Sealing structure of electric kettle

A technology of sealing structure and electric kettle, which is applied in the sealing of engines, utensils for boiling water, cooking utensils, etc., can solve the problems of poor sealing, high cost, and difficult assembly, so as to prevent poor sealing, improve quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

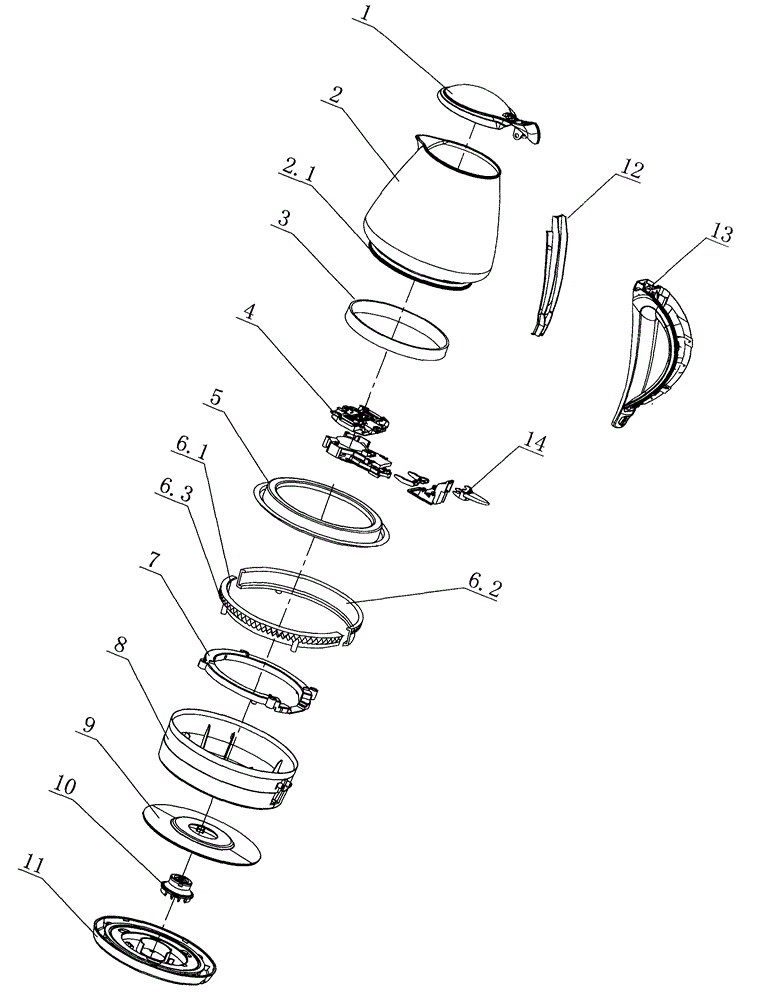

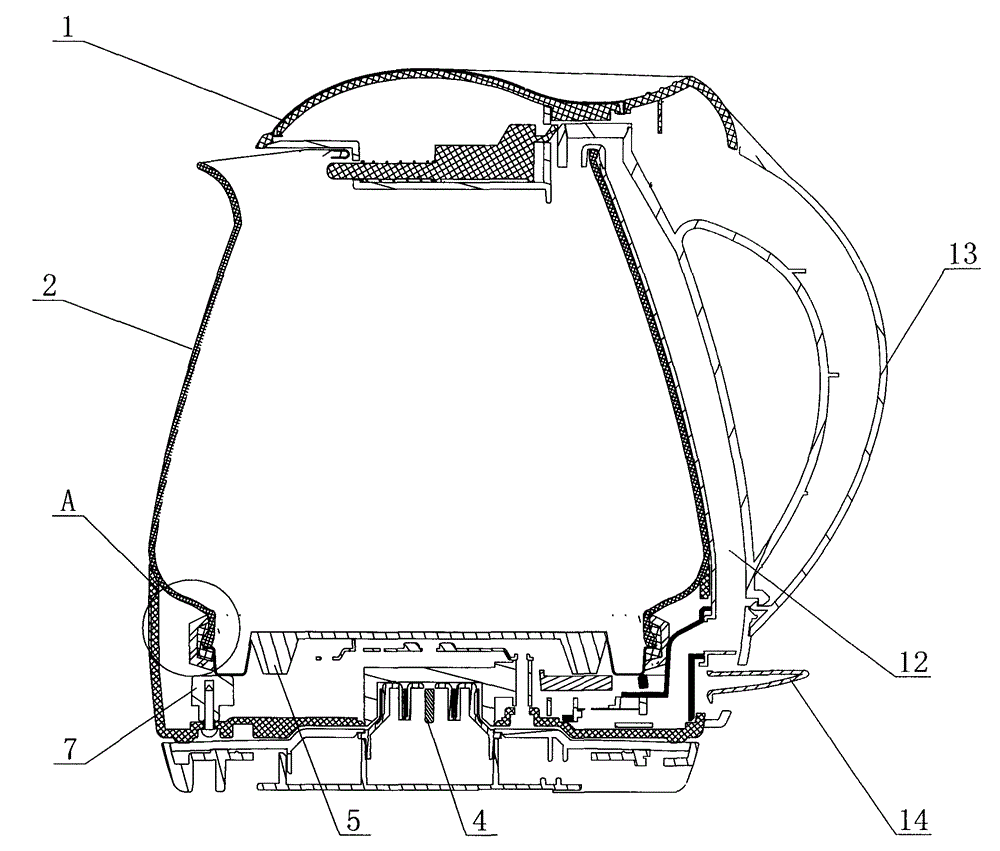

[0023] see Figure 1-Figure 4 , the sealed structure of the electric kettle includes a main body 2 with a handle 13 and its bottom cover 8, the handle 13 and the main body 2 are separated, and a steam channel 12 is arranged between the handle 13 and the main body 2, and the steam channel 12 communicates with the inner cavity of the main body 2, and the material of the main body 2 is glass. The handle 13 is provided with a cover body 1 hingedly fixed thereto, and the cover body 1 is rotatably connected with the main body 2 . A heating element 5 is arranged in the main body 2, and the heating element 5 is a heating plate. The bottom cover 8 is provided with a thermostat assembly 4 electrically connected to the heating element 5 , a switch button 14 and a power connection assembly. The power connection assembly is movably connected with the bottom cover 8, and the power connection assembly is assembled by the power supply upper cover 9 and the power supply lower cover 11. A co...

