Activated carbon production system

A technology of activated carbon production and feed inlet, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of increased labor force, high labor intensity, and increased production costs, so as to relieve pressure, avoid dust, and avoid materials landing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0023] It should be noted that, for the convenience of description, the following content does not distinguish between valves with the same function, and they are collectively referred to as valves.

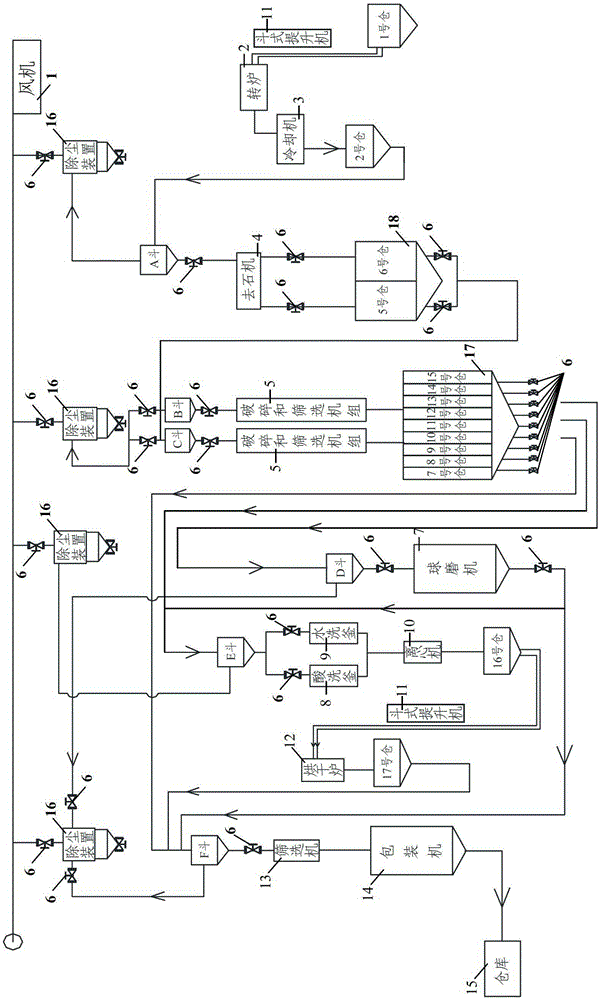

[0024] figure 1 Shown is a schematic structural diagram of an activated carbon production system in an embodiment of the present invention. Such as figure 1 As shown, the activated carbon production system in the embodiment of the present invention sequentially (here "sequential" is based on the production process of activated carbon) includes a stone remover 4, multiple sets of crushing and screening units 5, and subsequent processing The equipment, the screening machine 13 and the packaging machine 14 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com