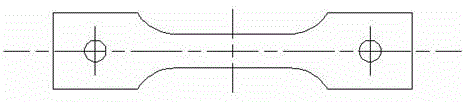

Special fixture for tensile testing of metal sheet or metal foil and method of use

A metal sheet and tensile test technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as eccentricity, thinning, and influence on test accuracy, and achieve the effect of ensuring self-neutrality and experiment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

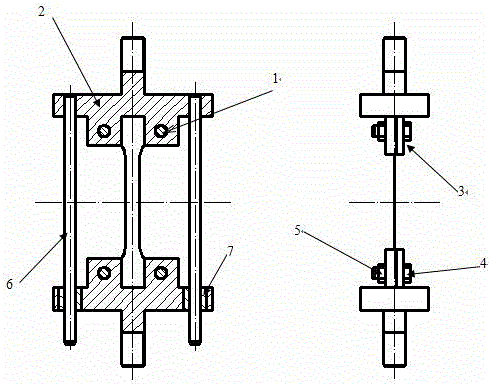

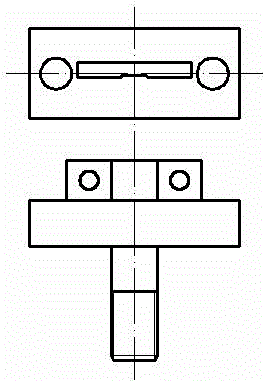

[0019] Depend on figure 2 As shown, the main components of the patent stamping riveting die of the present invention include: each upper and lower chuck, two sets of guide posts 6 and guide sleeves 7; It includes "T" type clamping element 2, small clamping element 3, two pairs of bolts 4 and nuts 5; the structure of the lower chuck is the same as that of the upper chuck. The assembly relationship is: the upper and lower "T"-shaped clamping elements 2 are respectively connected to the base of the tensile testing machine through threaded holes 1, and the guide sleeve 7 and the lower "T"-shaped clamping elements are interference fit. There is an interference fit between the guide post 6 and the upper "T"-shaped clamping element 2, and a clearance fit between the guide post 6 and the guide sleeve 7.

[0020] The specific assembly process is: first install the guide sleeve with the lower chuck, install the guide post with the upper chuck, and then install the guide sleeve and gui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com