Pneumatic sealing assembly of molding drum transmission box and method thereof

A kind of pneumatic sealing and transmission sealing technology, which is applied in the direction of engine sealing, engine components, other household appliances, etc., can solve the problems of inability to achieve precise sealing, affecting the maneuverability of the main shaft, unstable main shaft air pressure, etc., to improve the accuracy of transmission. The effect of improved performance and drive performance, and easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

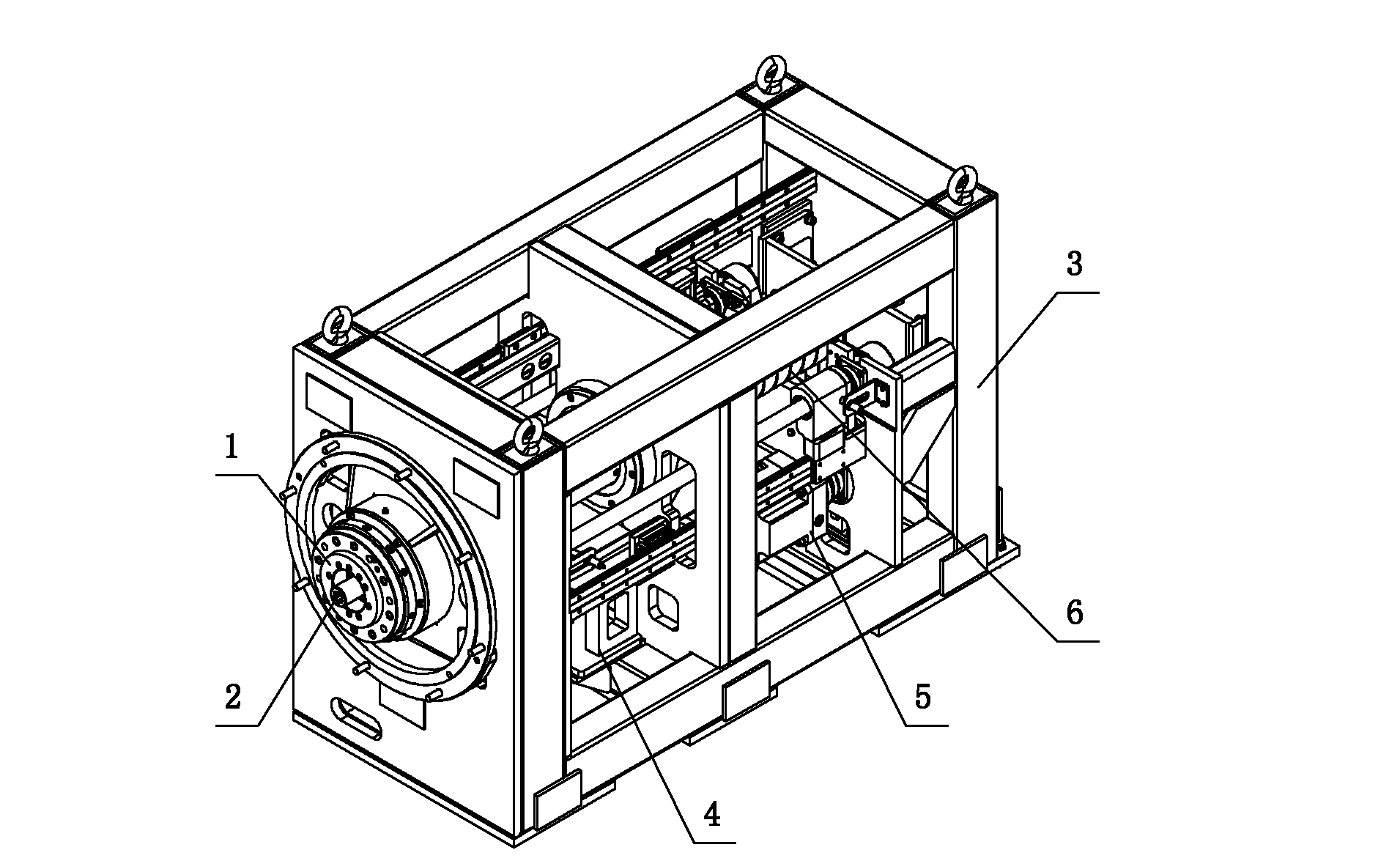

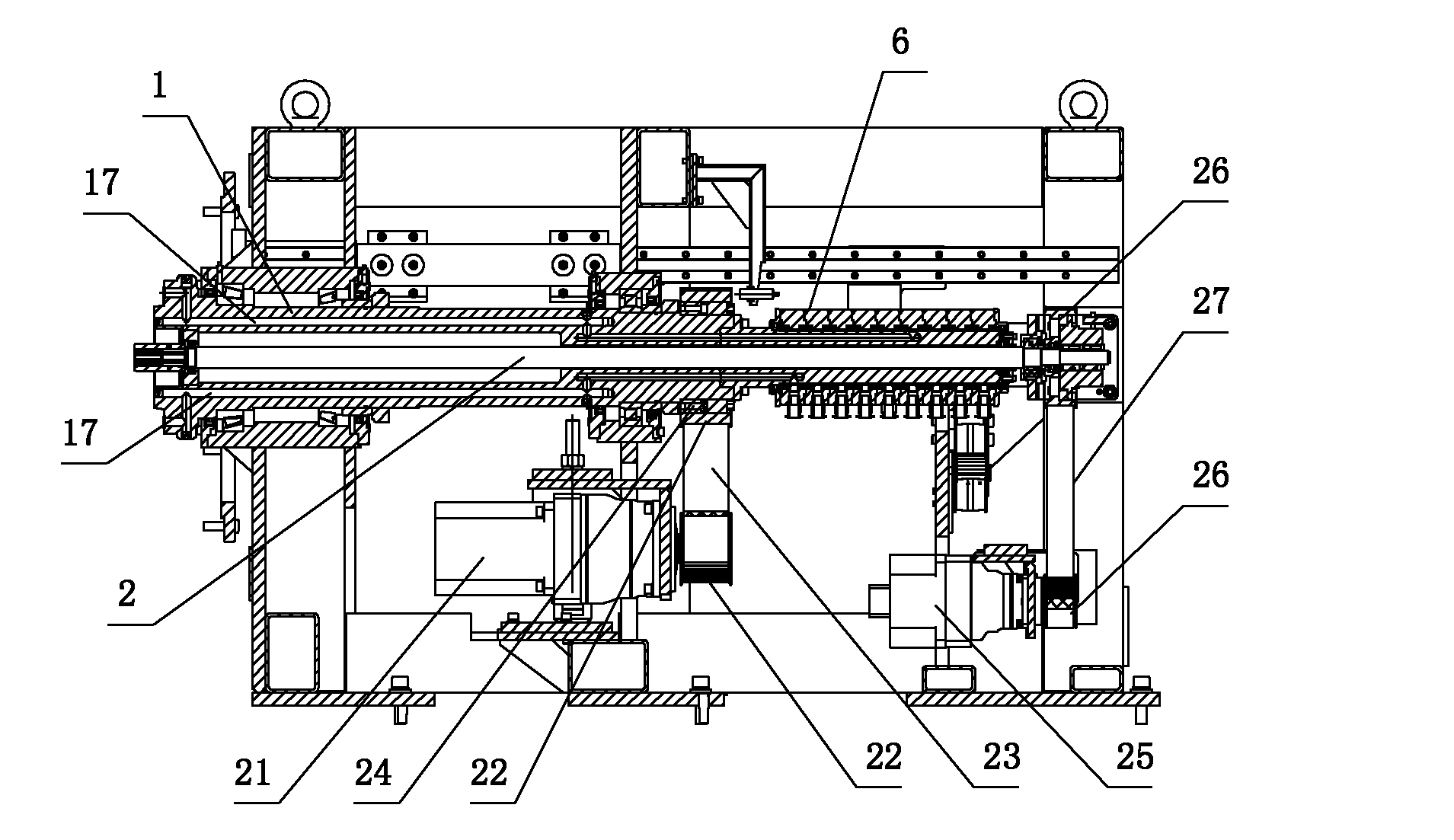

[0043] Example 1, such as figure 1 and figure 2 As shown, the pneumatic sealing assembly of the forming drum transmission box is arranged inside the transmission box 3, the outer end of the pneumatic sealing assembly 6 is connected to the main shaft 1, and the main shaft air passage 17 inside the main shaft 1 is connected to the air passage inside the pneumatic sealing assembly 6. Pass;

