Five-composite rubber extrusion head

A technology of extruder head and compound rubber, applied in the field of rubber machinery, can solve problems such as need to redesign, achieve the effect of optimized layout, reduced manufacturing and processing costs, good rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

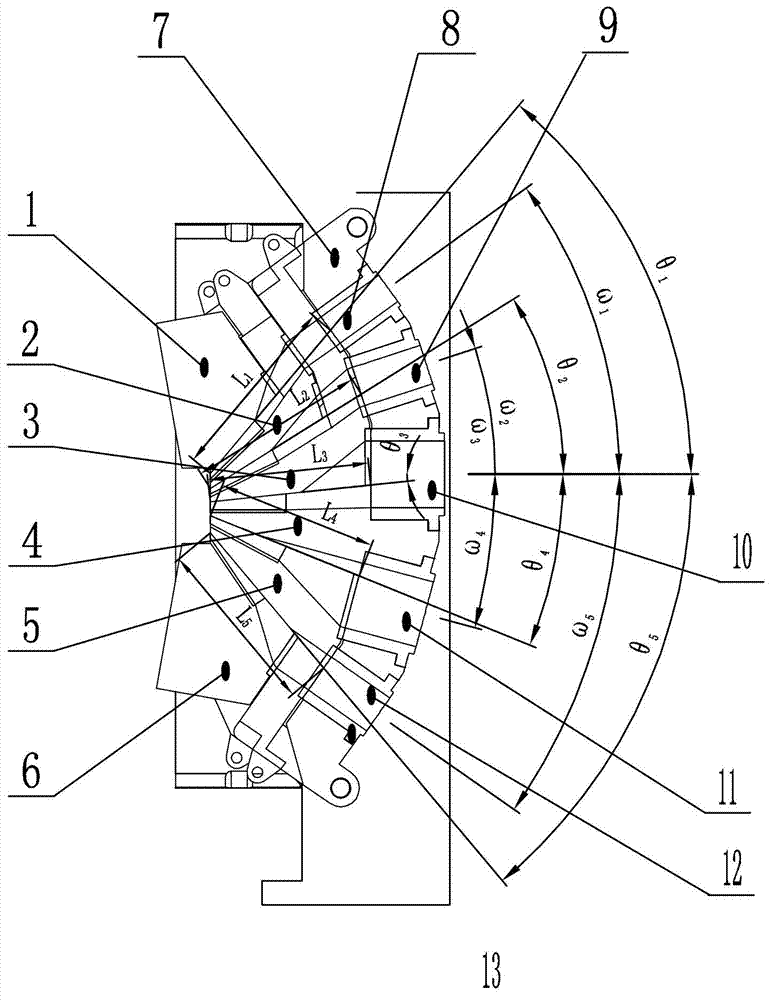

[0029] In this example, a five-compound rubber extruder unit equipped with five rubber extruders is taken as an example. The five rubber extruders are 120, 150, 250, 250, and 150 respectively, that is, the extruder screw diameter They are 120mm, 150mm, 250mm, 250mm, and 150mm respectively.

[0030] figure 1 Shown in this example is the five compound rubber extruder head of the five compound rubber extruder unit, including upper die 1, upper middle die 1, upper middle die 2 3, middle die 4, lower middle die 5, and lower die 6. The middle mold 4 and the mold base 7 are connected as a whole, the upper middle mold 4 is followed by upper middle mold two 3, upper middle mold one 2, and upper mold 1, upper middle mold two 3, upper middle mold 1, 2, and upper mold 1 The hinge shaft is hinged with the middle mold 4. Below the middle mold 4 are the lower middle mold 5 and the lower mold 6 in sequence, and the middle and lower molds 5 and 6 are hinged with the middle mold 4 through the low...

Embodiment 2

[0040] This example is structured as figure 1 As shown, it is similar to Embodiment 1, except that the installation angles of each extrusion port and parting surface of the mold body and the length of each runner cavity are different from Embodiment 1.

[0041] The installation angle of each extrusion port in this example is: the included angle ω between the axis of the upper die extrusion port 8 and the horizontal plane 1 Is 45°, the angle between the axis of the upper and middle die 9 and the horizontal plane ω 2 Is 20°, the included angle ω between the axis of the middle die extrusion port 10 and the horizontal plane 3 Is -5°, the included angle ω between the axis of the lower middle die extrusion port 11 and the horizontal plane 4 Is -20°, the angle between the axis of the lower die extrusion port 12 and the horizontal plane ω 5 Is -45°.

[0042] The angle between the parting surface and the horizontal plane between the upper mold 1 and the upper middle mold 2 in this example 1 ...

Embodiment 3

[0045] This example is structured as figure 1 As shown, it is similar to Embodiment 1, except that the installation angles of each extrusion port and parting surface of the mold body and the length of each runner cavity are different from Embodiment 1.

[0046] The installation angle of each extrusion port in this example is: the included angle ω between the axis of the upper die extrusion port 8 and the horizontal plane 1 Is 34°, the angle between the axis of the upper and middle die extrusion 9 and the horizontal plane ω 2 16°, the included angle ω between the axis of the middle die extrusion port 10 and the horizontal plane 3 2°, the included angle ω between the axis of the lower middle die extrusion port 11 and the horizontal plane 4 Is -13°, the angle ω between the axis of the lower die extrusion port 12 and the horizontal plane 5 Is -33°.

[0047] The angle between the parting surface and the horizontal plane between the upper mold 1 and the upper middle mold 2 in this example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com