Method for preparing biodiesel without by-product of glycerin by utilization of high acid value waste oil

A technology of biodiesel and high acid value, which is applied in the fields of biofuel, fat production, fat oil/fat refining, etc. It can solve the problems of limited water absorption capacity of water-absorbing agents, decreased catalytic activity, and difficult separation of immobilized enzymes and molecular sieves. The effect of high preprocessing cost and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

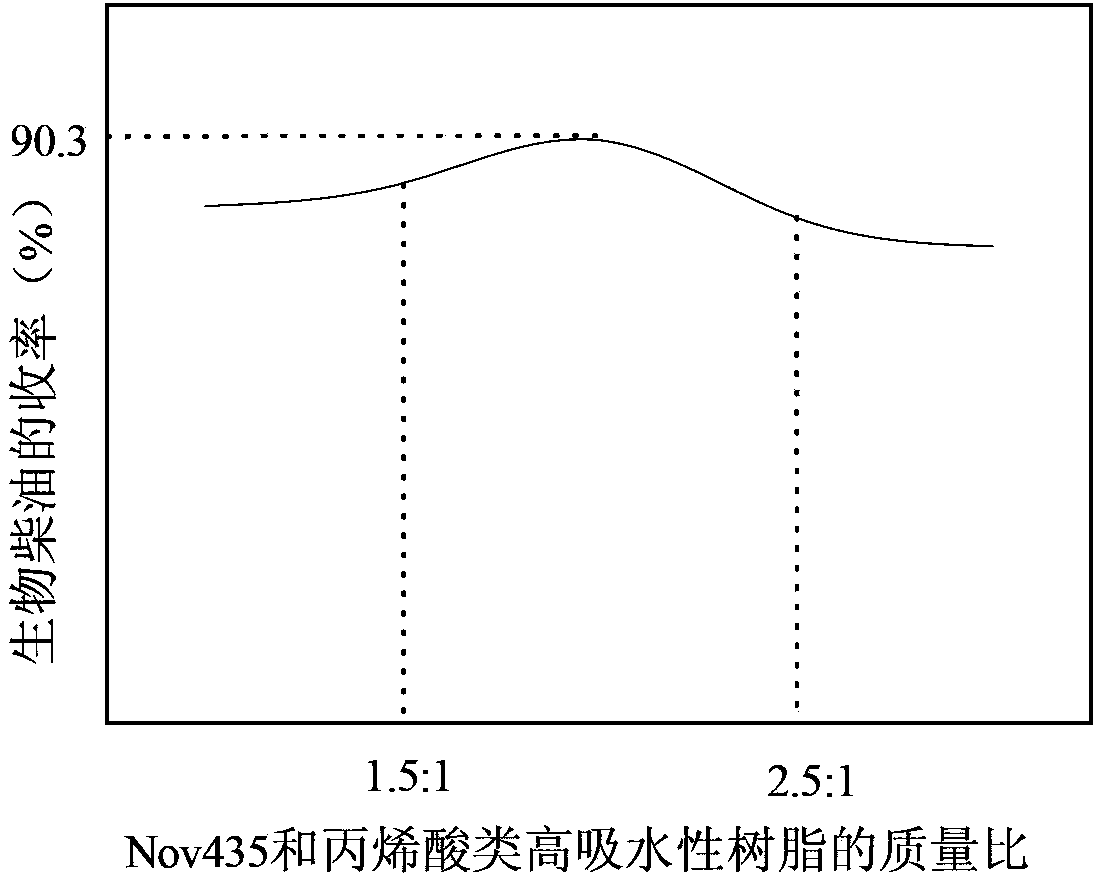

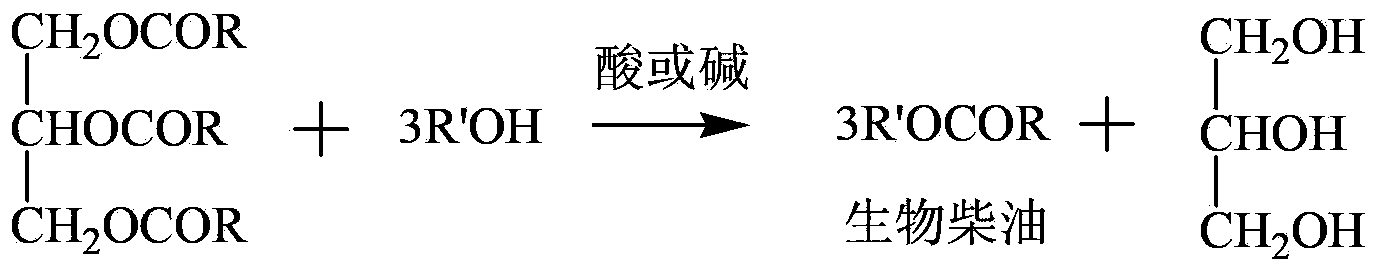

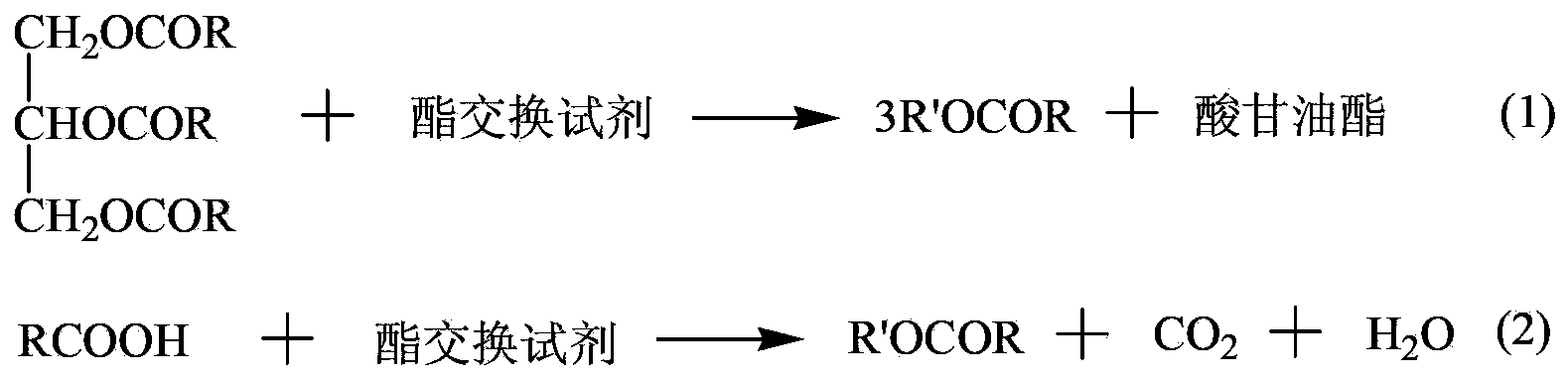

[0034] Add 5g corn waste oil with high acid value (acid value 67mgKOH / g), 8.2g dimethyl carbonate, 1.5g Novozym435 / acrylic superabsorbent resin composite catalyst (mass ratio 2:1) into a stoppered Erlenmeyer flask, After reacting in a constant temperature water-bath shaker at 60°C for 24 hours, the catalyst was separated and recovered by filtration, and the excess dimethyl carbonate was removed by rotary evaporation of the filtrate, and there was no separation of glycerin after standing, and no free glycerin was detected by gas chromatography analysis. Biological The yield of diesel oil reaches 90.1%.

Embodiment 2