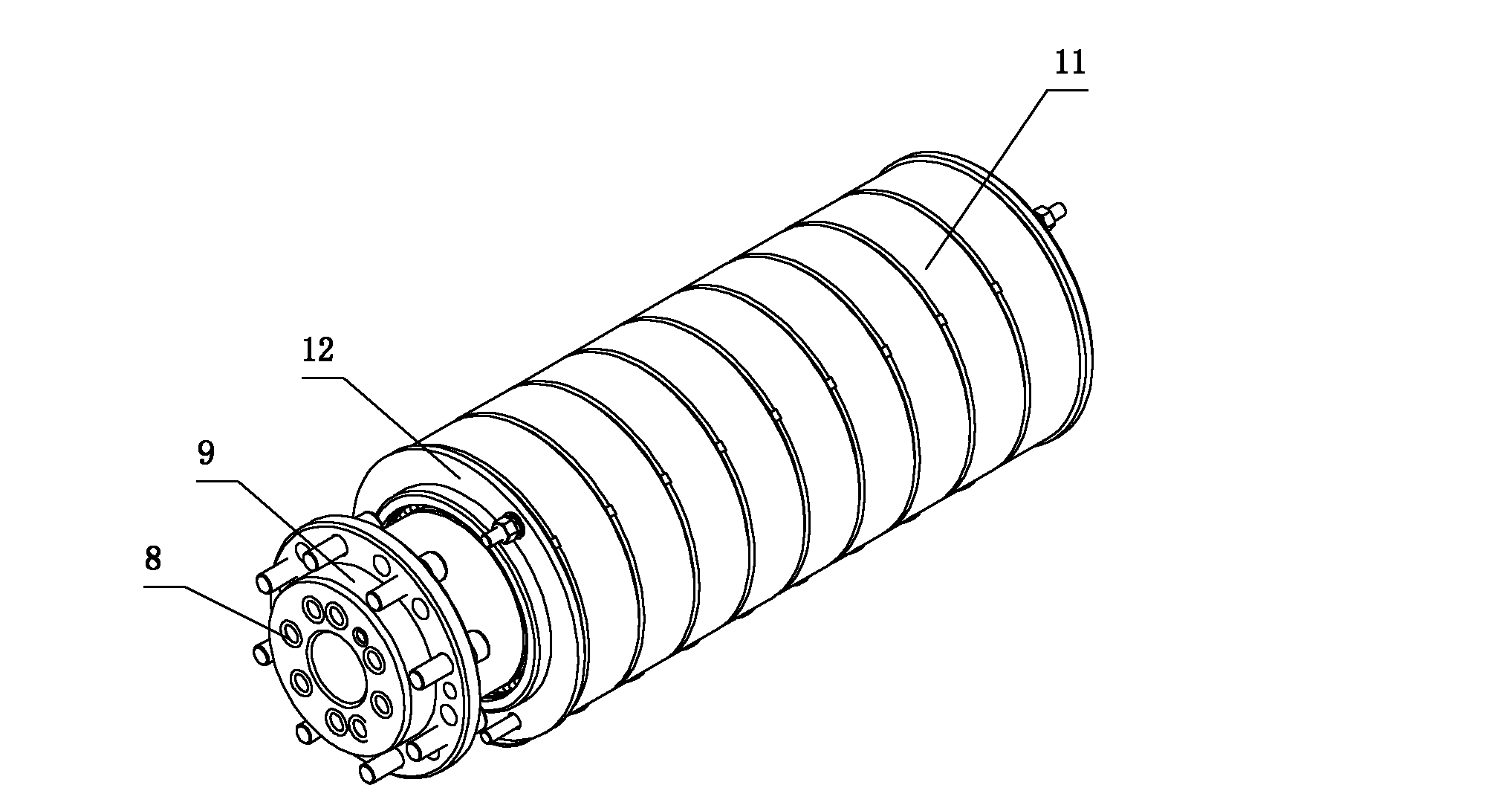

[0044] The pneumatic seal assembly 6 is sheathed on the outer diameter of the inner shaft 2 , and the radial connection between the inner end of the pneumatic seal assembly 6 and the radial direction of the inner shaft 2 is carried out through a rolling bearing 7 and sealed.

[0045] Wherein, the inner shaft 2 carrying the forming drum lock block is sleeved on the inner diameter of the main shaft 1;

[0046] Inside the transmission box 3, a main shaft driving device 4 for driving the main shaft 1 to rotate in a circumferential direction and an inner shaft driving device 5 for driving the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com