Car lamp steering system driving device

A technology of steering system and driving device, which is applied in signal devices, vehicle parts, transportation and packaging, etc., and can solve problems such as poor stability of movement displacement and large degree of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

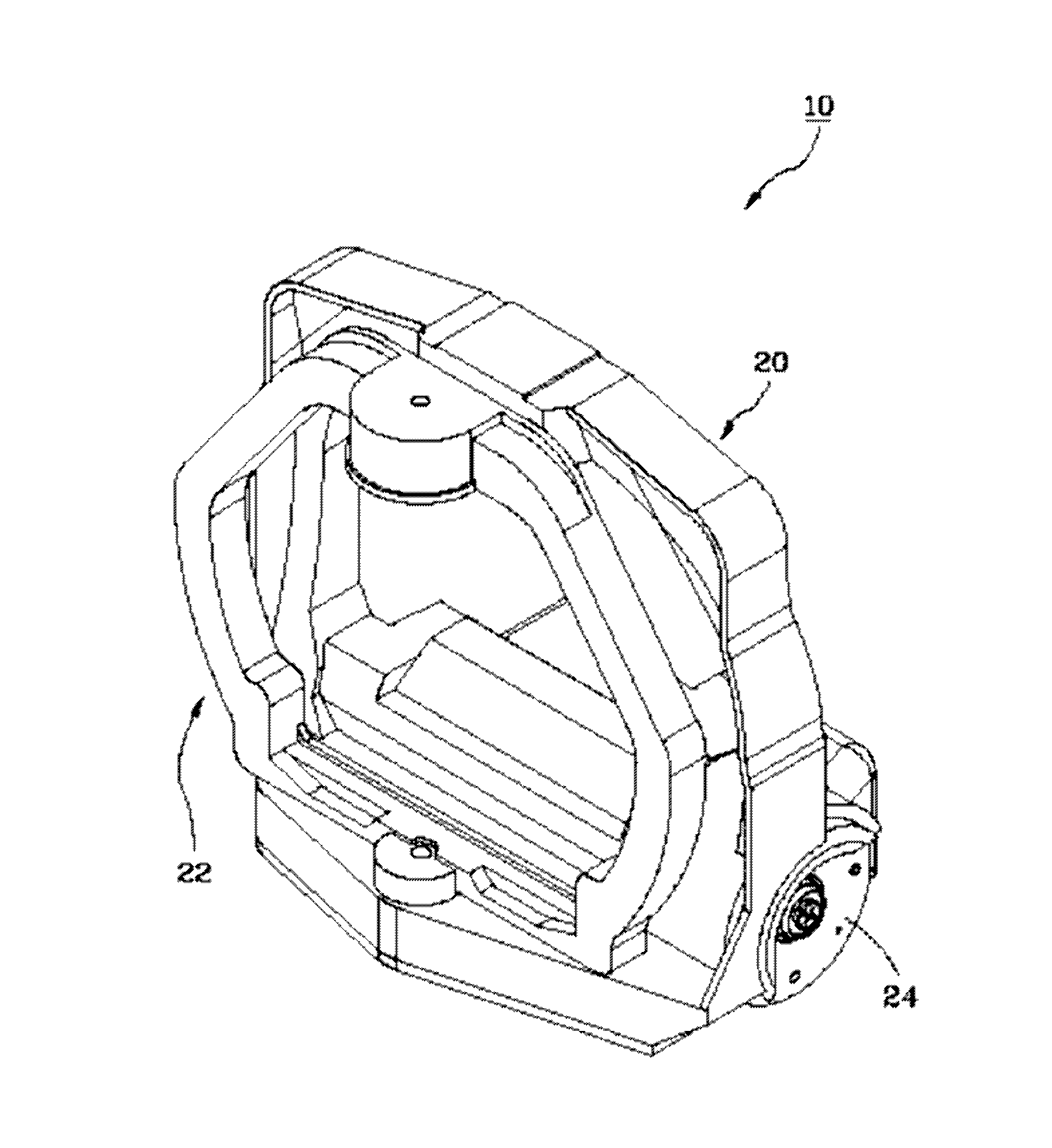

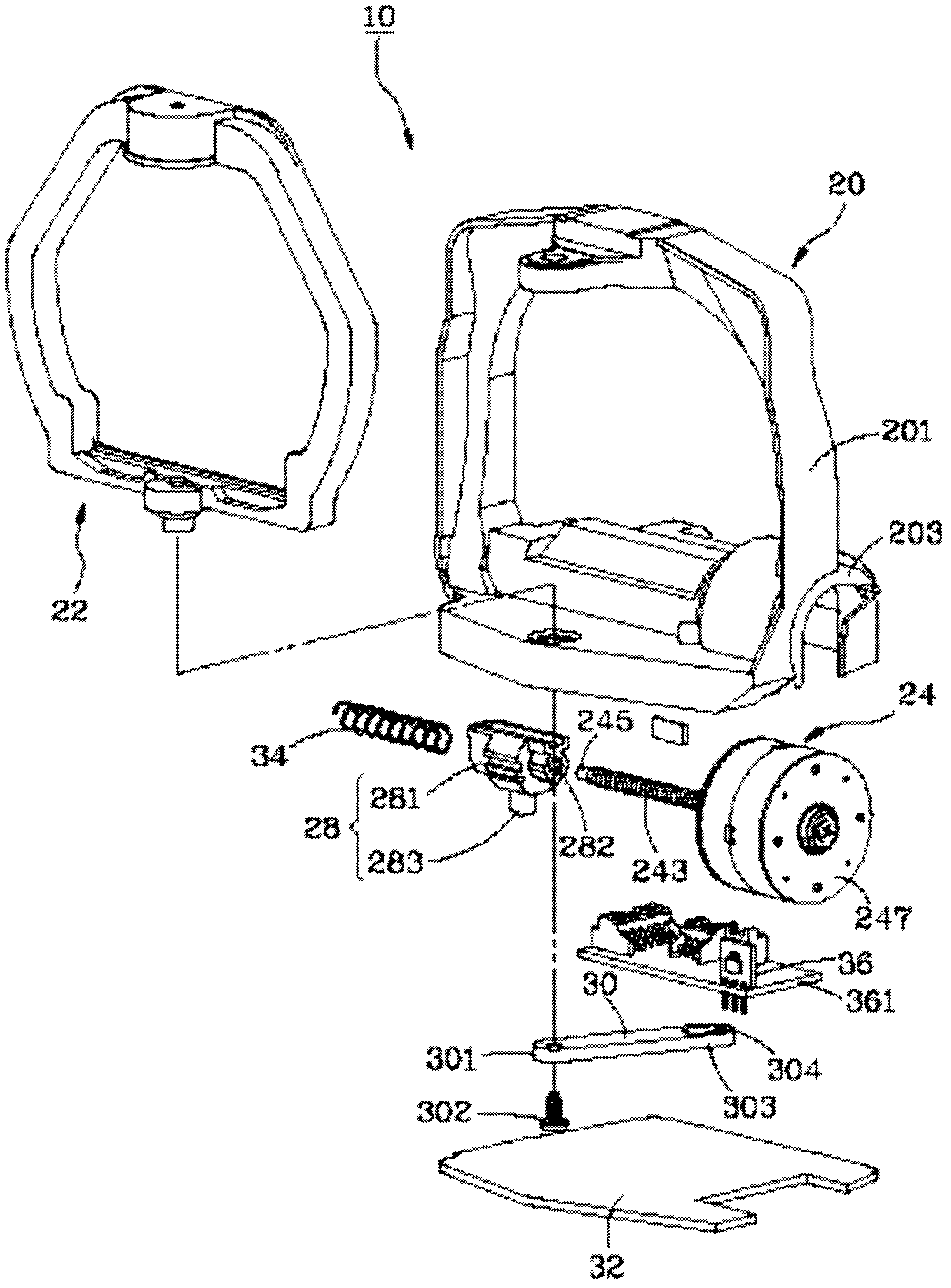

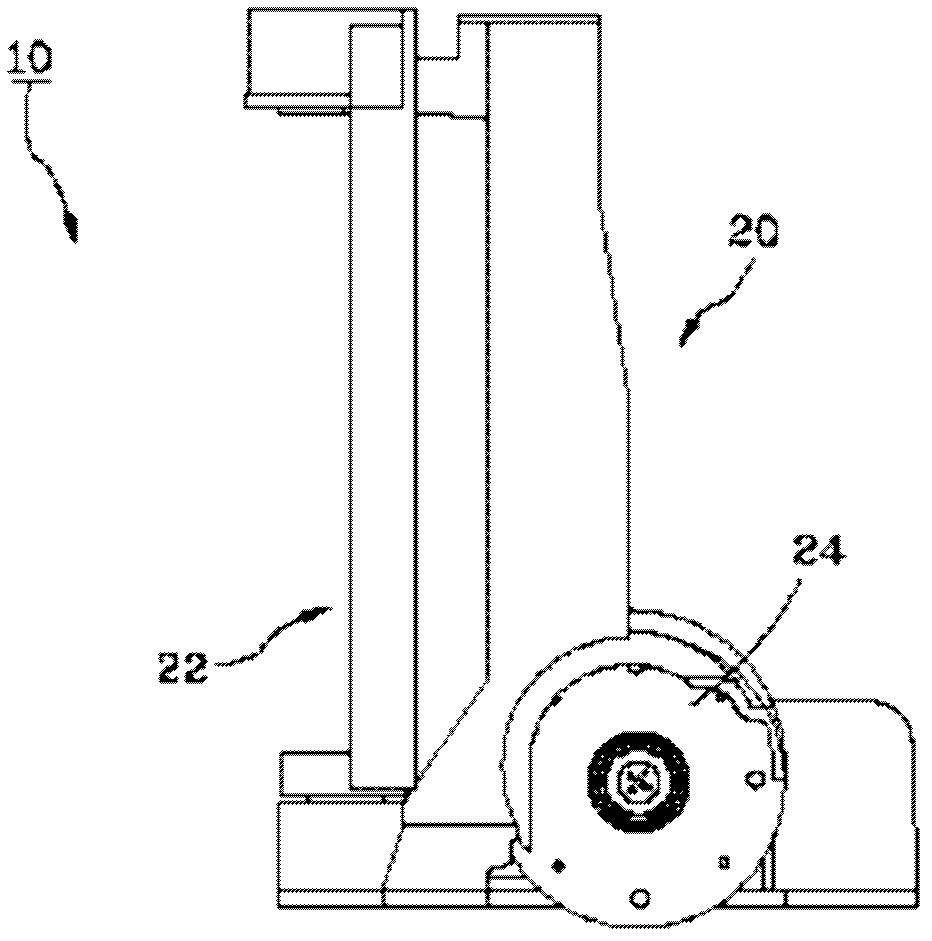

[0019] Such as Figure 1 to Figure 4 As shown, the vehicle light steering system driving device 10 provided by the first preferred embodiment of the present invention includes a base 20, a lamp support base 22, a stepping motor assembly 24, a moving part 28, a rotating rocker arm 30, A bottom cover 32 , a spring 34 and a position sensing component 36 .

[0020] The base 20 includes a frame portion 201, a motor accommodating portion 203 and a supporting portion 205 (such as Figure 4 As shown), the motor accommodating portion 203 and the supporting portion 205 are located at the bottom side of the frame portion 201 , and the supporting portion 205 has a fixing hole 206 .

[0021] The lamp support base 22 is pivotally connected to the frame portion 201 of the base 20 for setting a vehicle lamp (not shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com