Method and device for detecting defects of toughened glass insulator

A technology for tempered glass and defect detection, which is applied in the direction of optical testing for defects/defects, and can solve the problems of inability to perform quality inspection and control of tempered glass insulators, and difficulty in separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

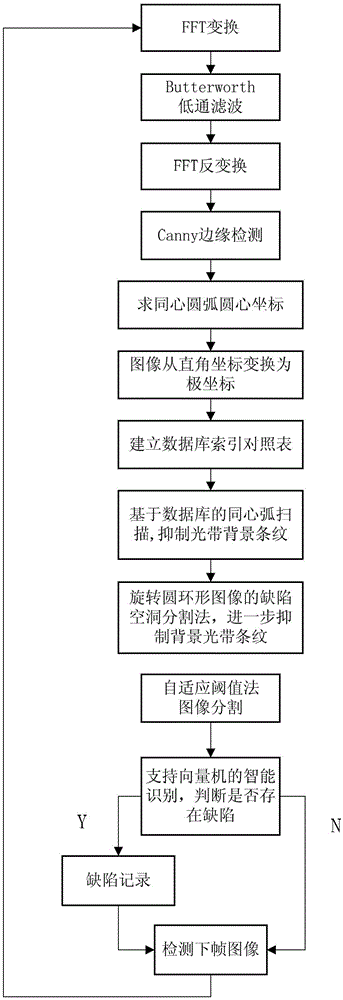

Method used

Image

Examples

Embodiment Construction

[0052] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

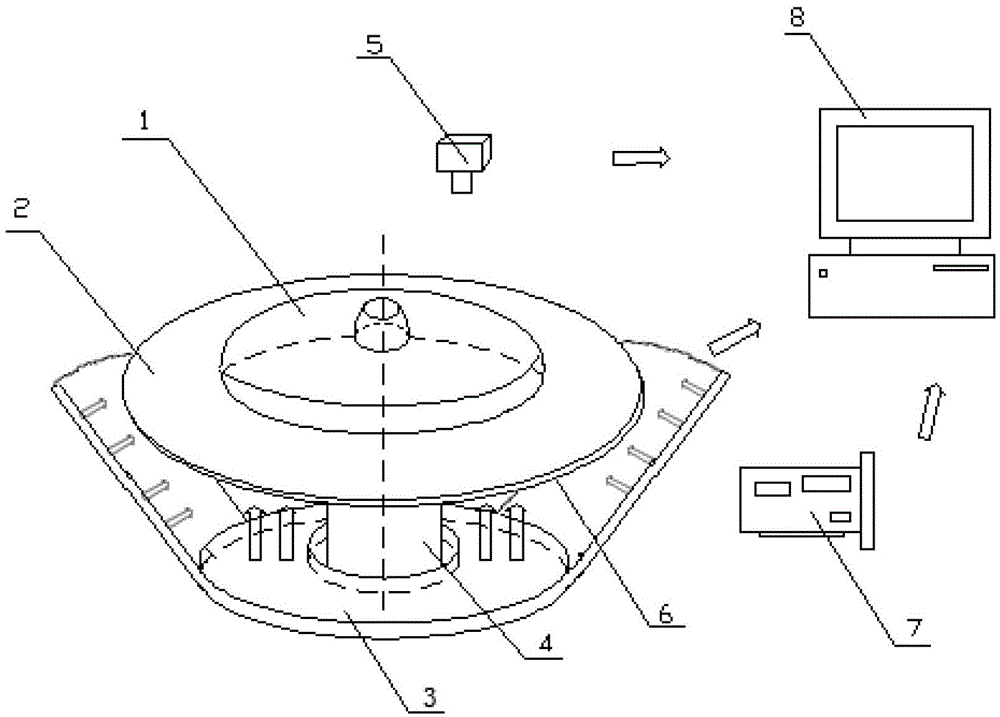

[0053] The concentric arc scanning-based defect detection device for tempered glass insulators involved in this embodiment consists of an optical imaging system, an image acquisition system, and a rotation control system.

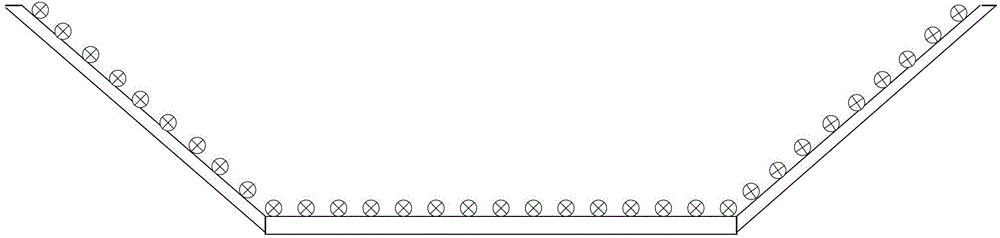

[0054] Such as figure 1 As shown: the above device includes: frosted plexiglass tray 2, LED white light source 3, stepper motor 4, CCD camera 5, rotary console 6, programmable PLC 7, computer 8. Wherein, the frosted plexiglass tray 2 and the stepper motor 4 are connected by a coupling, and the rotation of the stepper motor 4 drives the frosted plexiglass tray 2 to rotate, and the insulator to be detected is placed on the frosted plexiglass tray 2 and rotates together; The light source is placed under the frosted plexiglass tray 2, and can be arranged on the bottom of the insulator with a plane light source. The present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com