Tracing type bio-based scale inhibitor as well as preparation method and application thereof

A bio-based, antiscalant technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problems of cumbersome preparation process and difficult large-scale production, and achieve the goal of preparation process Simple, excellent calcium sulfate inhibition performance, high scale inhibition efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

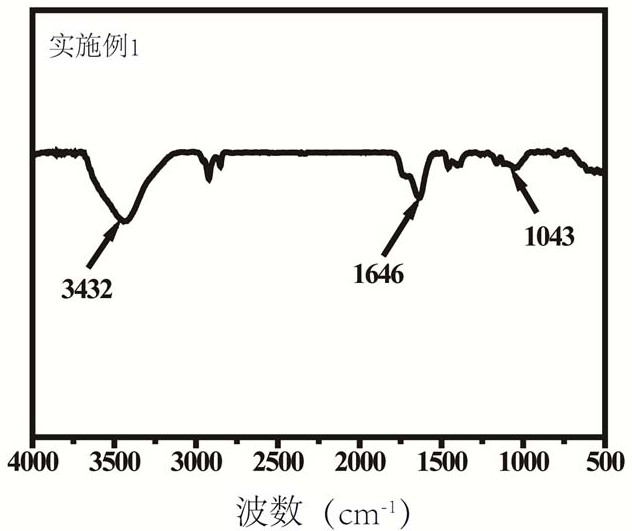

Embodiment 1

[0033] Under the condition of mechanical stirring (the mechanical stirring speed is 300r / min), dissolve trisodium 8-hydroxy-1,3,6-pyrene trisulfonate in methanol solution and pour it into a four-neck flask, then add triethylamine solution. Finally, under the condition of water bath heating (heating temperature is 40 o C) Slowly add glycidyl methacrylate (8-hydroxy-1,3,6-trisodium pyrenetrisulfonate, triethylamine, glycidyl methacrylate , The mass ratio of methanol is 1:1:2:3000), after the dropwise addition, continue to heat the reaction (reaction time is 8h). After the reaction, pour the solution into a flask, and use a rotary evaporator to extract the solvent methanol to obtain the final product monomer with a fluorescent group;

[0034] Weigh a certain amount of chitosan, add it to the hydrochloric acid solution (the mass ratio of chitosan, hydrochloric acid, and water is 1:4:100), under the condition of magnetic stirring (magnetic stirring speed is 120r / min), wait until ...

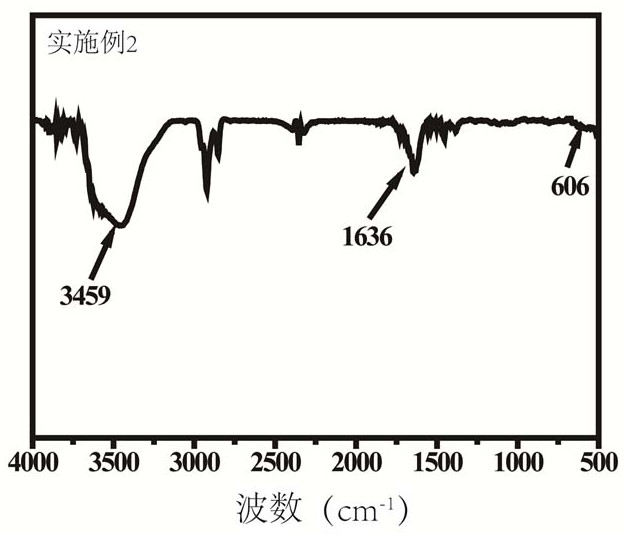

Embodiment 2

[0038] Under the condition of mechanical stirring (the mechanical stirring speed is 300r / min), dissolve trisodium 8-hydroxy-1,3,6-pyrene trisulfonate in methanol solution and pour it into a four-neck flask, then add triethylamine solution. Finally, under the condition of water bath heating (heating temperature is 50 o C) Slowly add glycidyl methacrylate (8-hydroxy-1,3,6-trisodium pyrenetrisulfonate, triethylamine, glycidyl methacrylate , The mass ratio of methanol is 1:0.1:0.5:2000), after the dropwise addition, continue to heat the reaction (reaction time is 6h). After the reaction, pour the solution into a flask, and use a rotary evaporator to extract the solvent methanol to obtain the final product monomer with a fluorescent group;

[0039] Weigh a certain amount of chitosan, add it to the hydrochloric acid solution (the mass ratio of chitosan, hydrochloric acid, and water is 1:2:80), under the condition of magnetic stirring (magnetic stirring speed is 120r / min), wait unt...

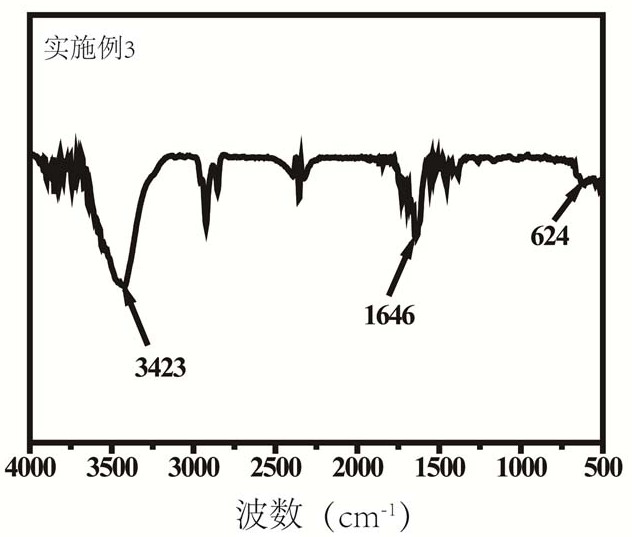

Embodiment 3

[0043] Under the condition of mechanical stirring (the mechanical stirring speed is 300r / min), dissolve trisodium 8-hydroxy-1,3,6-pyrene trisulfonate in methanol solution and pour it into a four-neck flask, then add triethylamine solution. Finally, under the condition of water bath heating (heating temperature is 70 o C) Slowly add glycidyl methacrylate (8-hydroxy-1,3,6-trisodium pyrenetrisulfonate, triethylamine, glycidyl methacrylate , The mass ratio of methanol is 1:2:0.1:2000), after the dropwise addition, continue to heat the reaction (reaction time is 10h). After the reaction, pour the solution into a flask, and use a rotary evaporator to extract the solvent methanol to obtain the final product monomer with a fluorescent group;

[0044] Weigh a certain amount of chitosan, add it to hydrochloric acid solution (mass ratio of chitosan, hydrochloric acid, water is 1:3:150), under the condition of magnetic stirring (magnetic stirring speed is 120r / min), wait for Chitosan w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com