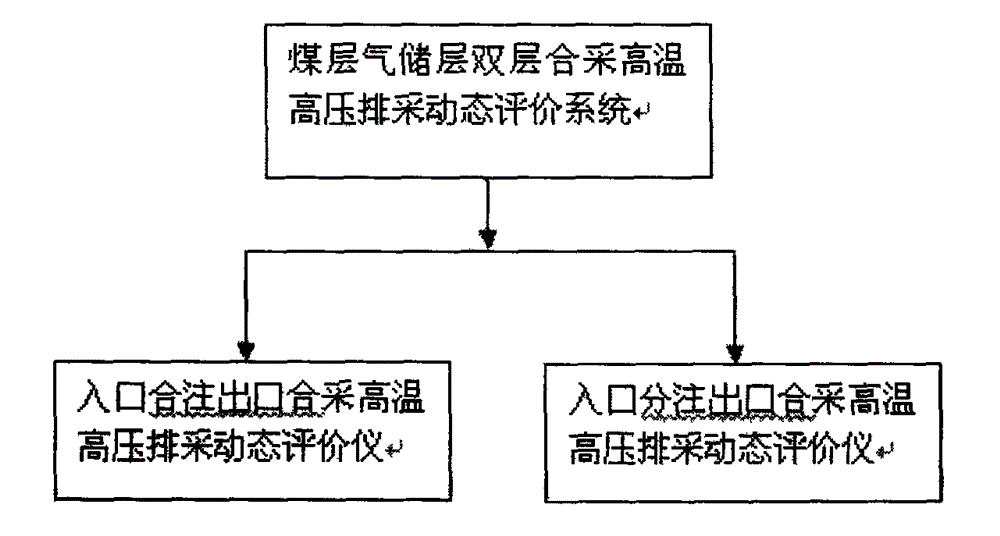

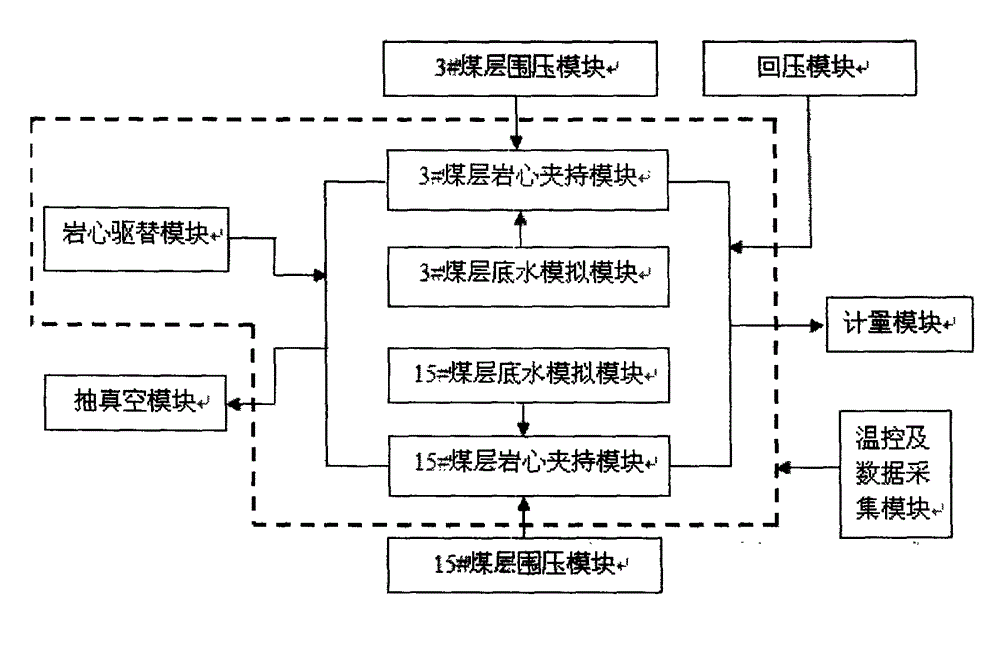

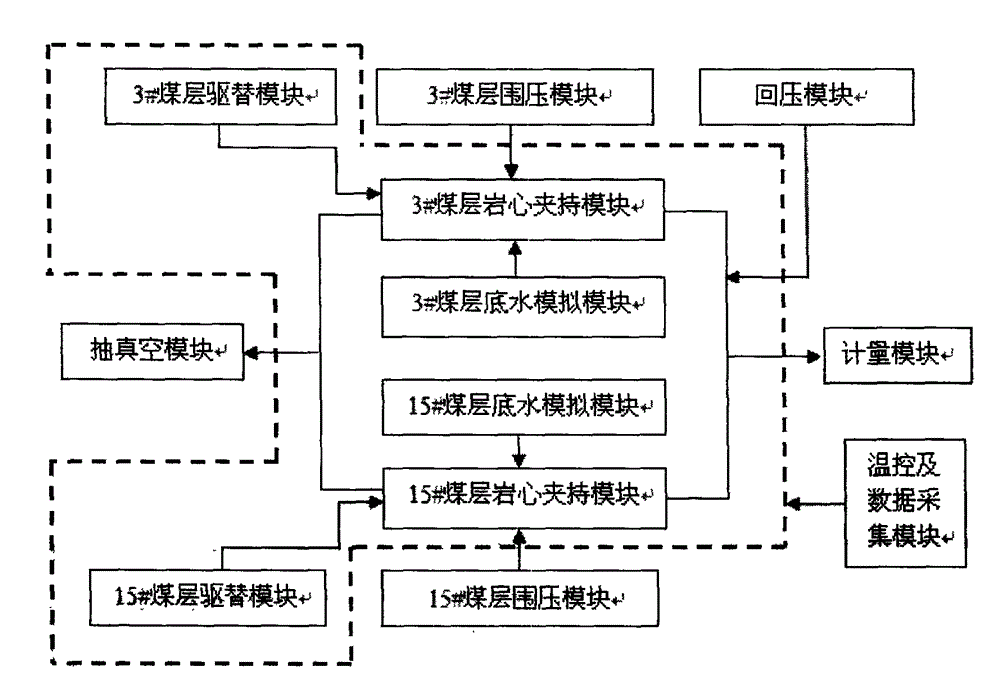

[0039] figure 1 , 2 , 3 show the structure of the dynamic evaluation system for high temperature and high pressure drainage and production of double-layer commingled production of coalbed methane reservoirs provided by the embodiment of the present invention. Only the parts related to the present invention are shown for the convenience of explanation.

[0040] The coalbed methane reservoir double-layer commingled high temperature and high press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com