An acid resistance test system for fracturing proppants

A technology of fracturing proppant and tester, which is applied in the field of proppant, and can solve the problems of not providing simulated reservoir environment equipment, temperature and pressure cannot be effectively controlled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

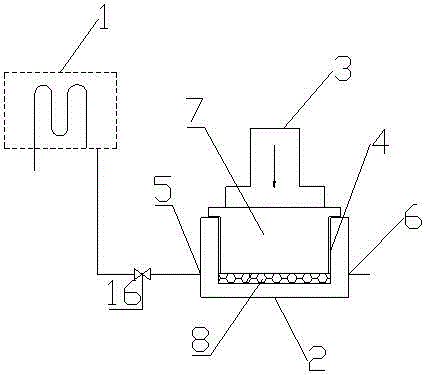

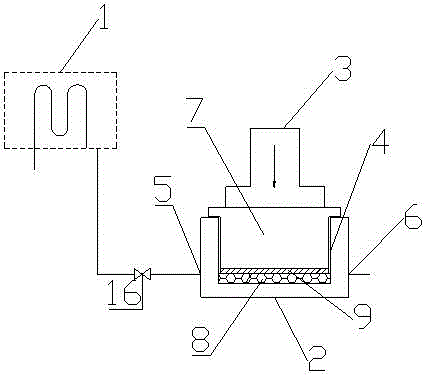

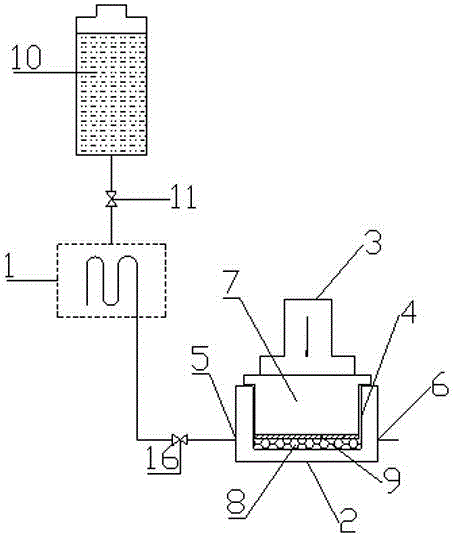

[0029] The acid resistance test system for fracturing proppant described in the present invention is as figure 1 As shown, it includes an acid preheater 1, a tester 2 and a press 3. The acid preheater 1 is provided with an inlet and an outlet, and the positions of the inlet and outlet of the acid preheater 1 can be selected according to actual needs. , the press 3 is a commercially available press, hydraulic press and hydraulic press, etc., which can apply pressure; the tester 2 has a housing and an open material chamber 4 arranged in the housing. The housing is provided with a liquid inlet 5 and a liquid outlet 6, and the liquid inlet 5 and the liquid outlet 6 are respectively connected with the material holding chamber 4; the setting of the liquid inlet 5 and the liquid outlet 6 The location can be selected according to actual needs. In this embodiment, the liquid inlet 5 and the liquid outlet 6 are arranged on the opposite side walls of the tester 2 and are close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com