Processing device for air bag polishing tool surface polishing pad

A technology of surface polishing and airbag polishing, which is applied in the direction of grinding devices, manufacturing tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

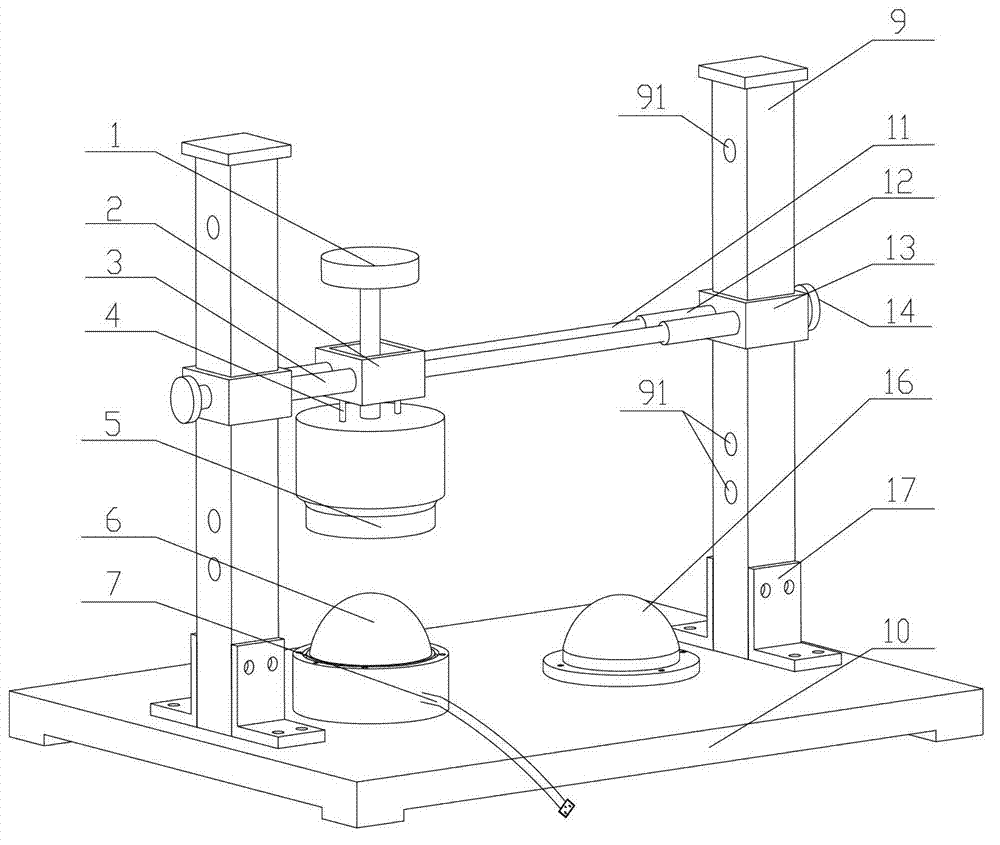

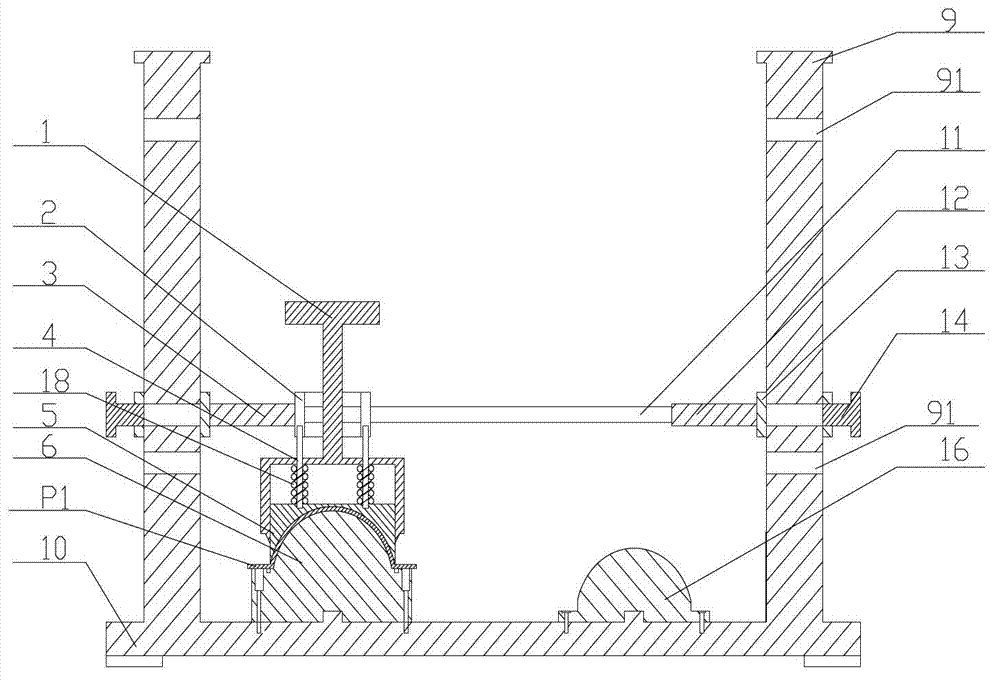

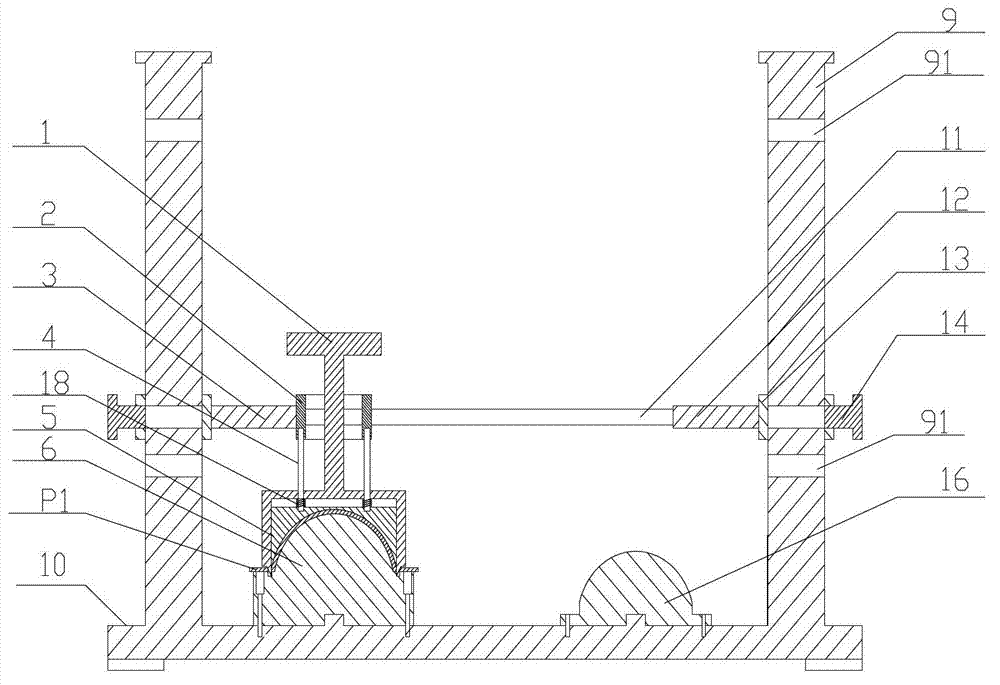

[0021] see figure 1 and 2 , the present invention includes base 10, column 9 (2), guide rail 11 (2), slider 2, left limit block 3, right limit block 12, cup cutter 1, die 5, cutter back Position spring 18, polishing pad molding base mold 6, heating wire 7 and polishing pad glue coating base mold 16; height adjustment block 13 and height fixing pin 14.

[0022] The two uprights 9 are fixed on the base 10 through the upright fixing block 17, and the two uprights 9 are symmetrically provided with bolt holes 91 of different heights. Both ends of the guide rail 11 are respectively connected to a column 9 through a height adjustment block 13 and a height fixing pin 14, the height adjustment block 13 is fixedly connected to the end of the guide rail 11, the height adjustment block 13 is slidably matched with the column 9, and the height fixing pin 14 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com