Tobacco processing method of extracting flavor components in tobacco using fog media

A processing method and a technology of flavoring substances, which are applied in the field of tobacco, can solve problems such as harm to the body, and achieve the effect of mellow and delicate entrance, improved safety in use, and rich layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

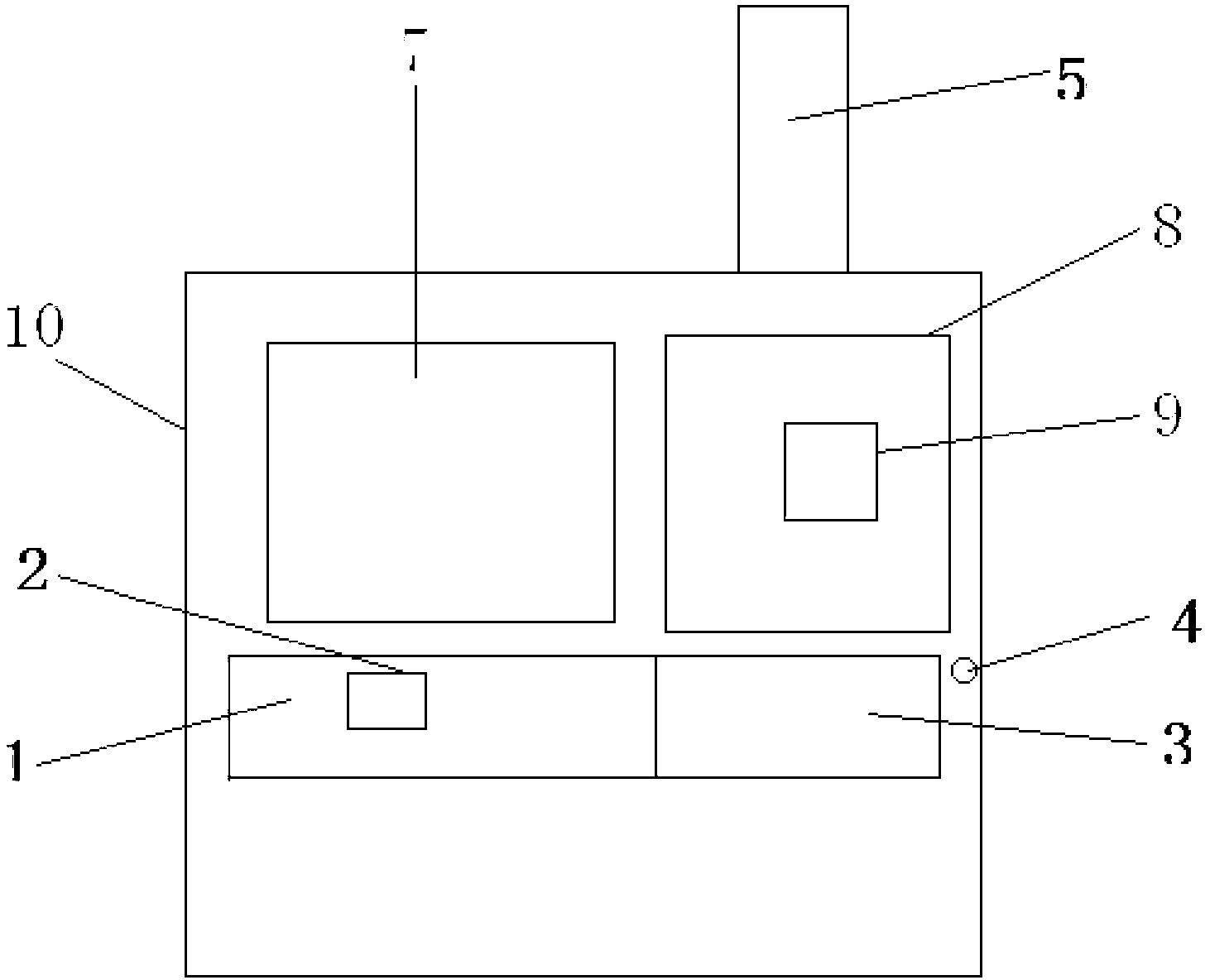

[0040] like figure 1 As shown, the present invention provides a tobacco leaf suction device in a cigarette box, the tobacco leaf suction device is box-shaped, and also includes a hollow cigarette box-shaped casing 10, the control element 7, the airflow sensor 3, the atomization device 1 and the heating device 8 are located in the cigarette case-shaped casing 10, one end of the smoking port 5 communicates with the heating device 8 in the cigarette-case-shaped casing 10, and the other end extends out of the casing of the cigarette-case-shaped casing 10. The air inlet 4 protrudes from the cigarette box-shaped housing 10 housing.

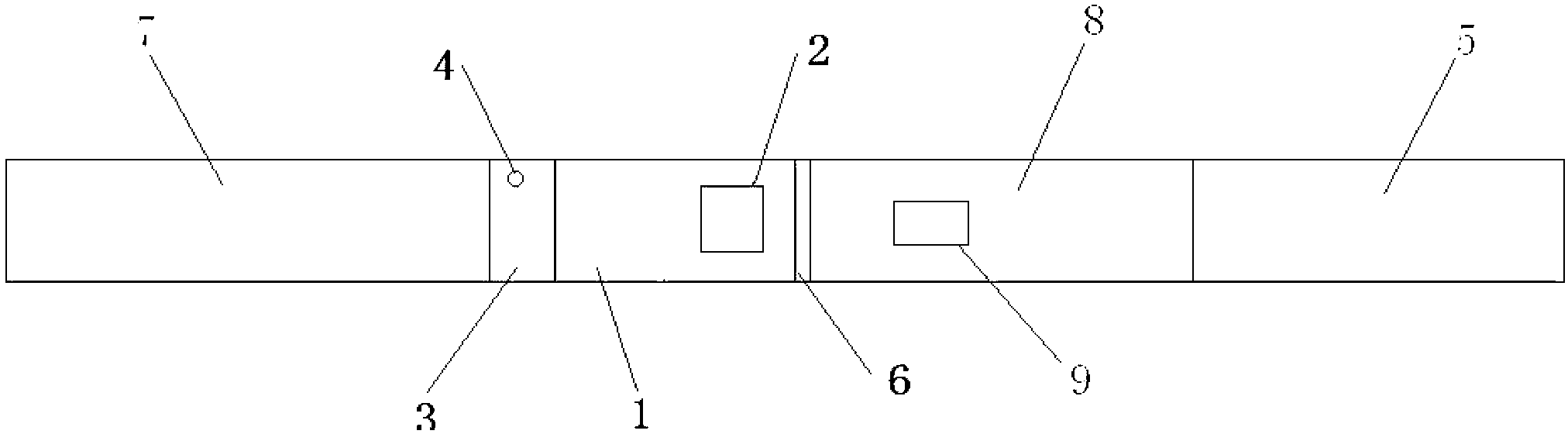

[0041] like figure 2 As shown, the present invention provides a cigarette-shaped tobacco leaf suction device, which is provided with a control element 7, an airflow sensor 3, an atomizing device 1, a heating device 8 and a smoking port 5 arranged in sequence from the head to the tail of the cigarette, The control element 7 is connected to the airflow...

Embodiment 2

[0045] Table 1

[0046]

[0047] The flue-cured tobacco used in the embodiment is that the place of production is Guizhou, and the grade is the flue-cured tobacco of C2F;

[0048] The burley tobacco used in the embodiment is that the place of production is Hubei, and the grade is the burley tobacco of middle one;

[0049] The sun-cured tobacco used in the embodiment is the sun-cured tobacco whose place of production is Guangxi and whose grade is the first grade;

[0050] The oriental tobacco used in the examples is the oriental tobacco produced in Xinjiang and graded as AP.

[0051] Using the example as figure 1 The shown device evaluates the taste effect of the tobacco leaf processing method of the present invention on different tobacco leaf products. The tobacco leaf products of 4 formulas are sucked using the corresponding mist medium, and the sensory evaluation is carried out. The evaluation results are shown in Table 2 (refer to the national standard GB 5606.4-2005 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com