A preparation method of self-cleaning anti-reflection film suitable for heat collecting tube

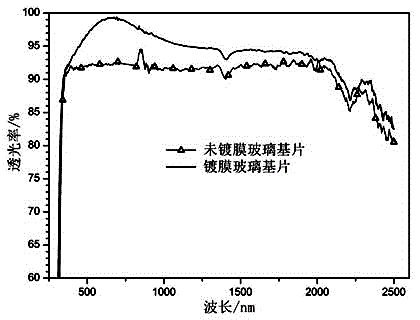

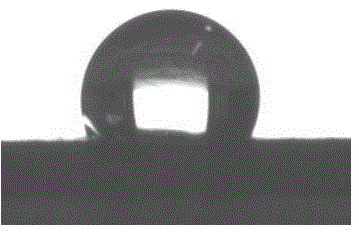

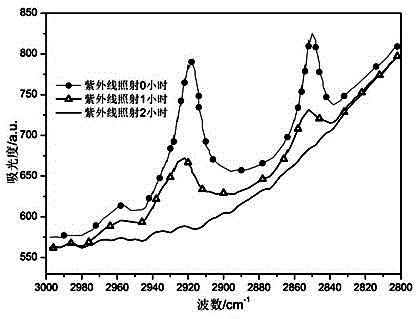

An anti-reflection film and self-cleaning technology, applied in the field of nano-film materials, can solve problems such as the reduction of light transmittance of thin films, and achieve the effects of low cost, high light transmittance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 926ml of isopropanol and add it to a 2000ml three-necked flask, then turn on the stirrer, continue to add 46ml of tetraethyl orthosilicate and 28ml of deionized water to the flask while stirring, continue to stir, and add 3mol / 1 L of hydrochloric acid, adjust the pH value to 4 and keep it constant. After the hydrochloric acid has been added dropwise, continue to stir at room temperature for 1 hour, then leave it to age for 6 hours, and then add 18.5 g of molecular weight 1000 in the aged solution. Polyethylene glycol was stirred continuously for 1 hour to prepare Sol A for use.

[0024] Take 524ml of isopropanol and add it to a 2000ml three-neck flask, then turn on the stirrer, and continue to add 209ml of tetrabutyl titanate, 209ml of tetrabutyl titanate, 31ml of ethyl acetoacetate, and 209ml of deionized water into the flask while stirring. Then, 3 mol / L hydrochloric acid was added dropwise while stirring continuously to adjust the pH value to 4, stirring was co...

Embodiment 2

[0030] Take 806ml of isopropanol and add it to a 2000ml three-necked flask, then turn on the stirrer, continue to add 121ml of tetraethyl orthosilicate and 73ml of deionized water to the flask while stirring, continue to stir, and drop 3mol / 1 L of hydrochloric acid, adjust the pH value to 5 and keep it constant. After the hydrochloric acid has been added dropwise, continue to stir for 2 hours at room temperature, then leave it to age for 8 hours, then add 24g of polymer with a molecular weight of 1000 in the aged solution. Ethylene glycol was stirred continuously for 2 hours to obtain Sol A for use.

[0031] Take 452ml of isopropanol and add it to a 2000ml three-necked flask, then turn on the stirrer, and continue to add 226ml of tetrabutyl orthosilicate, 68ml of tetrabutyl titanate, 27ml of ethyl acetoacetate, and 226ml of deionized water into the flask while stirring. Then, 3 mol / L hydrochloric acid was added dropwise while stirring continuously, the pH value was adjusted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com