Self-piercing nut

A technology for nuts and threaded holes, applied to nuts, threaded fasteners, connecting components, etc., can solve the problems of high cost, heavy load and deformation of the punching die 40, and achieve the effect of improving the life of the die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

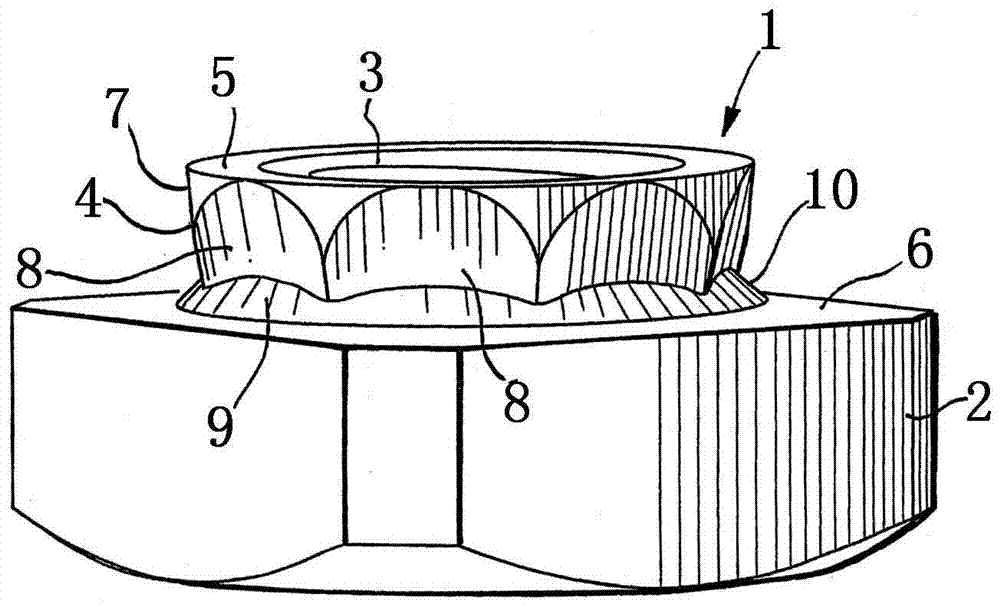

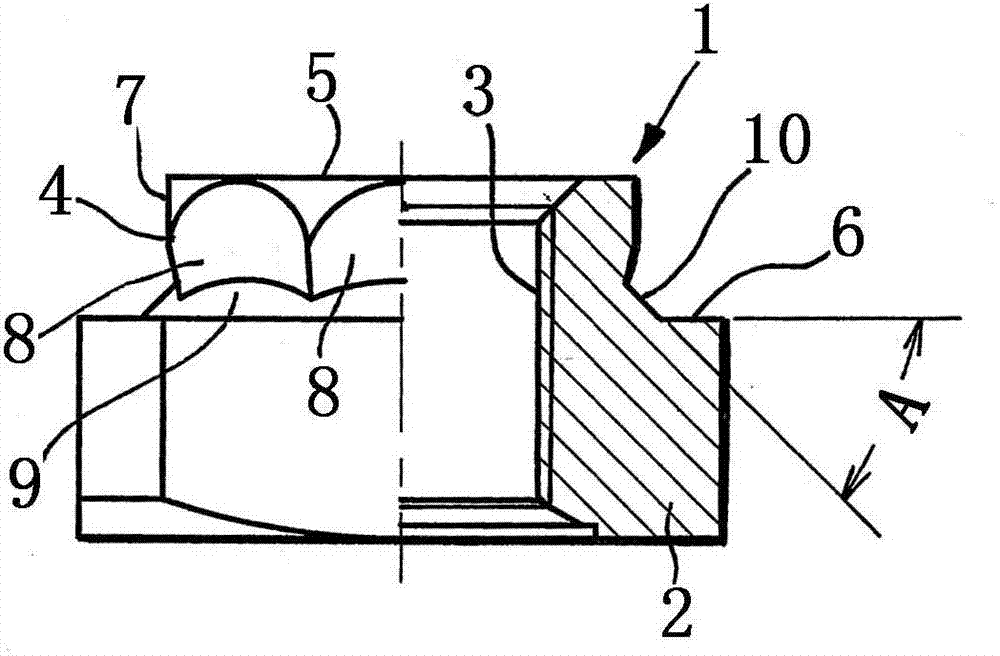

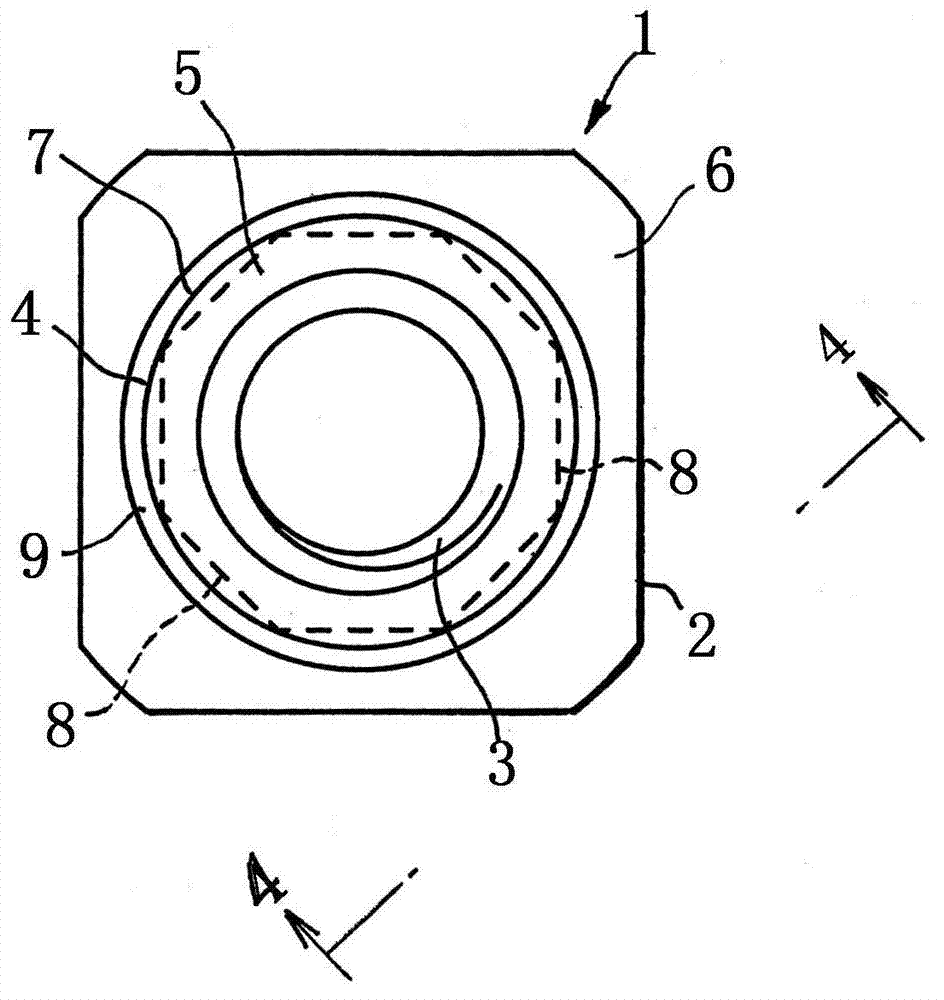

[0061] Figure 1 ~ Figure 4 Piercing nut 1 of Example 1 of the present invention is shown. The pierced nut 1 is manufactured by cold forging a common steel blank. The nut main body 2 is a rounded quadrilateral with four corners of the square nut cut off. The central part of the nut main body 2 including the threaded hole 3 protrudes. There is a cylindrical pilot part 4, and the end surface 5 of the cylindrical pilot part 4 functions as a punch for punching a metal plate. The piercing nut 1 has a fastening seat surface 6, and the fastening seat surface 6 Extends from the root of the pilot portion 4 to the outer peripheral edge of the nut main body 2 .

[0062] The peripheral edge of the end surface 5 of the pilot part 4 is formed in a circular shape, and the outer peripheral surface 7 of the pilot part 4 is composed of 6 to 12 (eight in the illustrated embodiment) flat surfaces 8 and is formed so as to gradually shrink from the end surface 5 toward the root. diameter of the p...

Embodiment 2

[0068] Such as Figure 9 ~ Figure 11 A piercing nut 15 according to Embodiment 2 of the present invention is shown. The piercing nut 15 basically has the same structure as the piercing nut 1 of the first embodiment, so the same reference numerals are assigned to the same structural parts and explanations are omitted. Next, structures different from the piercing nut 1 will be described.

[0069] Such as figure 2 As shown, the fastening seat surface 6 of the pierced nut 1 of the first embodiment is formed as a flat surface perpendicular to the axis of the nut body 2 . In contrast, as Figure 9 and Figure 11 As shown, the fastening seat surface 16 of the pierced nut 15 of the second embodiment is formed as an inclined surface that gradually becomes higher from the outer peripheral edge of the nut body 2 to the root of the pilot portion 4 . The inclination angle (B) with respect to the plane perpendicular to the axis of the nut main body 2 is preferably within a range of 5° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com