Sealed letter making device and envelope paper

A technology for making a device and an envelope, which is applied to the device for sealing the bag, the device for putting documents into the bag, and the bag-making operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

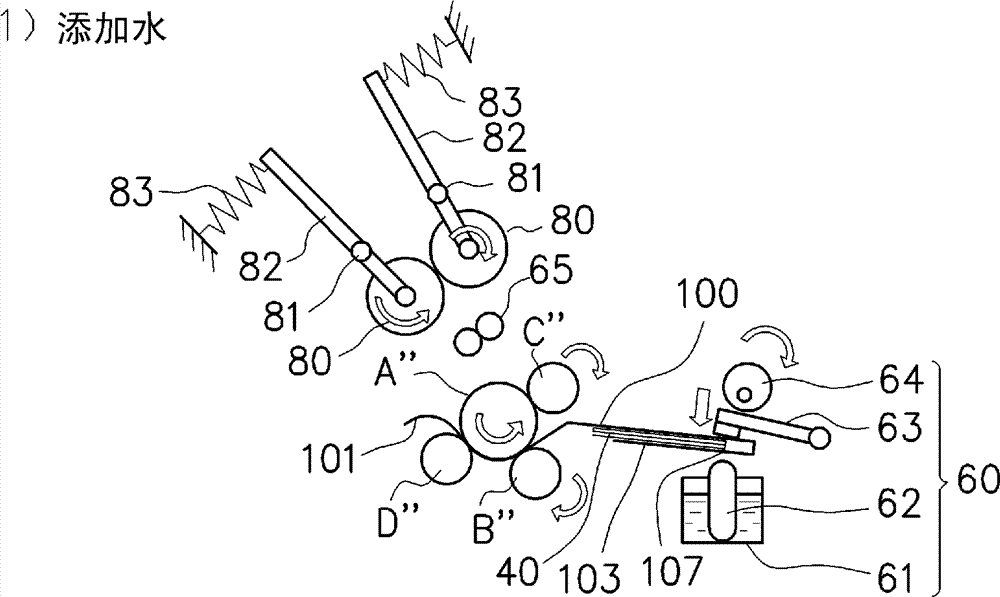

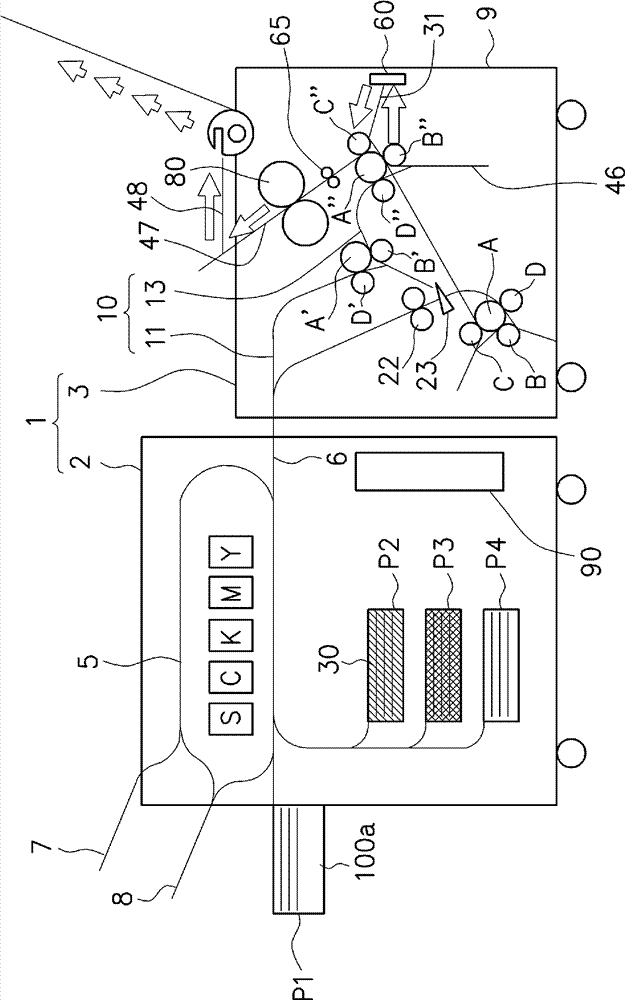

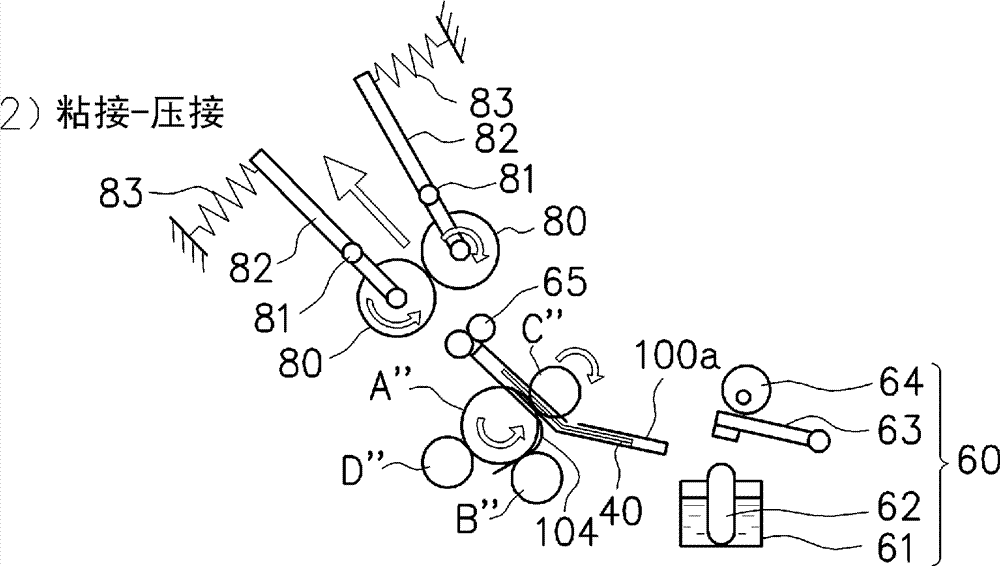

[0150] 2. The second embodiment ( Figure 14 ~ Figure 17 )

[0151] Figure 14 It is a figure showing the surface (the side on which the addressee's name is printed) of the envelope paper 200 used in this embodiment, figure 2 It is a figure which shows the back side. The envelope paper 200 is a rectangular paper in which three paper pieces, namely a first paper piece 201 , a second paper piece 202 , and a third paper piece 203 , are connected by creases.

[0152] Such as Figure 14 As shown, the surface of the first sheet of paper 201 is equivalent to the back of the envelope, and the sender's name, address, etc. are printed. In addition, two perforation lines 204 are formed on the first sheet 201 from the long side parallel to the crease to both edges in the width direction. What is necessary is just to peel off the center part of the 1st paper sheet 201 along this perforation line 204, when opening the sealed envelope. The surface of the second sheet 202 corresponds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com