Automated production device for Enshi Yulu and use method

A technology of production equipment and production process flow, which is applied in the field of Enshi Yulu automatic production equipment to achieve the effects of reducing labor costs, reducing labor intensity and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

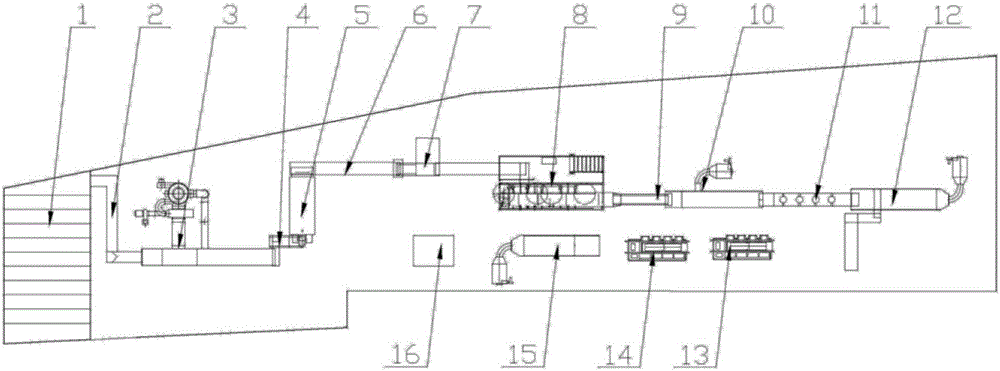

[0014]Embodiment 1: An automatic production device of Enshi Yulu, the production process is as follows: after the tea leaves are picked, they are placed in the green booth 1 for green processing for 16-20 hours until the moisture content of the tea leaves reaches 70-75%, and then the fresh leaves are transported by the fresh leaf conveyor 2. Send it to the air-heating greening machine 3; the air-heating machine 3 generates steam with a temperature of 120°C to act on the tea leaves. After continuous steaming for 70-73s, the first greening of the tea leaves is completed. The moisture content of the tea leaves is 75-77%, and 190 ℃ hot air for 123-126s to dehydrate the tea leaves. At this time, the water content of the tea leaves is 65-68%, and then the tea leaves are transported to the drum fixing machine 5 through the fixing conveyor 4; adjust the parameters of the drum fixing machine 5, and heat to make the temperature of the drum wall reach 190-200°C, after the tea leaves enter...

Embodiment 2

[0015] Embodiment 2: In the tea processing workshop of Enshi Qingjiang Tea Industry Co., Ltd., Enshi, Hubei Province. The Enshi Yulu automated continuous production line of the workshop was built in August 2011, and the layout was planned according to the production line described in the invention. After the tea leaves are picked, they are placed in the greening room 1 for greening processing for 16-20 hours until the moisture content of the tea leaves reaches 70-75%, and then the fresh leaf conveyor 2 transports them to the air-heating machine 3; the temperature of the air-heating machine 3 is 120 The steam at ℃ acts on the tea leaves, and after continuous steaming for 70-73s, the first greening of the tea leaves is completed, and the moisture content of the tea leaves is 75-77%, followed by hot air at 190°C, which lasts for 123-126s to dehydrate the tea leaves. At this time, the moisture content of the tea leaves is 65 -68%, and then transport the tea leaves to the roller fi...

Embodiment 3

[0016] Example 3: In the tea processing workshop of Enshi Qinxiyuan Tea Industry Development Co., Ltd., Enshi Prefecture, Hubei Province. The workshop introduced two Enshi Yulu automated continuous production lines in October 2013. The layout and implementation method are basically the same as those in Example 1. The difference is that the stall green room 1 in the production line can spread 4000 kg of fresh leaves; two steam heat fixers 3 and two roller degreening machines 5 are combined for degreening, and the production efficiency reaches 400 kg / hour; the dynamic dampening machine 7 can store 400 kg of degreen leaves; the kneading unit 8 performs tea kneading, and the production efficiency reaches 480 kg / hour; Fine kneading machine 14 and two No. two fine kneading machines 15 carry out shaping, and production efficiency reaches 400 kilograms / hour. Compared with other tea enterprises of the same scale, the labor force is reduced by more than half, the production capacity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com