Single stand column plane coordinate mechanical arm of box filler

A technology of plane coordinates and robotic arms, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of cumbersome installation and adjustment, complex structure of robotic arms, and high production costs, so as to save time for replacement and installation and improve production efficiency , Simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and the best embodiments.

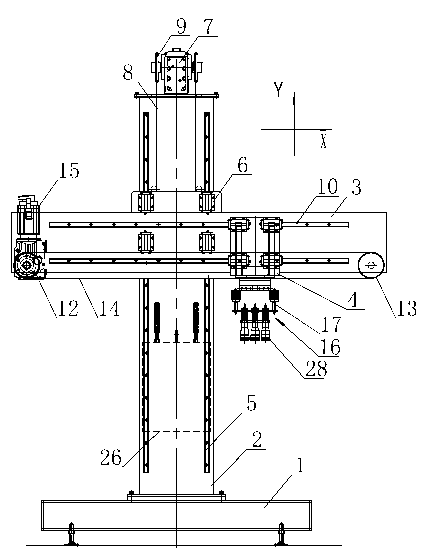

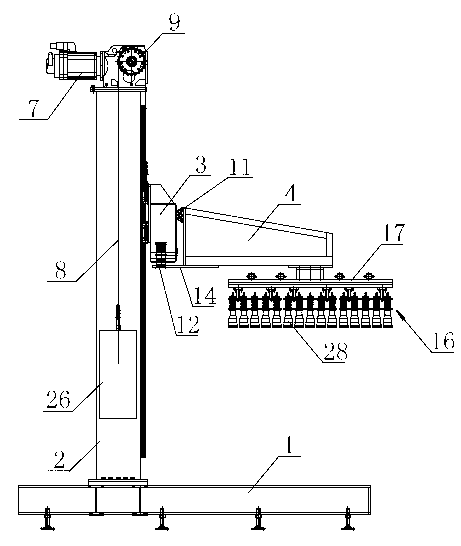

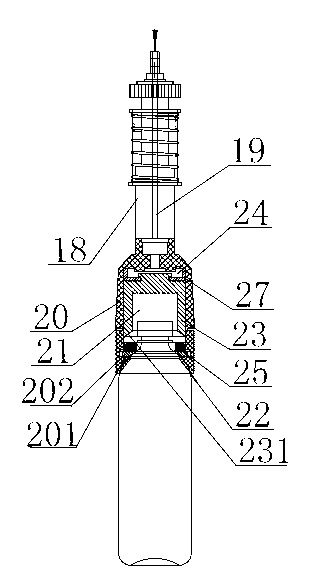

[0014] like figure 1 , figure 2 , image 3 As shown, the single column plane coordinate mechanical arm on the case packing machine includes a base 1, a support column 2 is fixedly installed on the base 1, a horizontal beam 3 is arranged on the support column 2, and a bottle grasping robot arm 4 is arranged on the horizontal beam 3. The support column 2, the horizontal beam 3, and the bottle-grabbing mechanical arm 4 are perpendicular to each other in pairs, wherein the connection structure between the support column 2 and the horizontal beam 3 includes: the support column 2 is provided with a lifting guide rail 5, and the horizontal beam 3 is provided with a The lifting slider 6 used in conjunction with the lifting guide rail 5 is provided with a lifting drive device on the supporting column 2. The structure of the lifting driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com