Inner extrusion coating device and extrusion coating method

A technology of internal extrusion coating and flange, which is applied to the surface coating liquid device, coating, heating inorganic powder coating, etc., can solve the problem of not having a good coating device for the inner wall of cylinder parts, and achieve thickness Easy-to-control, evenly applied results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

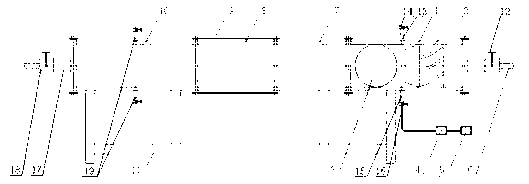

[0019] Such as figure 1 As shown in the schematic diagram of the structure of the extrusion coating device, it at least includes the extrusion coating device body part fixed on the frame 11. The extrusion coating device body is composed of the launch section 1, the stabilizing section 7, the same inner diameter of the cylinder to be repaired. The receiving section 10 is composed of the transmitting section 1 and the stabilizing section 7 are fixedly connected by a flange, and the flange connection is sealed by an annular rubber ring or a rubber pad, and the two ends of the cylinder 8 to be repaired are connected to the stabilizing section 7 and the receiving section respectively. The segments 10 are detachably connected by screw rods.

[0020] One end of the launch section 1 is fixedly connected to the stable section 7 through a flange, and the other end is fixed with a plug through the flange. The middle part of the plug is a compressed air inlet 6, and the launch section 1 i...

Embodiment 2

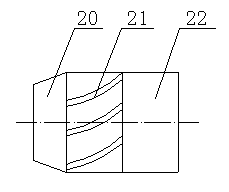

[0028] Such as figure 2 As shown in the structural schematic diagram of the rotary extrusion coating device, the rotary extrusion coating device 2 in the above embodiment is an integrated structure formed by sequentially connecting and fixing the tapered section 20, the helical section 21 and the extrusion coating section 22. The purpose of the tapered section is to save After the alloy powder enters the helical section, the helical thrust makes the rotary extruder rotate, so that the alloy powder enters the cylinder 8 through the extrusion section, and then the alloy powder is more evenly extruded onto the inner wall of the cylinder 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com