Bus connector

A busbar connector and integrated technology, applied in connection, conductive connection, electrical component connection, etc., can solve the problems of quality limited busbar connector quality, increased safety hazards of products, and complicated busbar connection, so as to improve electrical performance and simplify The difficulty of installation and the effect of reducing cost loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing 1 to Fig. 4 the present invention will be further described:

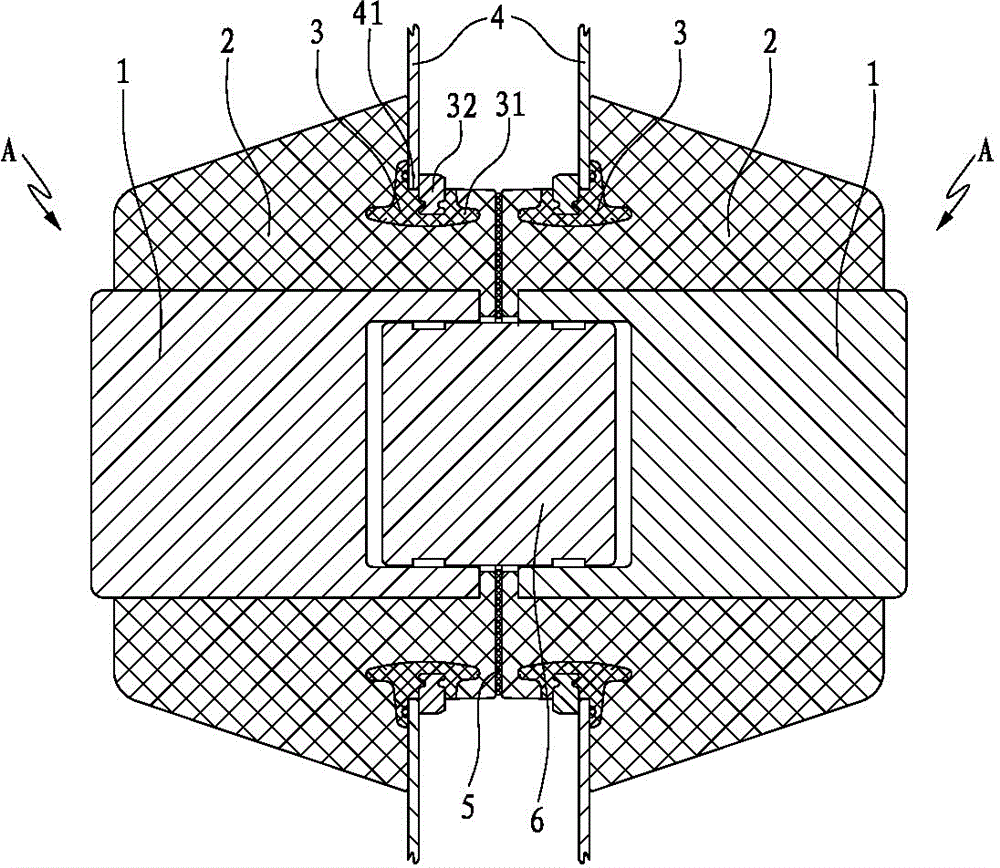

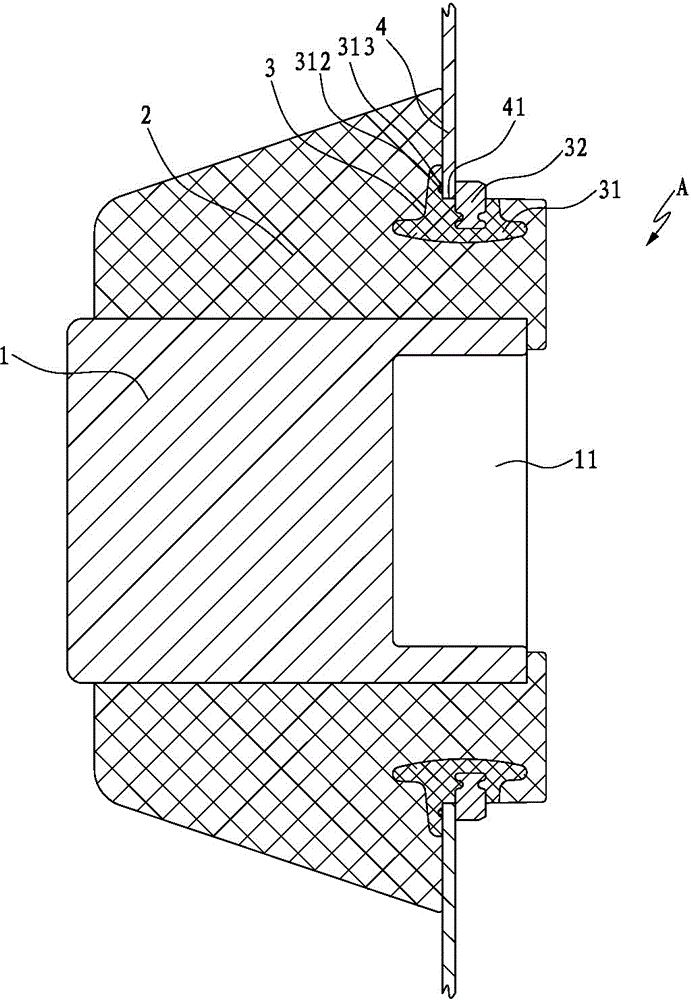

[0022] As shown in Figure 1, the present invention discloses a busbar connector, which includes two symmetrical female connectors A, left and right air box mounting plates 4 