Sealing assembly

A sealing device and sealing element technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of high equipment costs and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

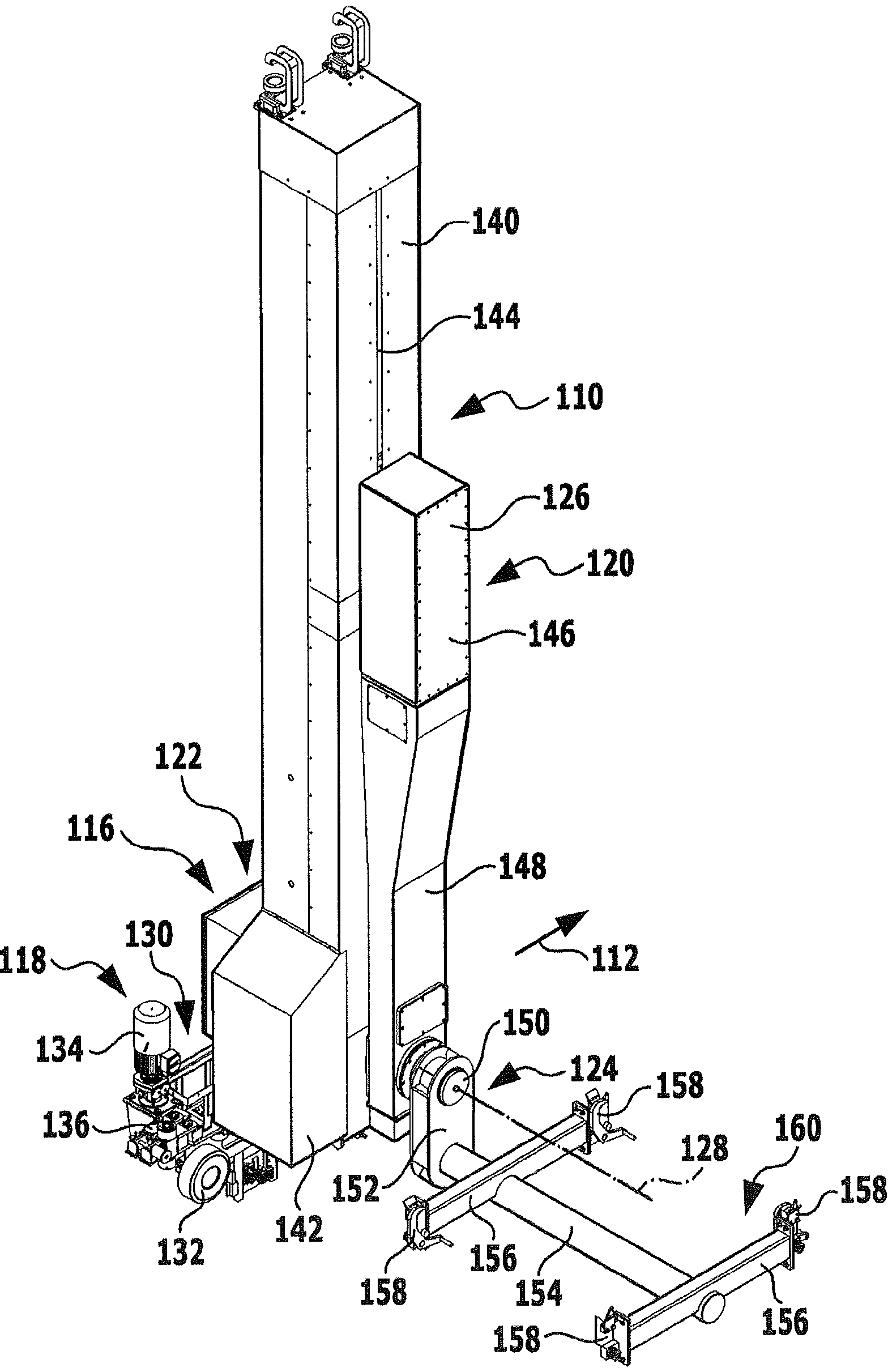

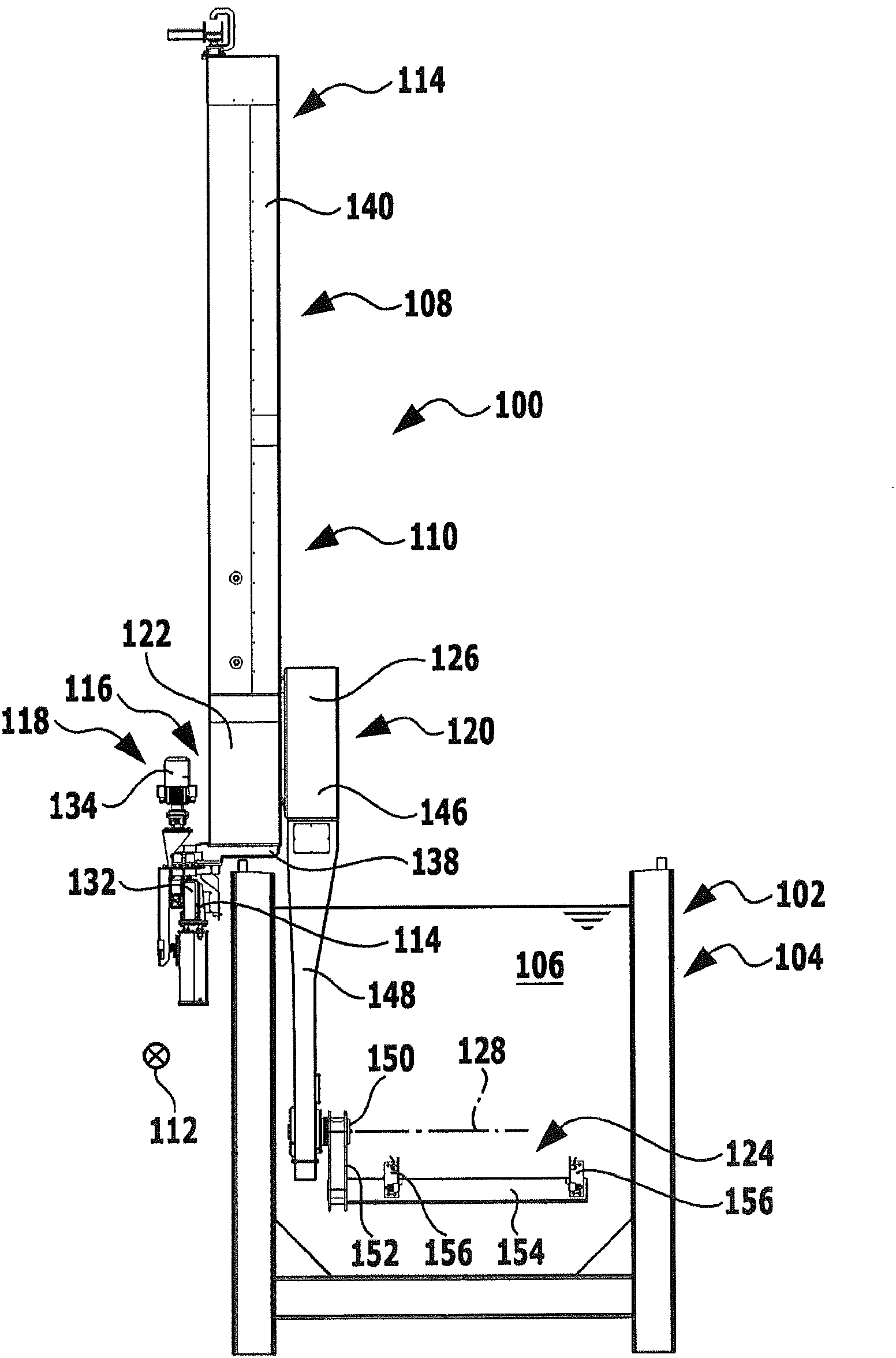

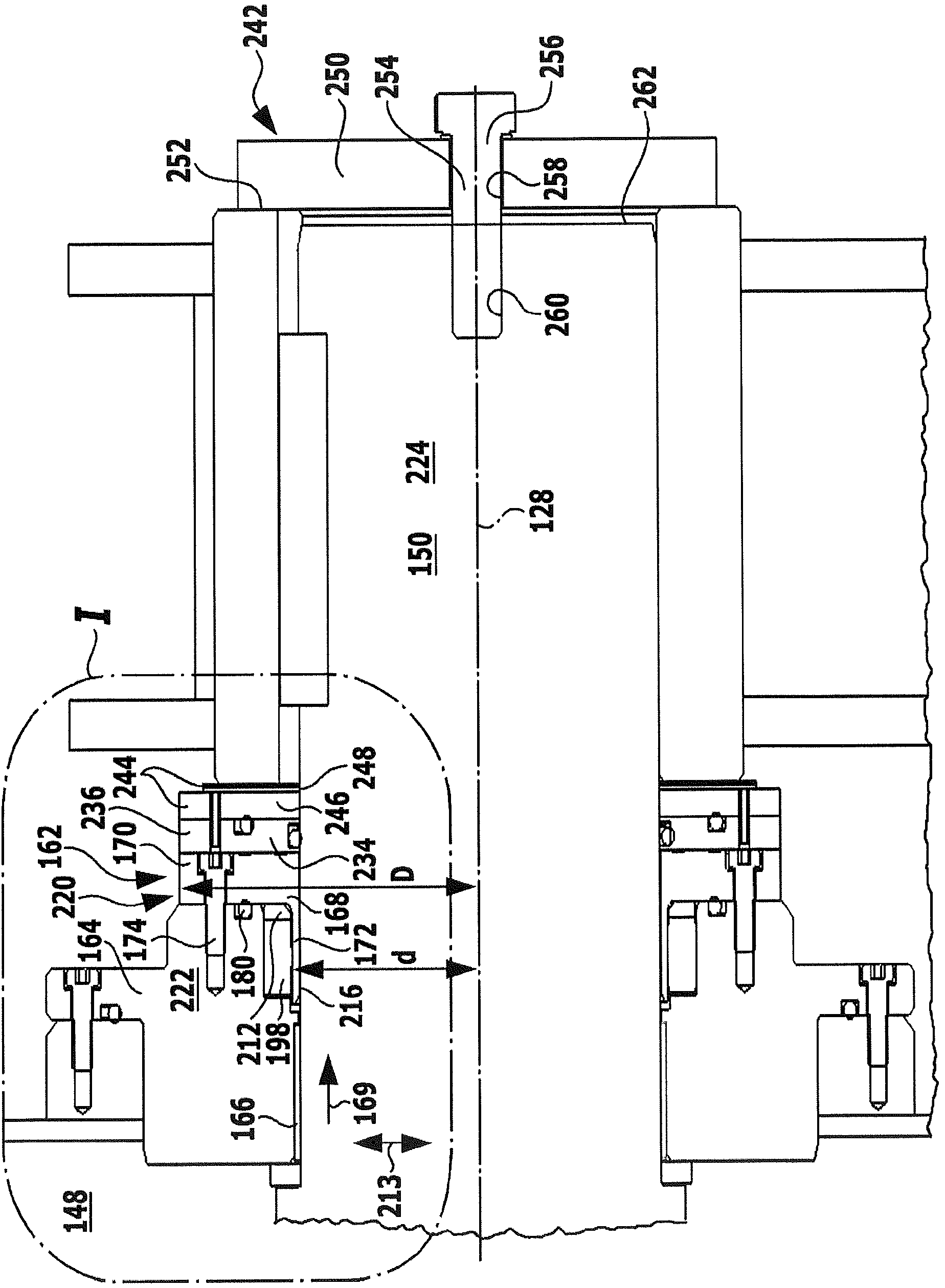

[0080] exist Figures 1 to 4 A device for the surface treatment of workpieces, in particular (not shown) vehicle bodies, is shown in FIG.

[0081] The device 100 comprises at least one treatment area 102, but may also comprise a plurality of successively arranged treatment areas.

[0082] In particular, the treatment region 102 can be designed as a treatment basin 106 for a treatment liquid arranged in a treatment tank 104 .

[0083] If the device 100 is, for example, a device for electrophoretic or self-coating of workpieces, then the treatment area 102 is formed by a bath of electrophoretic or self-coating arranged in a dipping tank.

[0084] However, the device 100 can also be a pretreatment device for pretreatment of workpiece surfaces which are subsequently to be painted or a cleaning device for cleaning workpiece surfaces which are then to be further processed.

[0085] Especially in the case of a cleaning device, the treatment area 102 does not necessarily include a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com