Underground cavity extra-large dome excavating construction method

A technology for underground caverns and construction methods, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of unfavorable large-scale construction facilities, increased construction risk, and high cavern dome height, and achieves reduction of construction difficulty and safety. The effect of reducing the risk, reducing the excavation span and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

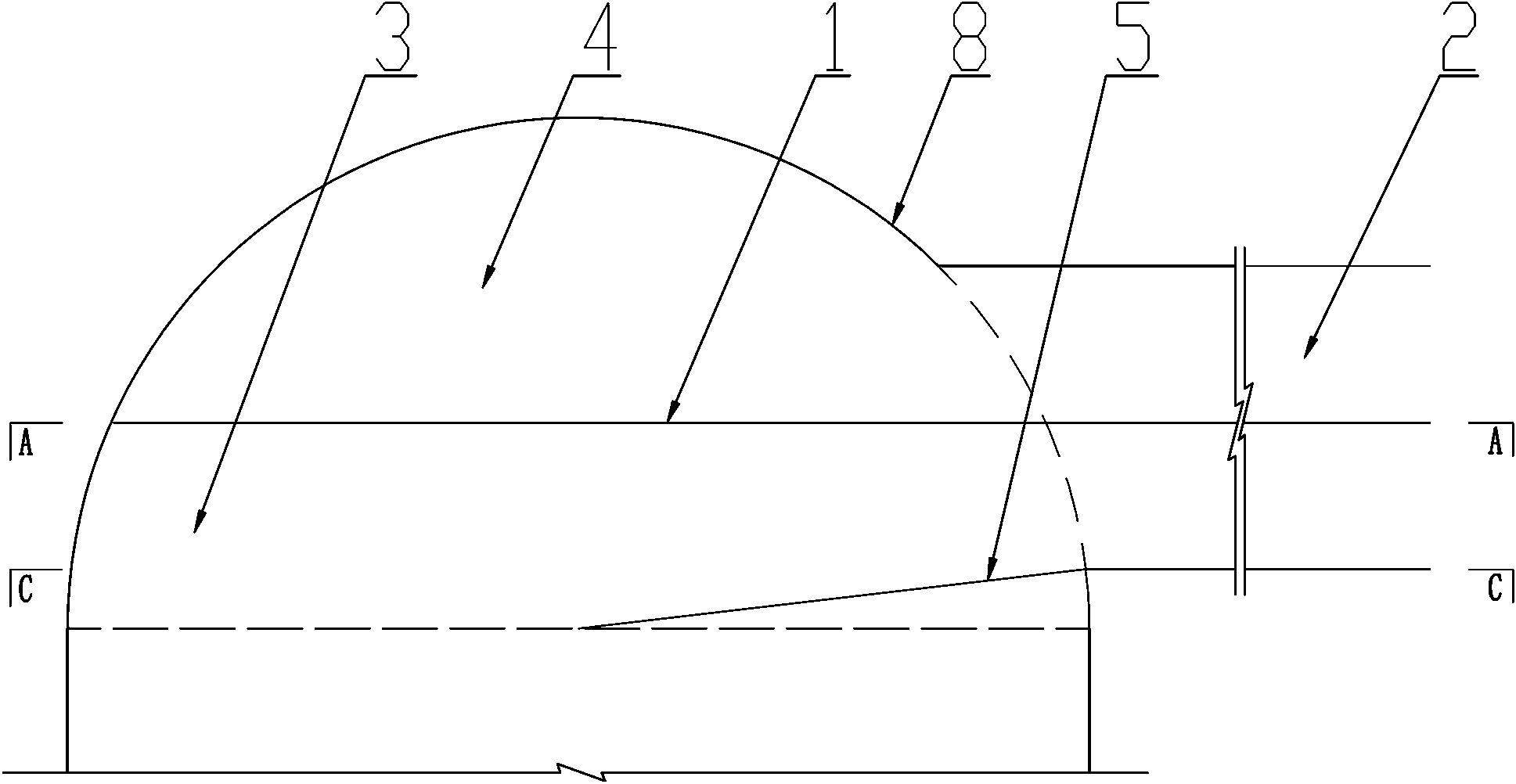

[0036] like Figure 1-8 Among them, a construction method for excavating an extra-large dome in an underground cavern, comprising the following steps:

[0037] 1. Layer the dome chamber 8 and the guide tunnel 2 connected thereto according to the upper and lower layers; specifically as figure 1 As shown in , in this example, the dome chamber 8 and the pilot tunnel 2 are divided into two layers. like figure 1 The first layer 4 and the second layer 3 bounded by layer line 1 are shown in . The construction sequence in the design is to excavate the first layer 4 first, and then excavate the second layer 3, so that the construction height is controlled within a range that is convenient for construction. In this example, the heights of the upper and lower layers of the pilot tunnel 2 are approximately equal.