connected to the female connectors A, a gasket 5 and a conductive inner core 6; and Each female connector A includes an inner conductive part 1 , an insulating layer 2 and a shielding cover 3 .

[0023] As shown in FIG. 1 , the inside of the inner conductive member 1 is formed with a groove 11 matching the conductive inner core 6; while the outer edge of the inner conductive member 1 is covered with an insulating layer 2, and the inner side of the insulating layer 2 is formed with a constriction 21 to penetrate Through the matching hole 41 of the air box mounting plate 4.

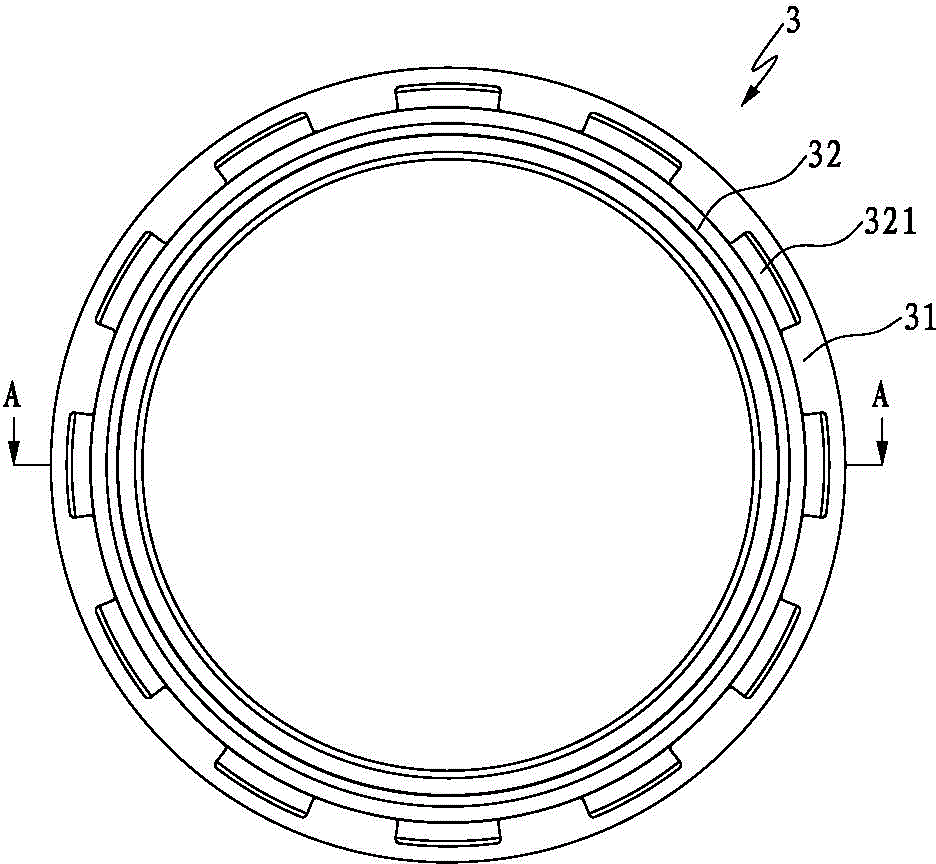

[0024] As shown in Figures 3 and 4, the shielding cover 3 is a ring body fitted to the bottom of the neck 21 of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com