no. 2 example

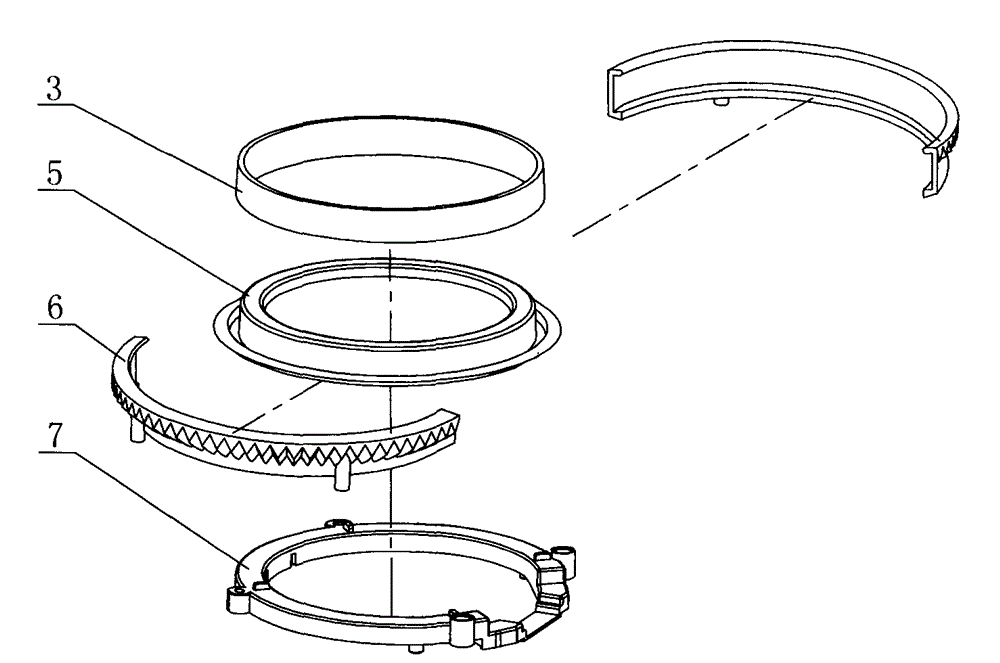

[0027] see Figure 5-Figure 6 , the silicone sealing ring 3 is arranged on the opening of the body and the place where the heating element is connected for sealing connection, the opening 2.1 of the body 2 is inserted into the heating element 5, or the opening of the heating element 5 is inserted into the opening 2.1 of the body, the body The connection between the opening and the heating element is set as an outer convex surface or a body opening 2.1 and the heating element 5 are combined to form an outer convex surface and a plane, and the silicone sealing ring is wrapped or covered on the lower part of the body; the outer wall of the silicone sealing ring and the shrinkage fixing piece are against each other , the cross-section of the main body opening is linear, bent or inclined, and the silicone sealing ring 3 is wrapped in the lower part of the main body 2, so as to realize the extrusion deformation sealing effect of the main body 2 and the heating element 5, and further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com