Unconventional natural gas content automatic measuring apparatus and measuring method thereof

An unconventional natural gas, automatic measurement technology, used in measurement devices, liquid/fluid solid measurement, instruments, etc., can solve the problems of human operation and reading errors, large size of instruments and difficult to carry, affecting the accuracy of measurement, etc. Simple, save the cost of testing human resources, and have the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

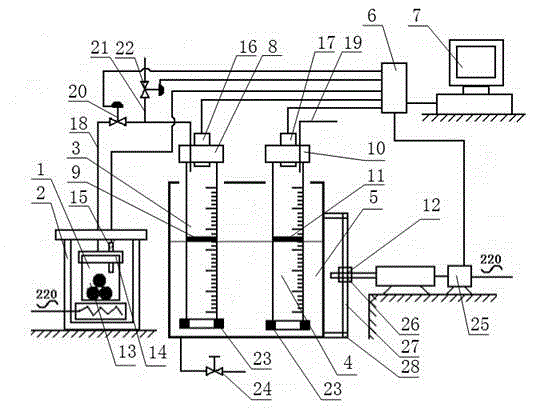

[0027] like figure 1As shown, an automatic measuring instrument for unconventional natural gas content includes an analysis tank 1, a constant temperature water bath box 2, a gas collecting graduated cylinder 3, a balance graduated cylinder 4, a liquid storage tank 5, a data acquisition and control system 6 and an upper computer 7. The lower end of the gas measuring cylinder 3 is open and the upper end is sealed by the sealing cover A8, the gas collecting measuring cylinder 3 is provided with a floating sheet A9, the lower end of the balance measuring cylinder 4 is open and the upper end is sealed by the sealing cover B10, and the gas collecting measuring cylinder 3 is provided with a floating sheet B11. The lower ports of the cylinder 3 and the measuring cylinder 4 are both arranged below the liquid level of the liquid storage tank 5. The liquid storage tank 5 is also connected with a lifting device 12 that drives its up and down movement. The analysis tank 1 is placed in the ...

Embodiment 2

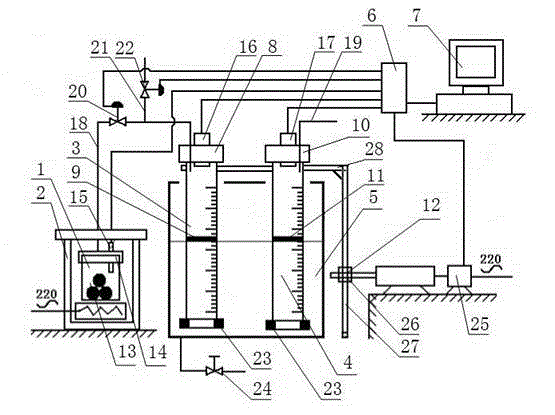

[0040] like figure 2 As shown, an automatic measuring instrument for unconventional natural gas content includes an analysis tank 1, a constant temperature water bath box 2, a gas collecting graduated cylinder 3, a balance graduated cylinder 4, a liquid storage tank 5, a data acquisition and control system 6 and an upper computer 7. The lower end of the gas measuring cylinder 3 is open and the upper end is sealed by the sealing cover A8, the gas collecting measuring cylinder 3 is provided with a floating sheet A9, the lower end of the balance measuring cylinder 4 is open and the upper end is sealed by the sealing cover B10, and the gas collecting measuring cylinder 3 is provided with a floating sheet B11. The lower ports of the cylinder 3 and the measuring cylinder 4 are both arranged below the liquid level of the liquid storage tank 5. The gas collecting measuring cylinder 3 and the measuring cylinder 4 are also connected with a lifting device 12 that drives the gas collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com