Granularity homogenization method of refractory aggregate of various size fractions

A technology of refractory aggregate and particle size is applied in the production field of refractory aggregate particle size homogenization of various grades to achieve the effects of shortening mixing time, improving labor efficiency and improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

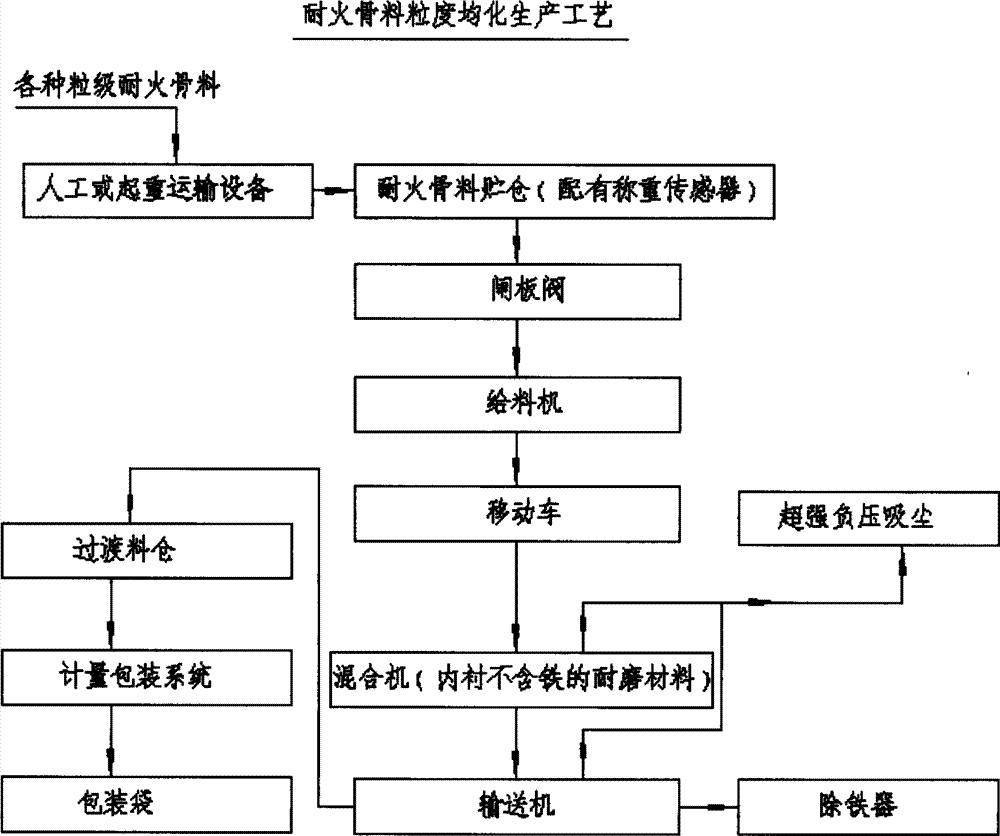

[0008] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0009] As shown in the figure, the refractory aggregate (15~14mm, 14~13mm, 13~12mm, 12~11mm, 11~10mm, 10~9mm, 9~8mm, 8~7mm, 7~6mm, 6~5mm, 5 ~4mm, 4~3mm, 3~2mm, 2~1mm, 1~0.5mm, 0.5~0mm) are sent into the storage bin manually or by lifting conveying equipment. Each silo is equipped with a weighing sensor, and the materials in the silo pass through the feeding equipment at the lower part of the silo according to the proportional requirements, and the amount of each material added is adjusted by the electrical control system. A certain proportion of refractory aggregate is sent into the mixer by a moving vehicle for pre-mixing. After a certain period of time, the pre-mixed refractory aggregate flows out through the outlet of the mixer and enters the conveying equipment for pre-mixing. When the mixed refractory aggregate passes through the conveying e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com