[0036]Add 5g of corn waste oil with high acid value (acid value: 67mgKOH / g), 8.2g of dimethyl carbonate, and the composite catalyst recovered in Example 1 into a stoppered Erlenmeyer flask, and react in a constant temperature water bath shaker at 60°C for 24h Finally, the catalyst was separated and recovered by filtration, the excess dimethyl carbonate was removed by rotary evaporation in the filtrate, and no glycerol stratification occurred after standing. No free glycerin was detected by gas chromatography analysis, and the yield of biodiesel reached 90.3%.

[0037] According to the method of examples 1 and 2, the composite catalyst is used more than 20 times, and the yield of biodiesel is maintained at about 90%, which has good stability and reusability.

Embodiment 3

[0044] Add 5g of corn high acid value leached crude oil (acid value 160mgKOH / g), 8.2g of dimethyl carbonate, 1.5g of Novozym435 / acrylic superabsorbent resin composite catalyst (mass ratio 2:1) into the plugged triangle In the flask, after reacting in a constant temperature water bath shaker at 60°C for 12 hours, the catalyst was separated and recovered by filtration, and the excess dimethyl carbonate was removed by rotary evaporation in the filtrate, and there was no separation of glycerin after standing, and no free dimethyl carbonate was detected by gas chromatography analysis. The yield of glycerol and biodiesel reached 86.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com