Perforated pipe for consolidating foundation

A foundation reinforcement and porous pipe technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems that affect the promotion and application of MJS construction technology and the high cost of imported porous pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

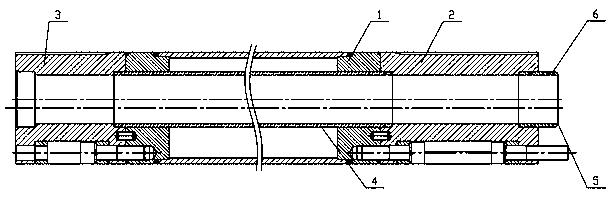

[0012] Such as Figure 1 to Figure 2 As shown, the porous pipe used for foundation reinforcement of the present invention includes a porous pipe main pipe 1, a long joint assembly 2, a short joint assembly 3, a long oil pipe assembly 4, a short oil pipe assembly 5, two sets of quick joints 6, and the like.

[0013] A long oil pipe assembly 4 is installed in the middle of the orifice pipe main pipe 1, and the two ends of the orifice pipe main pipe 1 are respectively sealed and fixedly connected to the long joint assembly 2 and the short joint assembly 3, and the other end of the long joint assembly 2 is sealed and fixedly connected to the short oil pipe assembly (5).

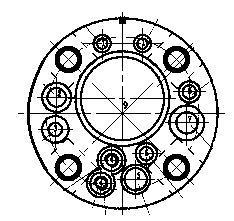

[0014] Such as figure 2 As shown, the perforated pipe is provided with fifteen holes: four of which are threaded holes used to connect components; three are used for ventilation holes; two holes are used for oil to act on the switch of the mud discharge switch; Two holes for cutting holes for water; one for ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com