Clamping holder for hollow silicon core

A hollow silicon core and clamping seat technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of increased silicon core fracture or collapse, inability to grow silicon core, and large crack impact, etc. Stability, ensure reduction yield, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention can be explained in more detail with reference to the following examples, but the present invention is not limited to these examples.

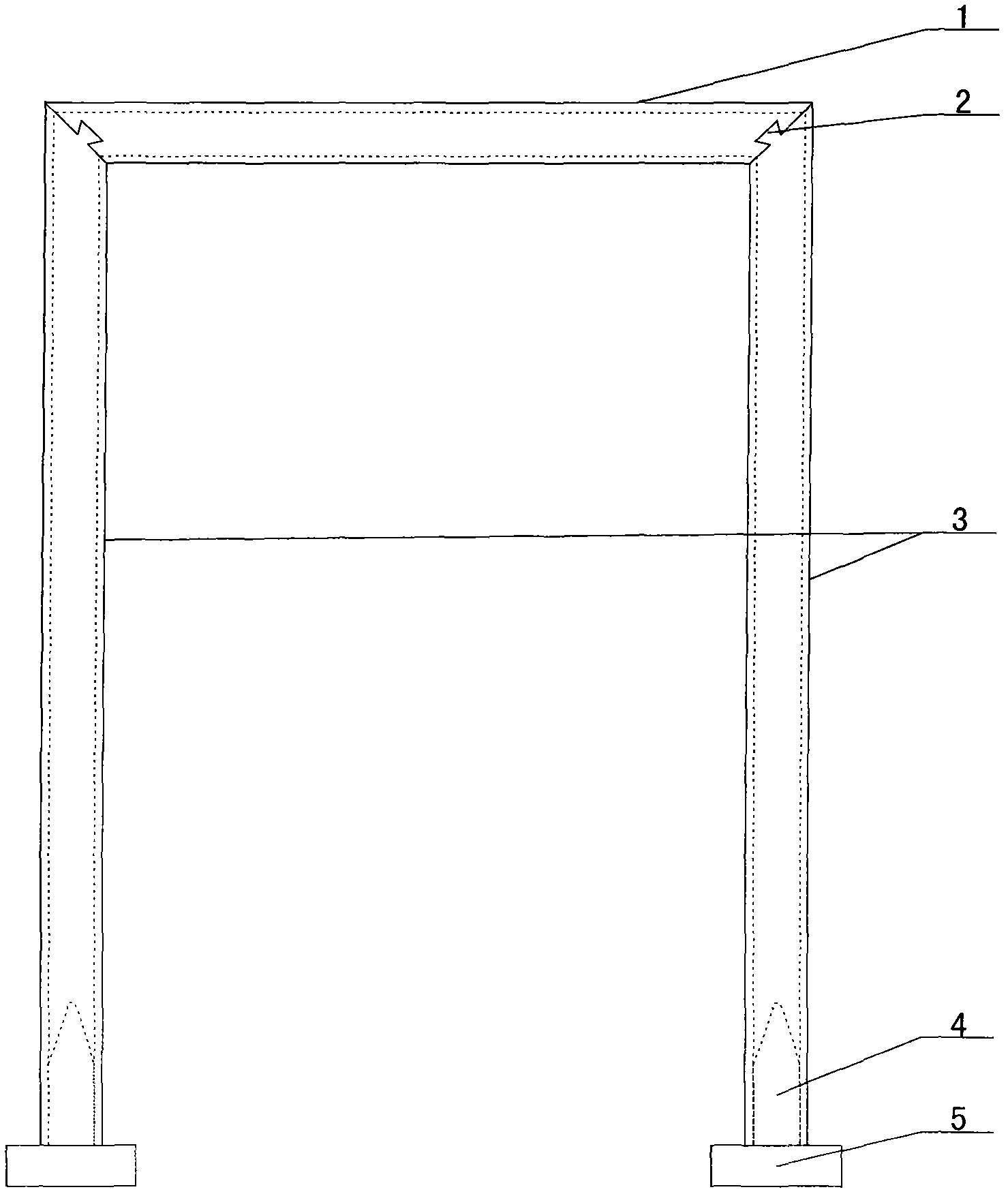

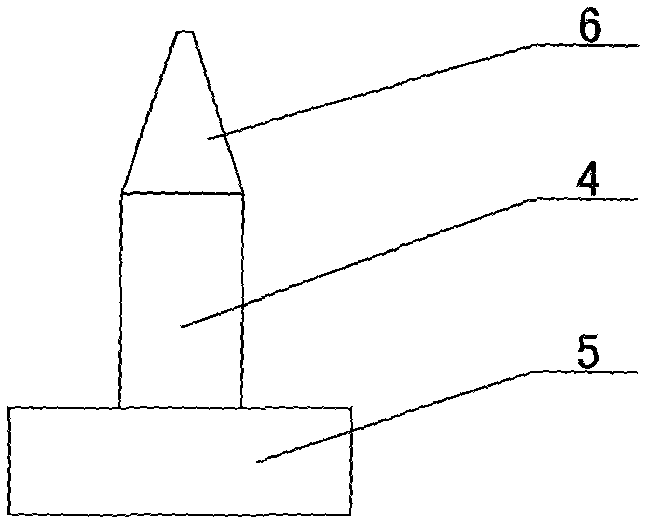

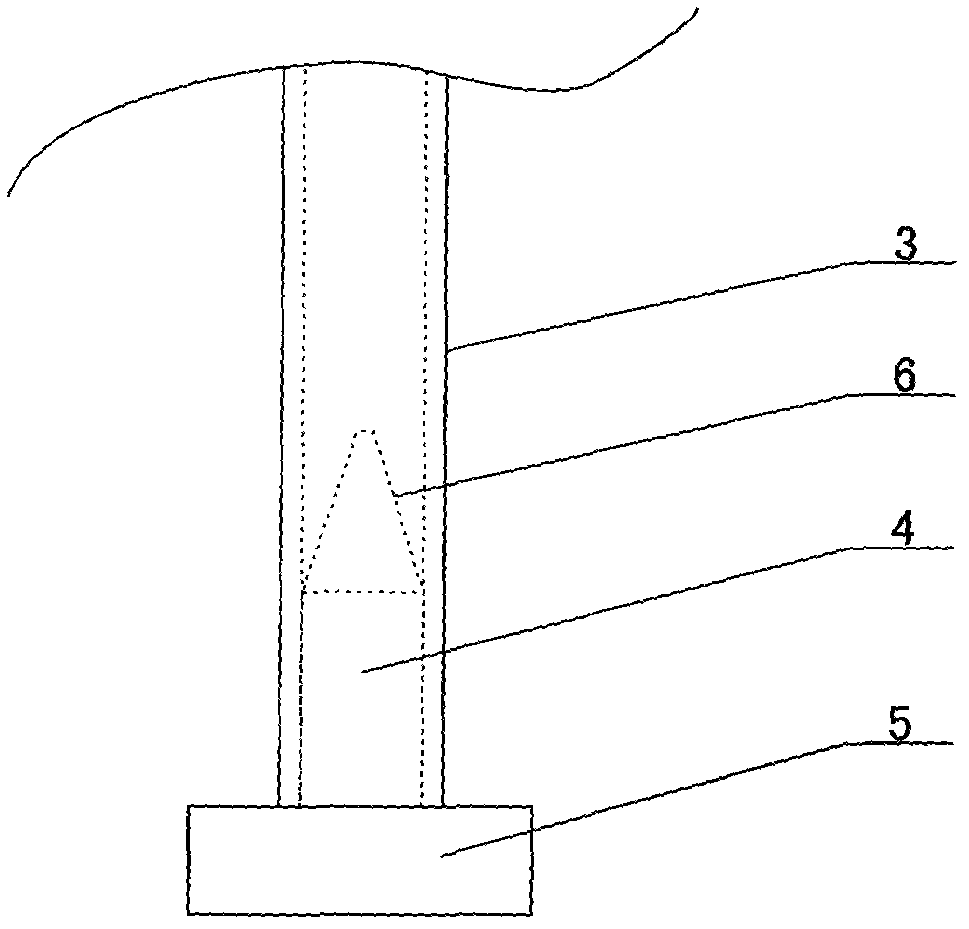

[0032] combined with Figure 1~3 In the clamping seat of the hollow silicon core, the two ends of a horizontal silicon core tube 1 are overlapped with the upper ends or upper parts of two vertical silicon core tubes 3, and the lower ends of the two vertical silicon core tubes 3 are connected to the two vertical silicon core tubes. Invention connection, the present invention connects the electrodes respectively to form a "∏"-shaped conductive circuit; wherein the horizontal silicon core tube 1 can also use a square silicon core or a solid silicon core as the horizontal silicon core, because the vertical silicon core tube 3 and the horizontal silicon core The overlapping of the overlapping joints does not belong to the protection scope of the present invention, so the present invention has no drawings and a detailed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com