Particle size control method and application of dialkylphosphinate salt

A technology of dialkyl phosphinate and alkyl phosphinate, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of large particle size, flame retardant Reduce efficiency, limit applications and other issues, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

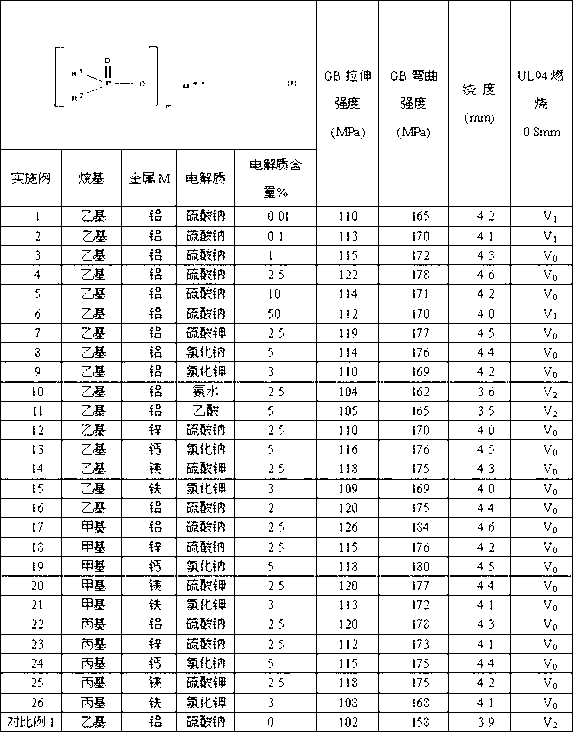

[0038] Embodiment 1: the preparation of aluminum diethylphosphinate

[0039] Heat 976g (0.8mol) of 10% diethylphosphinic acid solution to 70°C, add 0.01% mass fraction (based on the mass of diethylphosphinic acid solution) of sodium sulfate solution, neutralize with alkali, 45min Add 444g of a mixture of 20% aluminum sulfate (M=666) and water dropwise to form a white solid, cool, filter, wash the precipitate with 2L deionized water, and dry at 180°C for 20h to obtain diethylphosphinic acid Aluminum 101.4g, yield 97.5%, moisture content 0.4%;

[0040] Tap density (g / L): 610; Particle size (μm) distribution: D(10): 10.325; D(50): 26.382; D(90): 53.254;

[0041] IR: 778cm -1 , 1076 cm -1 , 1151cm -1 , 2881 cm -1 , 2959 cm -1 .

Embodiment 2

[0042] Embodiment 2: the preparation of aluminum diethylphosphinate

[0043] Same as Example 1, heat 244g (1mol) of 50% diethylphosphinic acid solution to 100°C, add 0.1% mass fraction (based on the quality of diethylphosphinic acid solution) of sodium sulfate solution, use alkali For neutralization, add 370g of a mixture of 30% by mass aluminum sulfate (M=666) and water dropwise within 40 minutes to form a white solid, cool, filter, wash the precipitate with 2.5L of deionized water, and dry at 180°C for 20 hours to obtain di Aluminum ethyl phosphinate 123.5g, yield 95.0%, moisture content 0.8%;

[0044] Tap density (g / L): 618; Particle size (μm) distribution: D(10): 9.054; D(50): 14.152; D(90): 22.384.

Embodiment 3

[0045] Embodiment 3: the preparation of aluminum diethylphosphinate

[0046] Same as Example 1, heat 305g (0.5mol) 20% diethylphosphinic acid solution to 150°C, add 1% mass fraction (based on the quality of diethylphosphinic acid solution) of sodium sulfate solution, use Alkali neutralization, add dropwise a mixture of 111g of 50% by mass aluminum sulfate (M=666) and water within 0.1h to form a white solid, cool, filter, wash the precipitate with 1L of deionized water, dry at 180°C for 20h, and prepare 61.2 g of aluminum diethylphosphinate was obtained, with a yield of 94.2% and a moisture content of 0.9%;

[0047]Tap density (g / L): 625; particle size (μm) distribution: D(10): 6.586; D(50): 10.581; D(90): 18.469.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap