Two methods of achieving single-side polishing on double-side polishing machine

A single-side polishing and polishing machine technology, which is applied in the field of polishing, can solve the problems of increasing maintenance costs, use costs, and high equipment investment, and achieve the effect of increasing the number of polishing and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

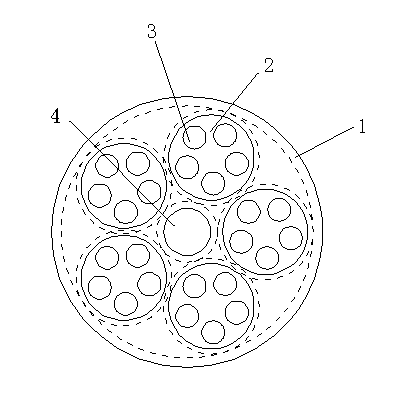

[0032] 1) On the lower grinding disc 5 of the double-sided polishing machine, install the intermeshing inner ring gear 1, the external tooth sun gear 4 and five planetary discs 2 with external teeth. Each planetary disc 2 has five channels. Hole 3.

[0033] 3) Put 25 pieces of crystal material 7 in the through hole 3, the crystal material 7 is suitable for the size of the through hole.

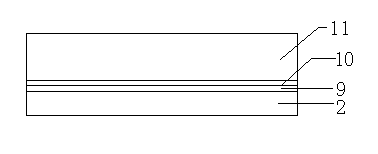

[0034] 3) Put a buffer pad 9, a fixed layer 10, and a briquetting block 11 on each planetary disc 5 in sequence, and the pressure of the briquetting block is 300g / cm 2 .

[0035] 4) Keep the upper grinding disc out of contact with the lower grinding disc for polishing.

[0036] 5) Polishing conditions: the rotational speed of the lower grinding disc: 16~60rpm, the rotational speed ratio of the external gear sun gear and the lower grinding disc is 1:3~1:10.

[0037] In this embodiment, only the lower grinding disc is used to polish the crystal material, realizing single-sided polishing on a ...

no. 2 example

[0040] 1) On the lower grinding disc 5 of the double-sided polishing machine, install the intermeshing inner ring gear 1, the external tooth sun gear 4 and five planetary discs 2 with external teeth. Each planetary disc 2 has five channels. Hole 3.

[0041] 2) The surfaces of 50 crystal materials 7 that do not need to be polished are bonded in pairs with high-temperature wax, and the size of the crystal materials 7 is adapted to the size of the through hole 3 .

[0042] 3) Put the above-mentioned 25 pairs of crystal materials 7 bonded in pairs into the through holes 3 of the planetary disk 2 .

[0043] 4) Cover the upper grinding disc, and polish the upper and lower grinding discs at the same time;

[0044] 5) Polishing process conditions: lower grinding disc speed: 16~60rpm, upper grinding disc speed: 16~60rpm, external gear sun gear and lower grinding disc speed ratio: 1:3~1:10.

[0045] In this embodiment, the upper and lower grinding discs are polished simultaneously, an...

no. 3 example

[0048] 1) On the lower grinding disc 5 of the double-sided polishing machine, install the intermeshing inner ring gear 1, the external tooth sun gear 4 and five planetary discs 2 with external teeth. Each planetary disc 2 has five channels. Hole 3.

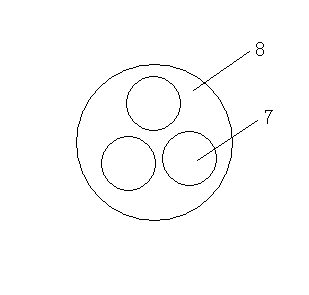

[0049] 2) if image 3 As shown, the surfaces of three smaller crystalline materials 7 that do not need to be polished are stuck on the upper surface of the stainless steel sheet 8 with wax, and the surfaces that do not need to be polished of the other three crystal materials are bonded to the surface of the stainless steel sheet 8 with high-temperature wax. On the lower surface, the size of the stainless steel sheet 8 is compatible with the size of the through hole 3 on the planetary disc 2; repeat the aforementioned operations to obtain 25 pieces of stainless steel sheet 8, each of which is pasted with 6 pieces of crystal material 7.

[0050] 3) Put the above-mentioned 25 pieces of stainless steel sheets 8 in the through holes 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com