Equipment capable of automatically installing screws

An automatic installation and screw technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of difficulty in ensuring accuracy, low degree of automation, and low efficiency, and achieve convenient inspection, simple operation, and increased operability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

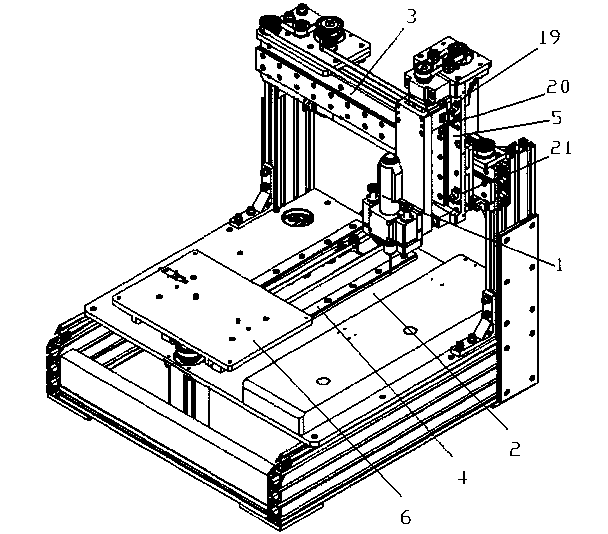

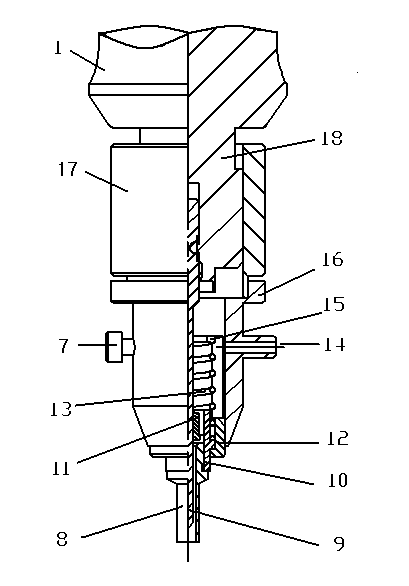

[0018] The following is attached Figure 1-2 Embodiments of the present invention are described in further detail:

[0019] 1 is the electric screwdriver feeding device, 2 is the three-axis platform, 3 is the horizontal running guide rail, 4 is the longitudinal running guide rail, 5 is the height running guide rail, 6 is the tool, 7 is the locking fixing screw, 8 is the vacuum nozzle, 9 is the screwdriver bit, 10 is the suction nozzle fixing sleeve, 11 is the knife head centering sleeve, 12 is the suction nozzle floating wrap sleeve, 13 is the compression spring, 14 is the air channel, 15 is the inner diameter spring, 16 is the air passage introduction sleeve , 17 is a screwdriver torque adjustment ring, 18 is an electric screwdriver handle, 19 is a limit sensor 1, 20 is an origin sensor, and 21 is a limit sensor 2.

[0020] The present invention mainly includes screw feeder, vacuum generator, PLC, touch screen, alarm device, three-axis platform 2, electric screwdriver feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com