Thin film structure of solar cell absorbing layer and manufacturing method thereof

A technology of solar cells and thin film structures, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of reduced light absorption range, inability to obtain solar cell absorption layers, etc., to avoid the reduction of absorption range and improve efficiency , the effect of Canon gap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the structural characteristics and forming method of the thin film structure of the absorption layer of the CIGS solar cell provided by the present invention will be described with reference to the accompanying drawings.

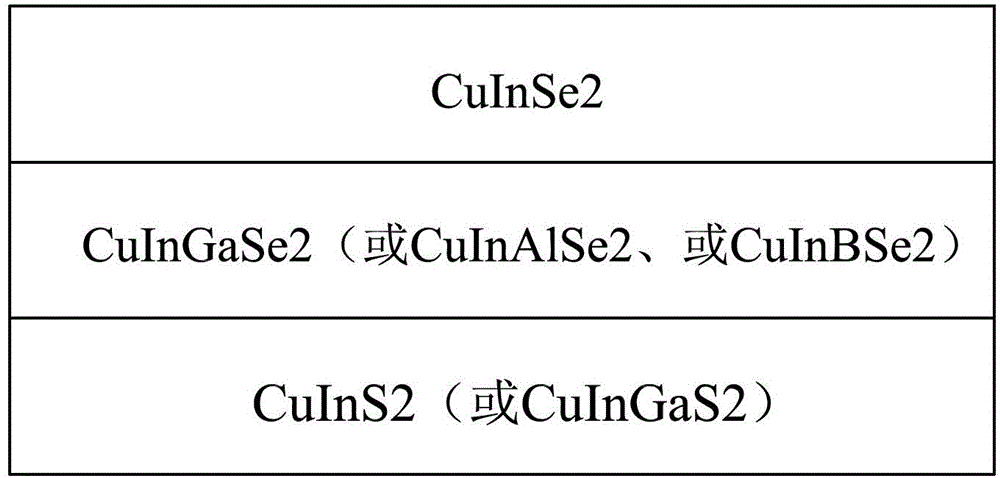

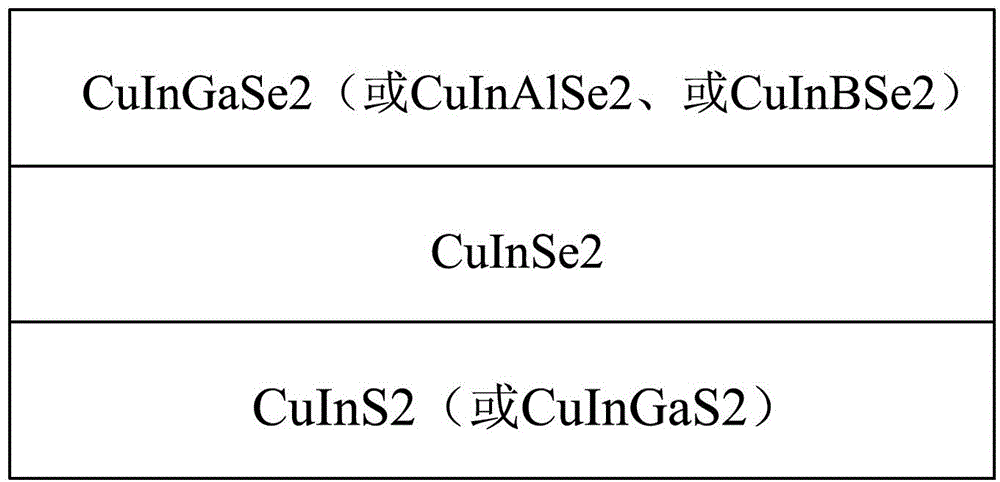

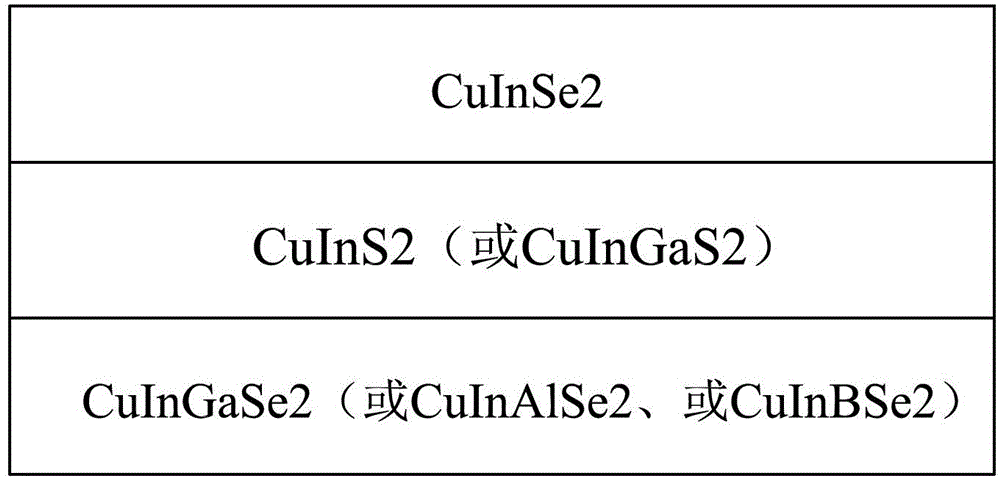

[0033] The thin film structure of the absorption layer of the copper indium gallium selenide solar cell, such as figure 1 shown, including sequentially stacked CuInSe 2 Thin film layer, CuInGaSe 2 thin film layer (or CuInAlSe 2 Thin film layer, or CuInBSe 2 thin film layer) and CuInS 2 thin film layer (or CuInGaS 2 film layer), as for the buffer, conduction, electrode layer and substrate required to be provided on both sides of the absorbing layer film, they are all the same as the prior art, so they are not drawn in the drawings.

[0034] And the manufacturing method of the absorption layer film structure of the copper indium gallium selenide solar cell comprises the following steps:

[0035] Step 1, preparing the CuInSe 2 Thin fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com