Device and method for uniform temperature of crucible when processing crystal material

A technology for processing crystals and crucibles, which is applied in the field of crucible heating, can solve the problems of crystal vibration, low yield of crystal rods, and quality degradation, and achieves the effects of overcoming crystal vibration, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

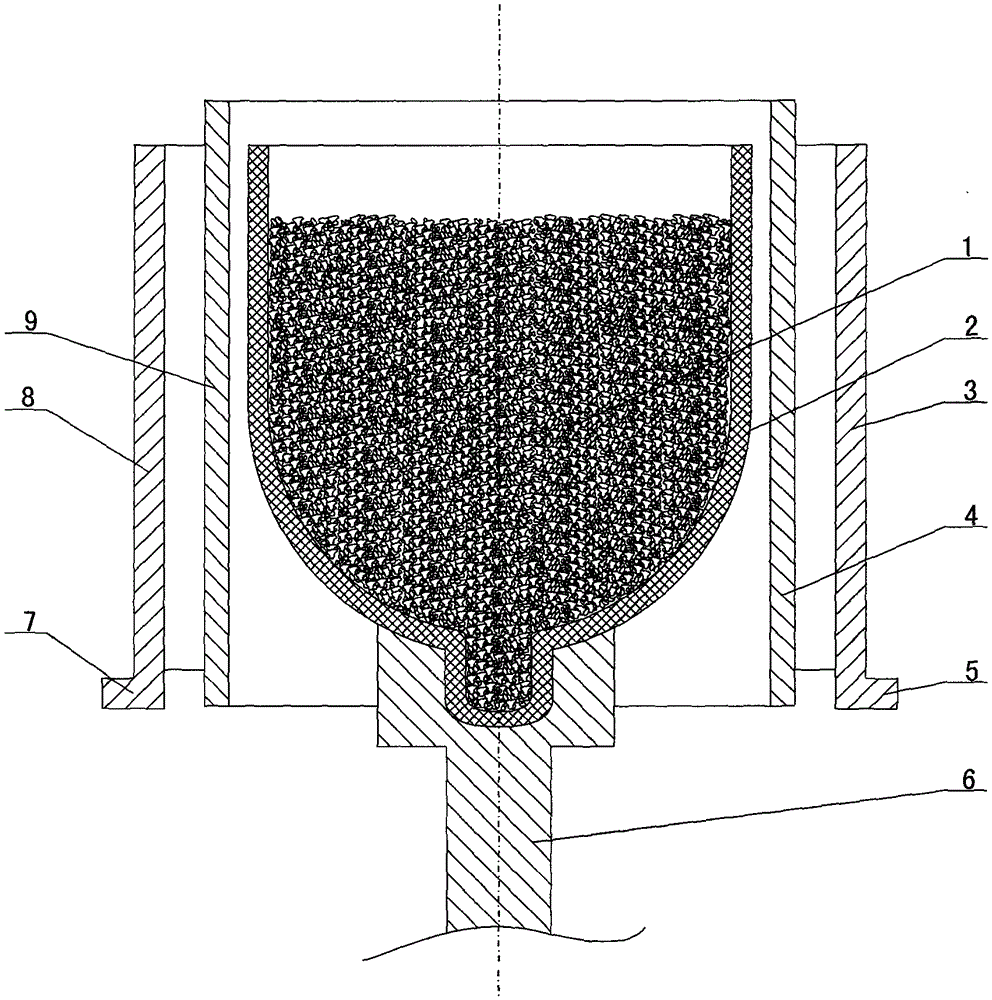

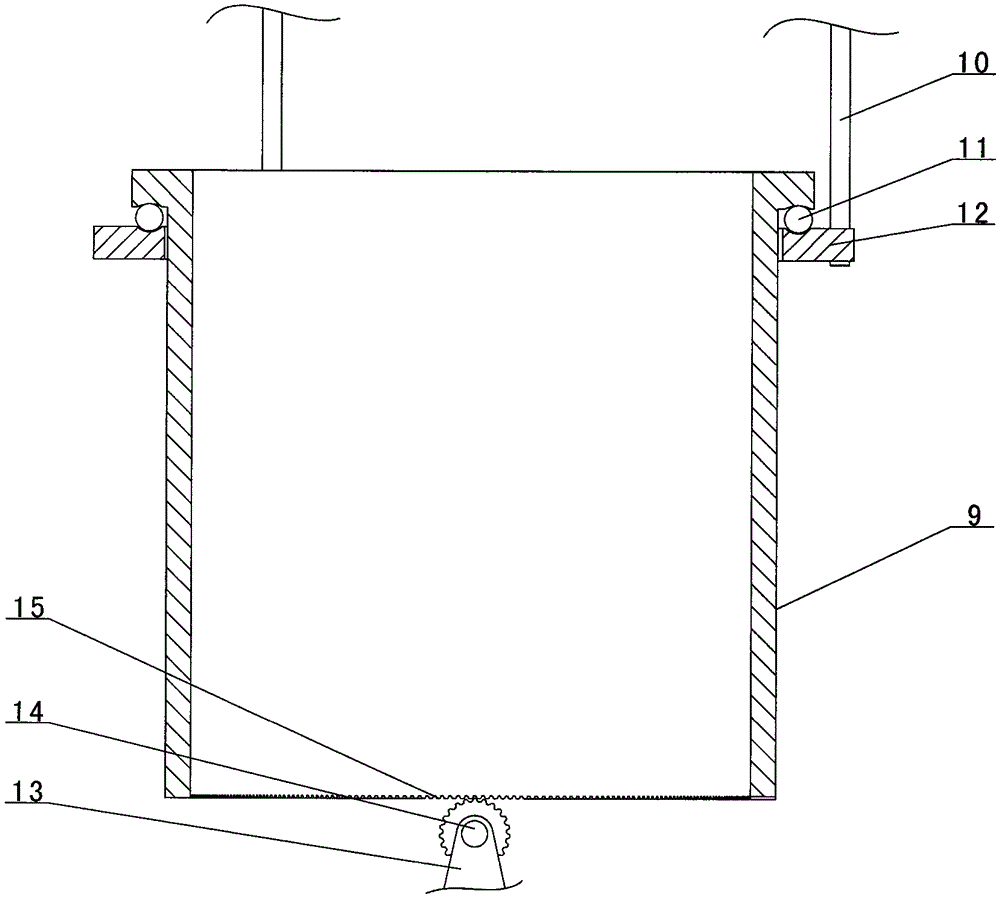

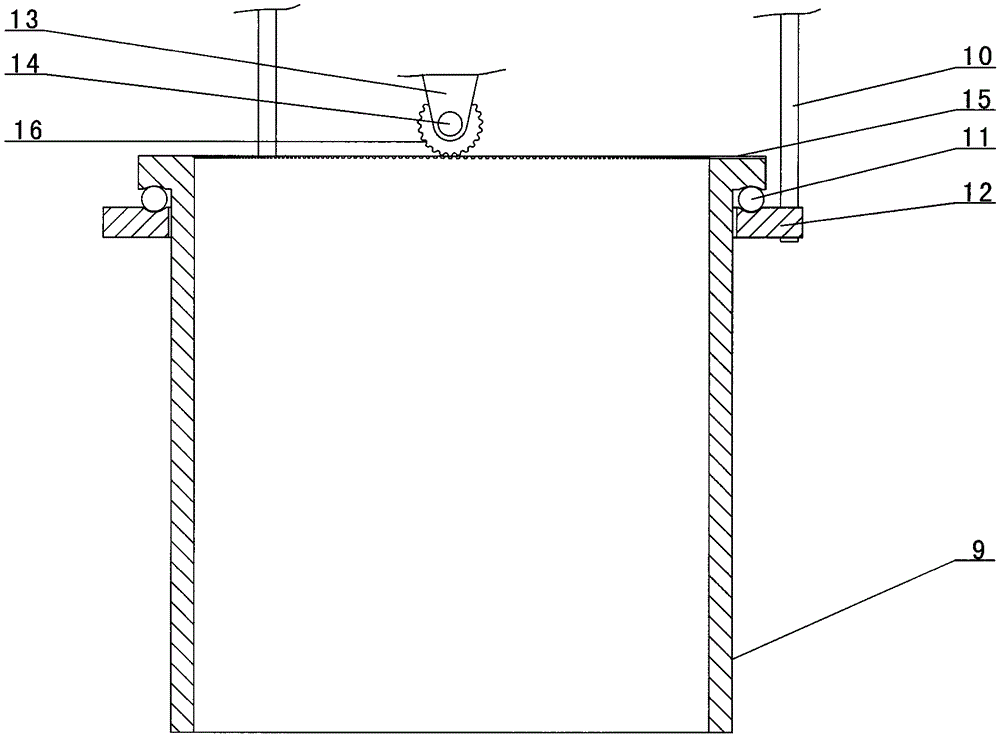

[0025] combined with figure 1 A temperature equalizing device for a crucible when processing crystal materials, including a crucible 2, a heating jacket and a support body 6, the crucible 2 is used to place the crystal material 1, and a heating jacket is arranged at intervals outside the crucible 2, and the heating jacket It is arranged concentrically with the crucible, and the two sides of the heating jacket are respectively connected with electrode A5 and electrode B7, wherein electrode A5 is connected with one side 3 of the heating jacket, and electrode B7 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com