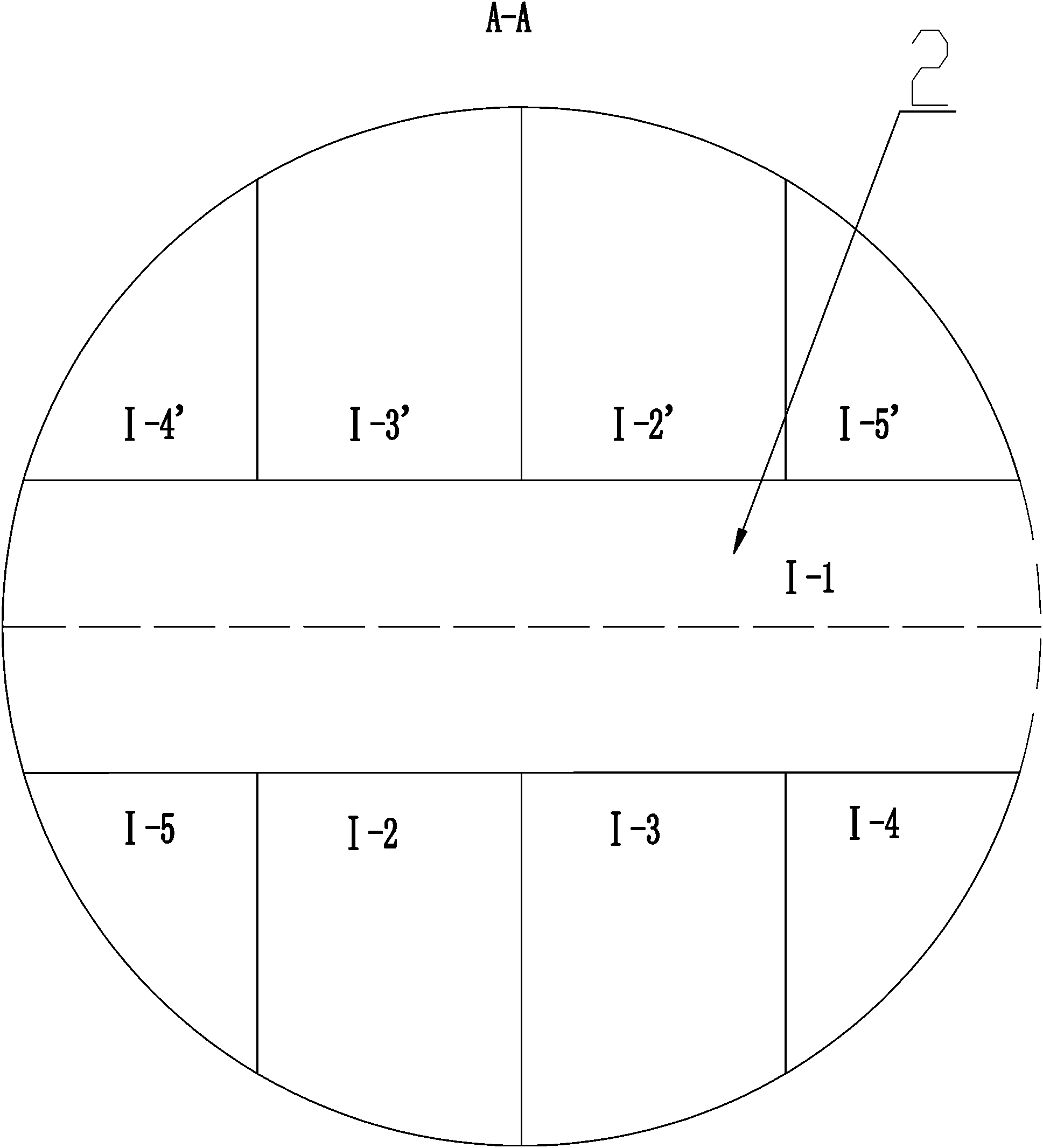

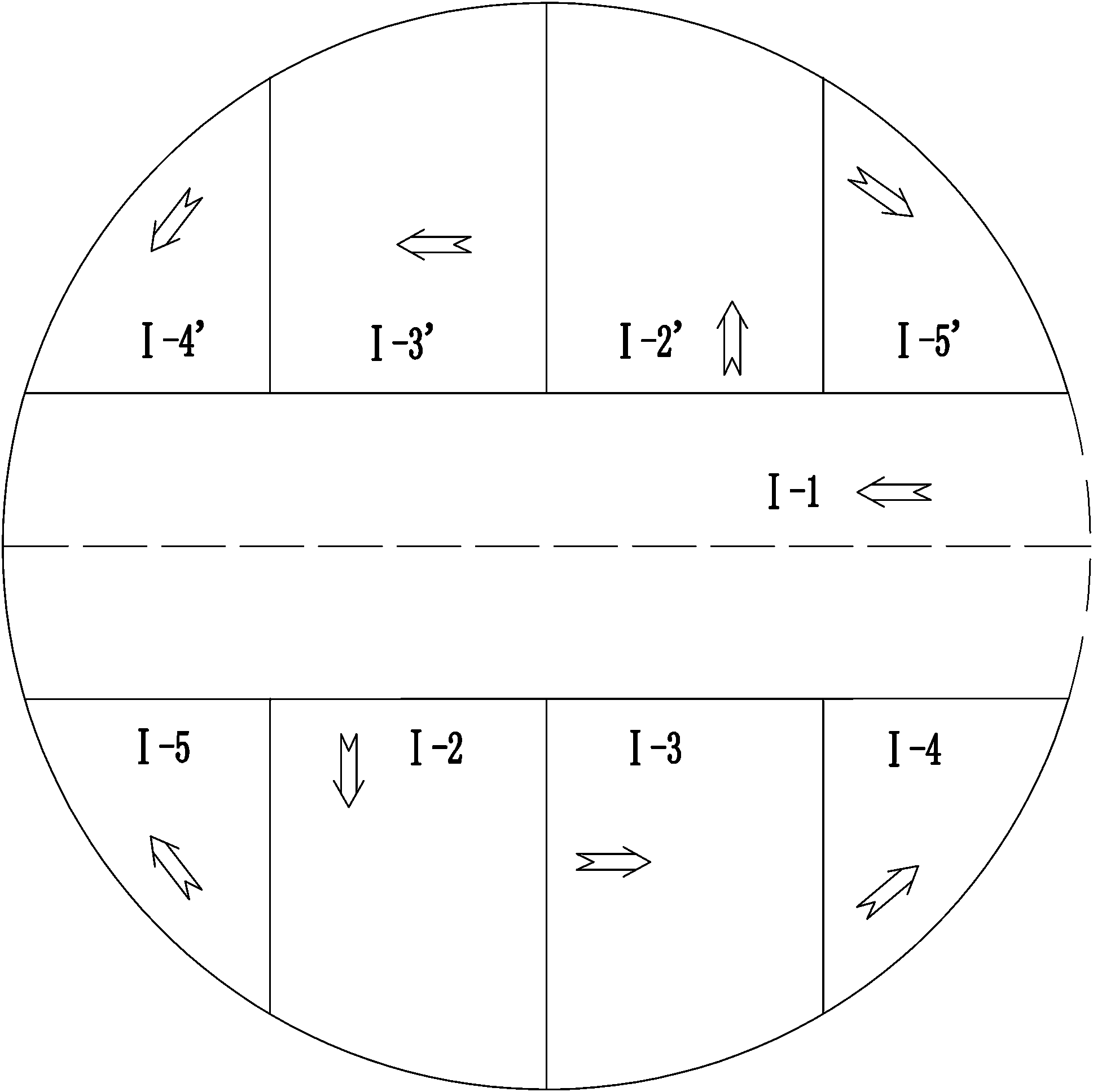

[0038] 2. The dome chamber 8 is symmetrically divided into multiple areas with the pilot tunnel 2 as the axis; specifically as figure 2 , 6 as shown in figure 2 , is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com