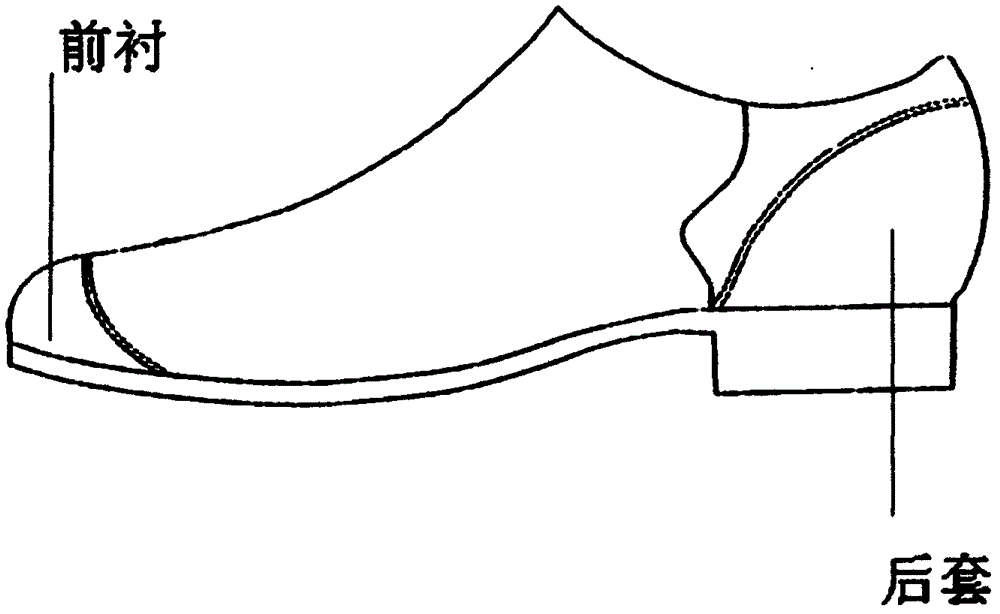

Production machine of front linings and heel caps of shoes

A technology for producing machines and front linings, applied in the direction of shoemaking machinery, shoe uppers, footwear, etc., can solve the problems of increasing human resources input, increasing labor costs, increasing production costs, etc., to save labor costs, high production efficiency, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] There are many ways to realize the present invention, and the following preferred examples are for the public to better understand the technical content described in the present invention, rather than limiting the technical content. In fact, any additions, subtractions, replacements and improvements to any element that do not violate the spirit of the invention described in the present invention are within the technical solutions claimed by the present invention.

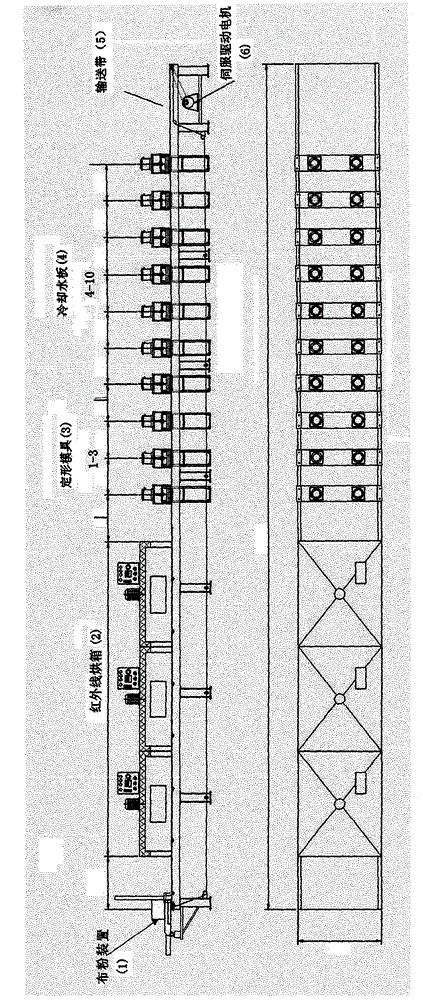

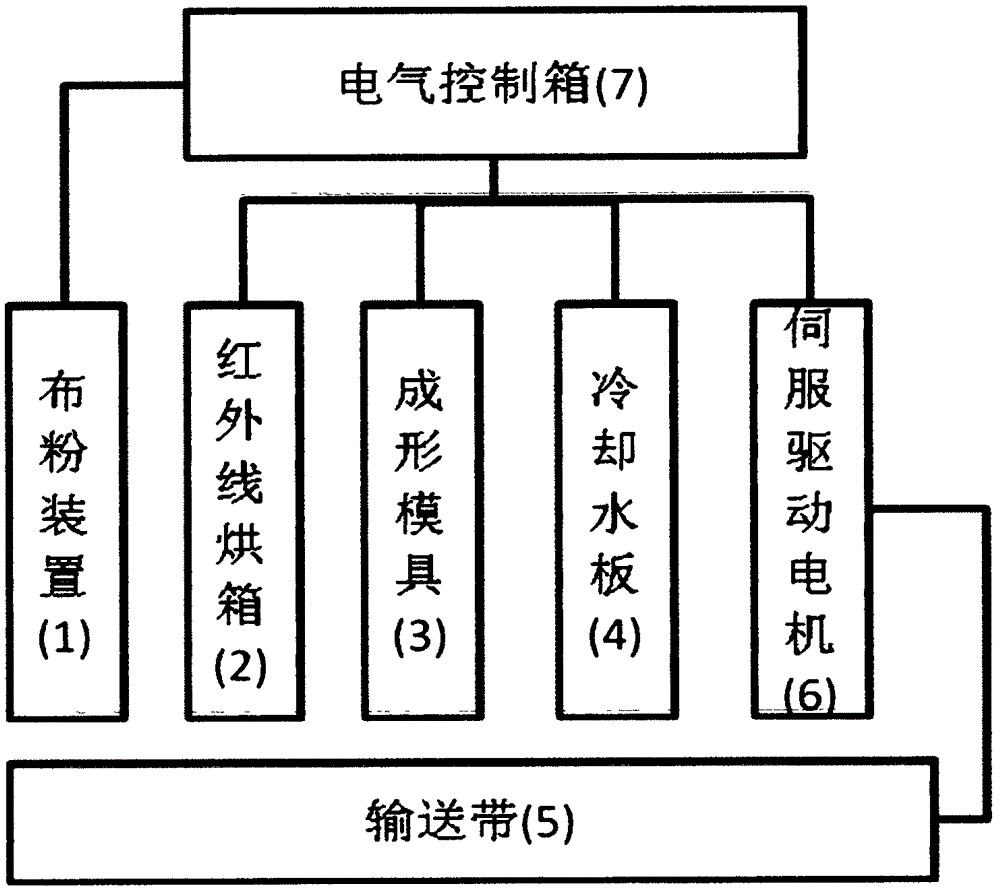

[0033] See attached image 3 , a production machine for the front lining and back cover of shoes, which consists of a powder distributing device (1), an oven (2), a forming mold (3), a cooling water plate (4), a conveyor belt (5), and a servo drive motor (6) Composed of an electrical control box (7). Among them, in order to improve production efficiency, there are 3 sets of ovens, 3 sets of forming molds, and 7 sets of cooling water plates, which are controlled by the electric control box and work in a coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com