Mushroom cultivating material and manufacturing method thereof

The technology of mushroom cultivation material and production method, which is applied in the field of edible mushroom cultivation, can solve the problems of low utilization rate of biogas residues, pollute the environment, waste of resources, etc., and achieve the effects of widening cultivation raw material channels, reasonable ratio and accelerated growth rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

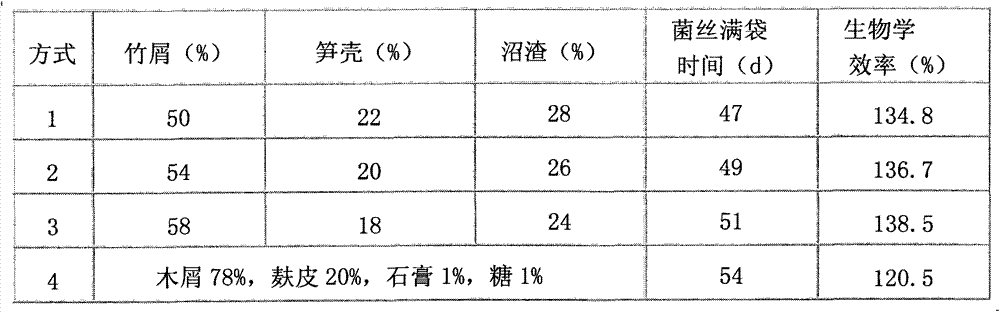

[0023] Method 1: In this embodiment, the mushroom cultivation material includes the following components and mass proportions: 50% of bamboo chips, 22% of bamboo shoot shells, and 28% of biogas residue.

[0024] Production Method:

[0025] ①Pour bamboo chips and dry bamboo shoot shells into the blender and stir well, then add water slowly and mix while adding to keep the water content of the mixture at 60%-63%;

[0026] ②Add biogas residue and stir evenly to keep the water content of the cultivation material at 62%-65%;

[0027] ③A high-pressure polyethylene bag tube with a folding width of 15cm, a length of 60cm, and a thickness of 0.05mm is used. The standard of the bacterial stick is the length of the material column (45±1)cm, and the weight of the bacterial stick is (2.25±1)kg;

[0028] ④ Sterilize the fungus sticks under normal pressure. When the temperature in the pot reaches 100°C (after discharging the cold air), keep it for 10h-12h, and then cool it naturally to belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com